Diamond blades might sound fancy, but they’re all about function over flair. Designed for serious cutting power, these blades are made with a mix of diamond grit and metal to handle tough materials like concrete, brick, and stone. Whether you’re working on a large-scale construction project or a smaller DIY renovation, diamond blades are an essential tool for getting the job done efficiently.

Diamond blades are engineered cutting tools bonded with synthetic diamond particles on a metal base. They efficiently cut tough materials like concrete, brick, and stone, making them essential for construction and DIY projects. Known for durability and precision, diamond blades provide clean, long-lasting performance, ensuring efficient and reliable cutting every time. The diamonds are either attached through sintering (fusing under heat) or brazing, which creates a strong, durable edge. These synthetic diamonds aren’t like the ones you’d find in jewelry; they’re industrial-grade and specially engineered for high performance. The result is a blade that can withstand intense heat and pressure, making it perfect for the hardest materials.

It’s amazing how much strength is packed into these blades, don’t you think? But there’s more to these tools than just the raw power they bring to the table. Let’s dive deeper into what makes diamond blades so unique and how they can be used in a wide variety of applications.

Are Diamond Blades Real Diamonds?

Diamond blades can sound like they’re straight from a jewelry store, but there’s a bit of reality-check involved here. The diamonds used in these blades aren’t about glitz and glamour—they’re all about performance.

Diamond blades do use real diamonds, but not the shiny gemstones used in jewelry. Instead, they are made with synthetic industrial diamonds, which are much more affordable but just as tough. These diamonds are bonded to the blade’s edge, allowing it to cut through concrete, stone, and even steel. It’s all about their hardness—diamonds are the hardest naturally occurring material, which makes them perfect for cutting tough surfaces.

Understanding Synthetic Diamonds

Unlike the diamonds on your engagement ring, the diamonds in these blades aren’t meant to sparkle. Synthetic diamonds1 are produced under controlled conditions, mimicking the natural formation of diamonds but in a lab. They come in different grit sizes, which influences how fine or rough the cut will be. The blade’s segments, where diamonds are embedded, are the secret to its cutting efficiency.

For practical purposes, synthetic diamonds provide the same hardness as natural ones, without the cost or rarity. And let’s be real—when you’re trying to cut through concrete, you’re not looking for sparkle, just pure efficiency. Synthetic diamonds have the advantage of being consistent in quality, and they can be customized for specific cutting tasks. This customization means manufacturers can produce blades tailored to different applications, whether for fast, rough cuts or for clean, precise work.

The use of synthetic diamonds also offers environmental benefits. Mining natural diamonds can be a resource-intensive and environmentally challenging process, whereas synthetic diamonds are created in a controlled setting. This makes the production more predictable and less impactful, which is an important consideration in today’s world where sustainability is increasingly a key focus.

Moreover, the versatility of synthetic diamonds means they can be designed to withstand different temperatures and wear conditions, making them suitable for an incredibly wide range of applications. From construction to renovation projects, the unique properties of these diamonds ensure that diamond blades remain effective, even under the most demanding circumstances.

The Bonding Process

Another fascinating aspect of diamond blades is the bonding process. The diamonds are held in place by a metal matrix, which is carefully designed to wear down at the same rate as the diamonds. This controlled wear is essential because, as the metal wears away, new diamond particles are exposed, keeping the blade sharp. It’s like having a blade that continuously sharpens itself, ensuring that it maintains peak performance over its lifespan.

The bonding process can vary depending on the type of blade and its intended use. There are two main methods: sintering and brazing. Sintering involves pressing the diamond particles and metal powder together under high heat and pressure, creating a solid bond. Brazing, on the other hand, involves using a filler metal to bond the diamonds to the blade at a lower temperature. Each method has its own advantages, and the choice between them depends on the specific requirements of the blade.

Sintered blades are often used for dry cutting, as they can withstand higher temperatures without the need for cooling. Brazed blades, on the other hand, are typically used for wet cutting, where water is used to keep the blade cool and reduce dust. Understanding the differences between these methods can help you choose the right blade for your project, ensuring that you get the best performance and longest life out of your tool.

What are Diamond Blades Used for?

Diamond blades are versatile tools, but it’s easy to underestimate their full range of uses. These blades are a staple in construction and renovation, and their applications are as varied as the materials they cut through.

Diamond blades are used for cutting a variety of materials, such as concrete, asphalt, stone, ceramic tiles, and even glass. These blades are popular in construction, demolition, and renovation projects where precision and toughness are crucial. Depending on the blade type and diamond concentration, they can tackle anything from delicate tile cutting to breaking down large slabs of concrete.

Diamond blades are also commonly used in roadwork and infrastructure projects. Cutting through asphalt and reinforced concrete is no small feat, and diamond blades are up to the task. They are used to create expansion joints in concrete slabs, cut through thick asphalt layers, and even shape natural stone for landscaping projects.

Applications in Everyday Projects

I’ve seen these blades used everywhere—from major construction sites cutting through reinforced concrete to small DIY home projects where someone is just trying to cut a tricky tile. The key here is versatility. Contractors use these blades to efficiently tackle tough materials, while DIYers might find comfort in knowing they have a tool that won’t wear out after a single use. They’re also preferred for their ability to make clean, precise cuts2, which is essential when you’re dealing with materials like granite or ceramics that can easily crack or chip if mishandled.

When it comes to tile work, diamond blades are a game-changer. Cutting ceramic or porcelain tiles with a traditional blade can be frustrating, as the material tends to chip or crack. Diamond blades, on the other hand, provide a clean cut that minimizes the risk of damage. This is especially important when working with expensive or delicate tiles, where even a small mistake can be costly.

In addition to tiles, diamond blades are also used for cutting natural stone, such as granite and marble. These materials are incredibly hard and can be difficult to work with, but diamond blades make the job much easier. Whether you’re installing a new countertop or creating a custom stone feature, a diamond blade is the tool you need to get the job done right.

Another common use for diamond blades is in cutting concrete and masonry. Whether you’re installing a new driveway, building a retaining wall, or working on a foundation, diamond blades are essential for cutting through these tough materials. The ability to make precise cuts is crucial in these applications, as it ensures that the finished product is both functional and aesthetically pleasing.

Industrial and Specialized Applications

Beyond everyday construction and DIY projects, diamond blades have specialized uses in industrial settings. For example, they are used in the production of precision components, where materials like glass and ceramics need to be cut with extreme accuracy. In these applications, diamond blades are often used with specialized saws that can make incredibly fine cuts, ensuring that each component meets exact specifications.

Diamond Blade Selection Guide?

Choosing the right blade can feel overwhelming—especially if you’re new to the world of power tools. With so many options available, it’s important to understand the differences between various types of diamond blades and how to choose the one that best suits your needs.

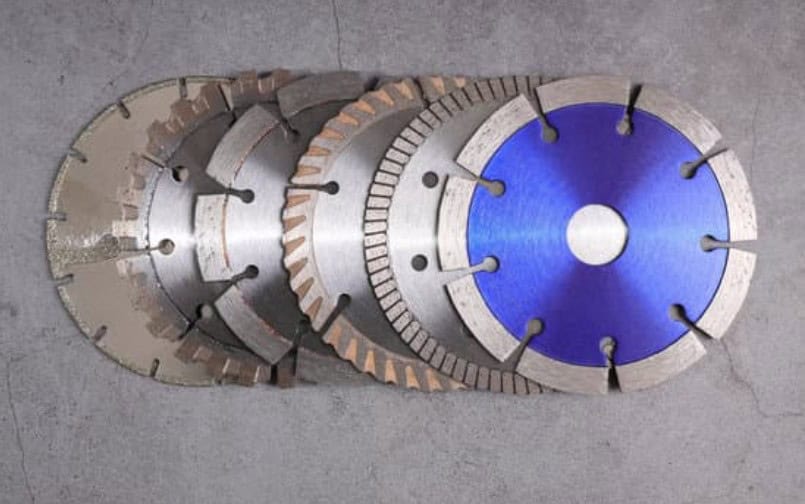

The right diamond blade depends on the material being cut, the type of saw used, and the desired cutting precision. Different blades are made for different applications. Segmented blades are ideal for rough cuts in concrete and brick, while continuous rim blades are best for smooth cutting of ceramic and glass. Turbo blades fall somewhere in between, providing a good balance of speed and precision.

Picking the Perfect Blade

If you’re anything like me, you probably want to get the best tool for the job without overcomplicating things. A good rule of thumb is to match the blade type with the material—segmented blades for hard, rough materials and continuous rims for finer, brittle surfaces. The turbo blade is like your all-purpose player, good for when you’re unsure. Plus, understanding the RPM rating3 of your saw is key; not all blades are suitable for every machine, so make sure they’re compatible to avoid wear or, worse, accidents.

Here’s a simple breakdown:

| Bıçak Tipi | Best For |

|---|---|

| Parçalı Bıçak | Concrete, Brick |

| Turbo Bıçak | Masonry, Multi-purpose |

| Sürekli Jant | Ceramic, Glass |

This table can help take some of the guesswork out of your next project.

Blade Types Explained

-

Bölmeli Bıçaklar: These blades have distinct segments separated by gullets, which allow for better airflow and cooling. This makes them ideal for cutting through thick, dense materials like concrete and brick. The segments also help to dissipate heat, which is important when cutting through materials that generate a lot of friction.

-

Turbo Blades: Turbo blades combine the features of segmented and continuous rim blades. They have a serrated edge that provides faster cutting while still maintaining a relatively smooth finish. These blades are versatile and can be used for a wide range of materials, making them a great choice for general-purpose cutting.

-

Sürekli Kenar Bıçakları: As the name suggests, these blades have a continuous edge, which makes them ideal for cutting through delicate materials like ceramic and glass. The smooth edge provides a clean cut, reducing the risk of chipping or cracking. Continuous rim blades are typically used with water to keep them cool and reduce dust.

Choosing the Right Bond

Another important factor to consider when selecting a diamond blade is the bond. The bond is the material that holds the diamond particles in place, and it plays a crucial role in the blade’s performance. There are two main types of bonds: soft and hard.

- Soft Bond: A soft bond wears away quickly, exposing new diamond particles more frequently. This makes it ideal for cutting hard materials like granite or concrete, where the blade needs to remain sharp to maintain cutting efficiency.

- Hard Bond: A hard bond wears away more slowly, which is better for cutting softer materials like asphalt or limestone. The slower wear rate ensures that the blade lasts longer, providing better value for the money.

Understanding the different bond types can help you choose a blade that will perform well for your specific application. If you’re not sure which bond to choose, consider the material you’re cutting and how often you’ll be using the blade. For most DIY projects, a soft bond blade is a good choice, as it will provide the sharpness needed to cut through tough materials.

How Diamond Blades Work?

Have you ever wondered what actually makes these blades work so well? It turns out that the science behind diamond blades is both fascinating and surprisingly straightforward. Unlike traditional saw blades, which cut by slicing through materials, diamond blades work by grinding them away.

Diamond blades work through a grinding action, rather than the cutting action typical of regular saw blades. As the blade spins, the diamond particles grind away the material, creating fine dust. The blade’s metal bond wears down gradually, exposing new diamonds, which keeps the blade sharp and ready for more cutting.

The Science Behind the Grind

Think of a diamond blade like a pencil sharpener for hard surfaces. Each diamond particle acts like a tiny, tough grinder, chipping away at stone or concrete one layer at a time. The trick to their efficiency lies in how the diamonds are embedded in the metal matrix. As the outer layer wears down, more sharp diamonds are revealed, keeping the blade at its best. This is why these blades don’t get dull the way a regular saw blade might—they constantly renew their cutting edge.

And here’s something else that’s pretty cool: the speed of the blade4 actually helps keep it cool. The segments provide room for air to circulate, which prevents overheating and ensures the blade doesn’t wear out prematurely. This cooling effect is especially important when cutting through materials that generate a lot of heat, like concrete or asphalt.

Factors That Affect Blade Performance

Several factors can influence how well a diamond blade performs, including the type of material being cut, the speed of the saw, and the amount of water used during cutting. Understanding these factors can help you get the best results from your blade and extend its lifespan.

-

Material Hardness: The hardness of the material you’re cutting plays a significant role in how well the blade performs. Harder materials require a blade with a soft bond, as this will expose new diamonds more quickly, ensuring that the blade remains sharp. Softer materials, on the other hand, can be cut with a blade that has a harder bond, as the wear rate will be slower.

-

Hız kesmek: The speed at which the blade spins also affects its performance. A higher speed can help the blade cut more efficiently, but it also generates more heat, which can lead to premature wear. It’s important to find the right balance between speed and cooling to ensure that the blade performs well without wearing out too quickly.

-

Water Use: Water is often used with diamond blades to keep them cool and reduce dust. This is especially important when cutting materials like concrete, which generate a lot of heat. Using water helps to prevent the blade from overheating, which can cause the metal bond to break down and the diamonds to become dislodged. In addition to cooling, water also helps to reduce dust, making the cutting process cleaner and safer.

The Role of Segment Design

The design of the blade’s segments also plays a crucial role in its performance. The segments are the parts of the blade that contain the diamond particles, and they are designed to wear down at a controlled rate, exposing new diamonds as the old ones become dull. The shape and spacing of the segments can affect how well the blade cuts and how long it lasts.

- Wide Spacing: Blades with wide spacing between segments are ideal for cutting materials that generate a lot of debris, like asphalt or concrete. The wide spacing allows for better debris removal, which helps to keep the blade cool and prevents it from becoming clogged.

- Narrow Spacing: Blades with narrow spacing between segments are better for cutting materials that require a smooth finish, like tile or glass. The narrow spacing provides more continuous contact with the material, resulting in a cleaner cut.

Understanding the role of segment design can help you choose the right blade for your project, ensuring that you get the best performance and the longest lifespan from your tool.

Çözüm

Diamond blades are all about precision and toughness, making them the tool of choice for cutting through some of the hardest materials around. Whether you’re a professional or just tackling a DIY project, knowing what makes these blades work helps you get the best results. The right blade, proper use, and understanding of the underlying technology will make all the difference in achieving a smooth, efficient cut every time.

-

Understand the advantages, such as consistency, cost-effectiveness, and superior cutting performance compared to natural diamonds. ↩

-

Technical advantages of diamond blades, emphasise the ability to minimize material damage during cutting. ↩

-

RPM rating ensures user safety and maximizes blade performance, emphasising the significance of matching blade and saw specifications. ↩

-

Blade speed is a critical factor for both efficiency and durability, explains how speed impacts cooling and prevents blade wear during intense applications. ↩