Spot Weld Drill Bits

Spot weld drill bits are available in a variety of sizes and shapes, and they can be used in both corded and cordless drills. When shopping for a spot weld drill bit, it is important to select the correct size and type for the job.

Smaller spot welds can be drilled out with a standard drill bit, but larger spot welds may require a specialized spot weld drill bit.

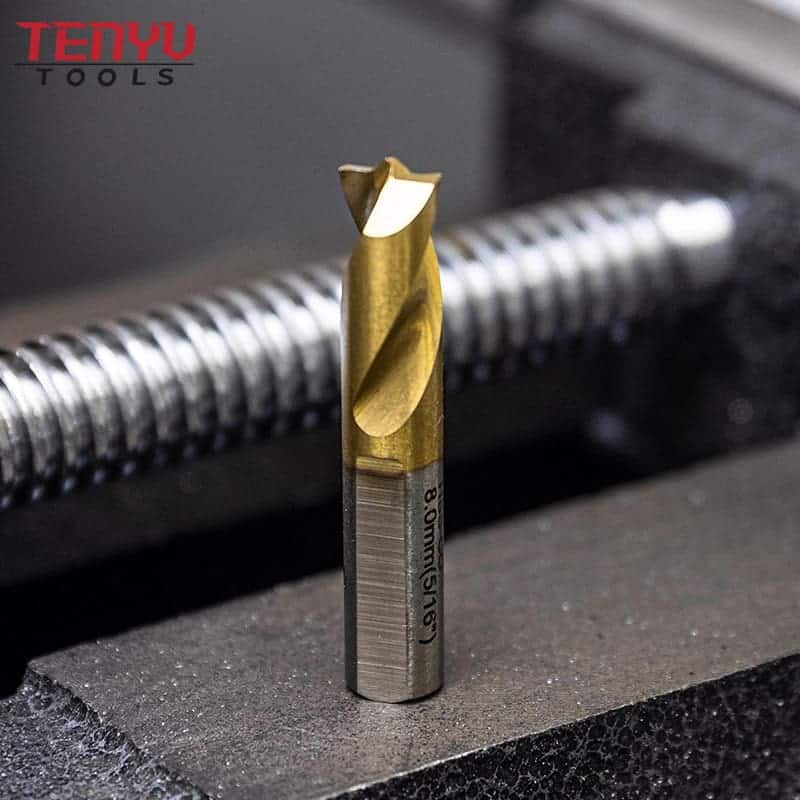

Tenyu Spot Weld Drill Bit Picture

Why Tenyu

Spot Weld Drill Bits

Unrelenting Customer Support We never get tired of giving our clients the support and assistance they need! Do you have a question before the sale? Do you yearn to learn more about our lineup of taper length drill bits and can’t decide which one to go with? Contact us and we’ll answer all your questions and concerns!

Expertise and Professionalism Our employees all have a combined experience amounting to 70 years in blacksmithing and in toolmaking. We’re sure that we’ll be able to produce the exact taper length drill bits you need for your business!

Progressiveness and Flexibility Tenyu Tools Co., Ltd. breeds on new products and we you will never have any trouble if you want to innovate or be different compared to other suppliers and manufacturers in the industry. In terms of creativity, you can absolutely count on us!

Swift and Fast Delivery With Tenyu Tools Co., Ltd., you’ll never have a problem when it comes to delivery. We’re known for lightning-speed delivery. Thanks to our partnerships with some of the country’s top courier, as well as freight and cargo services, we can get you the orders in less than two (2) months!

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

What is a Spot Weld Drill Bit?

A spot weld drill bit is a specialized type of drill bit that is designed for drilling out spot welds. Spot welds are commonly used to join thin sheets of metal together, and they are often found in auto body panels.

Drill bits are usually made of high-carbon steel or HSS, and they have a conical point that is used for drilling out spot welds.

The drill bit is inserted into the spot weld and rotated at a high speed, which breaks the spot weld and separates the two sheets of metal.

How Big Should Spot Weld Holes Be?

Spot welding is a popular technique for joining metal workpieces together. However, one of the challenges of spot welding is getting the right size hole for the weld.

This can be achieved with a spot weld drill bit. These bits are designed to create clean holes of the correct size for spot welding, making the process much easier and ensuring that the weld is strong and durable.

Professional HSS Spot Weld Drill Bit

Are Spot Welds Strong?

When spot welding, two pieces of metal are placed together and an electrical current is passed through them. This creates heat and pressure, which fuse the metals together.

Spot welds are strong enough for many purposes, but there are certain limitations to keep in mind. For one, spot welding can only create localized joins. This means that the weld will only be as strong as the surrounding area.

Additionally, the strength of a spot weld depends on the force and temperature that has been applied. If the current is not strong enough or if the metal is not heated to a high enough temperature, the weld will be weak.

Finally, spot welds are only as strong as the cleanliness of the electrodes and metal. If there is any dirt or debris on either surface, it will weaken the connection.

Strong Spot Weld Drill Bit

Spot Weld Drill Bit Scenes to Be Used

While spot welds are extremely strong, they can be a weak spot when it comes to car restoration or auto body repair work.

A spot weld drill bit is the professional’s choice for removing spot welds, and with two types of spotweld cutters available, removing spot welds is easier than ever.

The first type of spot weld cutter is the standard spot weld drill bit, which is designed for use with a power drill. The second type of spot weld cutter is the pneumatic spot weld drill bit, which is designed for use with an air compressor. Pneumatic spot weld cutters are more powerful than standard spot weld cutters and can easily remove spot welds in even the most difficult to reach places.

Whether you’re a professional or a do-it-yourselfer, a spot weld drill bit is an essential tool for any car restoration or auto body repair project. Spot welding is a commonly used method for joining two pieces of metal together, and the spot weld drill bit is the tool of choice for removing spot welds.

This type of drill bit is designed to cut through the metal without damaging the underlying panel, making it an ideal tool for repairing spot welds or for making new spot welds. The spot weld drill bit is also an essential tool for removing spot welds from Boron and other UHSS metals.

Other spot weld cutters may damage the underlying panel, but the spot weld drill bit leaves the panel undamaged and can be quickly removed. As a result, the spot weld drill bit is an essential tool for anyone who works with spot welds.

How far Apart Should Spot Welds be?

When spot welding, it is important to ensure that the distance between the two welds is a minimum of 10 times the material thickness. This will help to ensure adequate joint strength and allow for the use of standard electrodes. screw extractor Overlap of individual sheets being spot welded is also necessary to obtain sufficient joint strength. If you are unsure of the appropriate distance or overlap for your project, consult a professional welding engineer or fabricator. By following these guidelines, you can help ensure a successful spot welding project.

Is Spot Welding Easy?

When screwing in a new light bulb, it is important to not overtighten it. Doing so could strip the threads and make it difficult to remove the bulb in the future.

The same principle applies to spot welding. If the distance between two welds is too small, it can weaken the joint and make it more difficult to remove the sheets later on.

This ensures that there is sufficient overlap between individual sheets, leading to a strong joint that can be easily removed if necessary. So next time you’re spot welding, keep this advice in mind to ensure a strong, long-lasting joint.

Easy Wpot Welding

[toc]