Spot Weld

Spot-weld drill bits are used in handheld drills to drill out a spot weld that is holding two or more thin sheets of metal together.

Tenyu Spot Weld Picture

Why Tenyu

Spot Weld

Unrelenting Customer Support We never get tired of giving our clients the support and assistance they need! Do you have a question before the sale? Do you yearn to learn more about our lineup of taper length drill bits and can’t decide which one to go with? Contact us and we’ll answer all your questions and concerns!

Expertise and Professionalism Our employees all have a combined experience amounting to 70 years in blacksmithing and in toolmaking. We’re sure that we’ll be able to produce the exact taper length drill bits you need for your business!

Progressiveness and Flexibility Tenyu Tools Co., Ltd. breeds on new products and we you will never have any trouble if you want to innovate or be different compared to other suppliers and manufacturers in the industry. In terms of creativity, you can absolutely count on us!

Swift and Fast Delivery With Tenyu Tools Co., Ltd., you’ll never have a problem when it comes to delivery. We’re known for lightning-speed delivery. Thanks to our partnerships with some of the country’s top courier, as well as freight and cargo services, we can get you the orders in less than two (2) months!

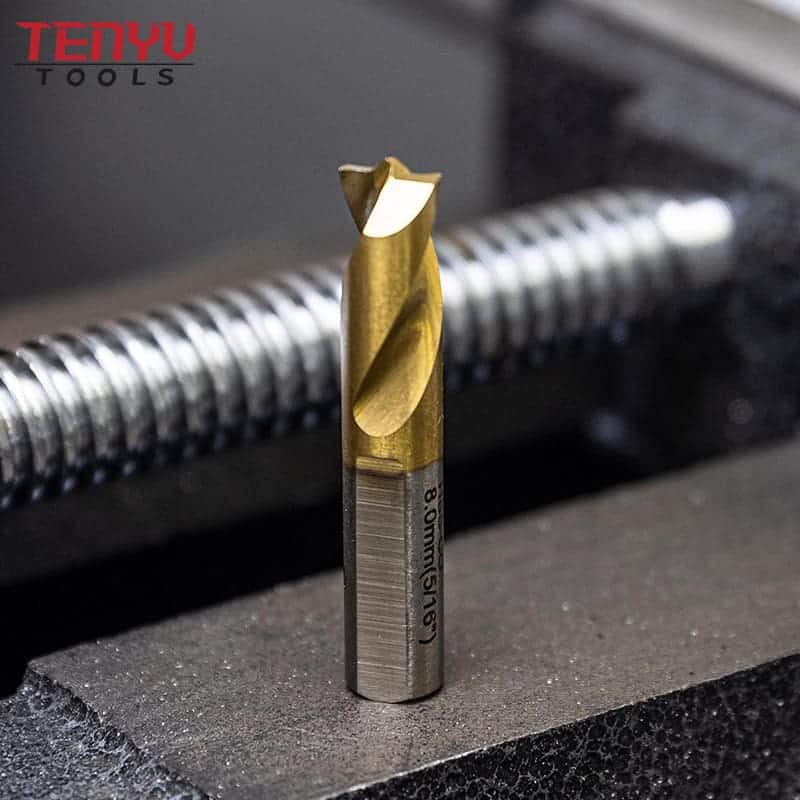

Flat Ground 3 Flutes 8mm Solid Carbide Straight Shank Spot Drill Bit to Prevent Walking

HSS Rotary Spot Drill Bit Remover Weld Cutter Carbide Drill Bit Designed for Spot Weld Drilling

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

What is a Spot Drill Used For?

A Spot Drill is a critical tool when starting to drill a hole. The usage of a Spot Drill is to create a small divot so the center of the drill is correct when initiating a plunge.

If the center of the drill is not in the right spot, it can cause damage to the material being drilled and cause problems down the road. For this reason, Spot Drills are an important tool in any machinist’s toolbox.

In addition to their primary purpose, Spot Drills can also be used to chamfer the top of drilled holes. This leaves a small chamfer that allows screw heads to sit flush with the part once inserted.

This can be especially important in applications where there is not a lot of room for tolerance. Whether used for locating the center of a hole or for creating a chamfer, Spot Drills are a versatile and essential tool for any machinist.

Profession Factory HSS M35 Spot Drill Bits

What is the Difference Between a Center Drill and a Spot Drill?

Spot drills are much thinner than center drills.

Spot drills are also more accurate in drilling a starting point. Center drills are used to drill a hole in the center of a workpiece, while spot drills are used to drill a hole at a specific location on a workpiece.

Spot drills are usually used to drill a hole for a screw or bolt, while center drills are used to drill a hole for a dowel pin.

Spot Drill Bit for an Accurate Drilling

How Deep Should a Spot Drill Be?

Spot drilling is a common machining operation used to create a small hole at the center of a workpiece.

The spot drill is a specialized type of drill bit that is designed for this specific purpose. When choosing a spot drill, the diameter of the bit should be about 70% of the final drill diameter.

The point angle of the bit should also be greater than or less than the final drill’s point angle.

How to Use Spot Drill Bit

Can you Chamfer with a Spot Drill?

Spot drills are commonly used to create a small indentation in a workpiece prior to drilling. This helps to prevent the drill bit from “walking” across the surface of the material.

Spot drills can also be used for chamfering a hole prior to drilling.

This technique is often used when preparing holes for tapped holes, as it creates a small countersink for the tap to start in. Spot drilling can also be used to create a pilot hole for larger diameter drills.

When using a spot drill for this purpose, it is important to take care not to drill too deeply, as this can damage the drill bit. Spot drilling is a versatile tool that can be used for a variety of tasks in the metalworking shop.

How to Chamfer with a Spot Drill

What is a Spot Weld Drill?

Spot welds are small and difficult to drill out with a regular drill bit, but a spot-weld drill bit is specifically designed for this task. The tip of the bit is sharp and slightly concave, which helps it to bite into the spot weld. The body of the bit is fluted to help remove metal shavings as you drill. Spot-weld drill bits are available in a variety of sizes to fit different Drill models.

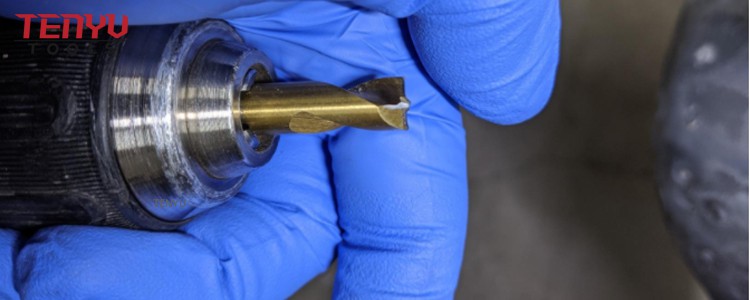

To use a Spot-Weld Drill, simply set the drill to reverse and press the tip of the bit against the center of the spot weld. Apply pressure and hold the trigger down as you slowly guide the drill around the edge of the spot weld.

Continue drilling until the spot weld has been completely removed. They make it quick and easy to remove spot welds, with minimal damage to the underlying material.

How many Flutes Does a Spot Drill Have?

Spot drills are drilling tools that are used to create a small hole in order to mark the center of a future hole.

Spot drills typically have two flutes, which helps to keep the drill bit from walking on the surface of the material. Spot drills are often used in screw machine and Swiss lathe applications because they provide a more accurate way to mark the center of a future hole.

Our 1535 Spotting Drill is stocked uncoated and with FC-7 coating, and it is the preferred choice for many applications. With its two flutes, the 1535 Spotting Drill is an excellent tool for creating accurate holes in a variety of materials.

[toc]