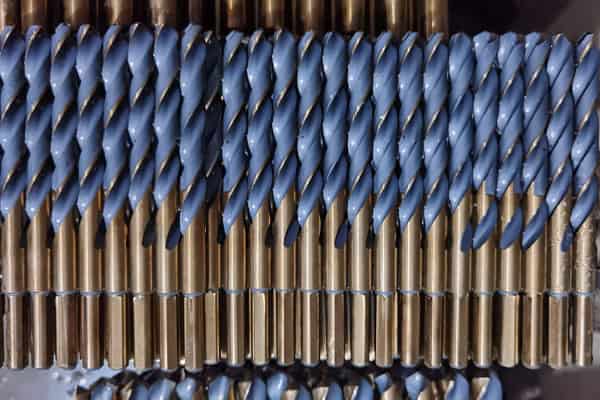

Metal drill bits are essential tools in various industries, but which country excels in producing the best quality?

China remains the global leader in metal drill bit manufacturing due to its large-scale production capabilities and well-established supply chains. However, countries like Germany and South Korea are emerging as strong contenders, offering precision and high-quality solutions that cater to specific industrial needs.

While it’s valuable to know that China, Germany, and South Korea are key players in metal drill bit production, understanding what makes them stand out will allow businesses and consumers to make more informed decisions. Let’s take a closer look at the factors driving their success and how they compare.

China’s Dominance in Metal Drill Bit Manufacturing

China’s manufacturing capabilities have made it a giant in the global metal drill bit market.

China has long been a leader in manufacturing metal drill bits thanks to its extensive infrastructure, large-scale production capacity, and highly efficient supply chains. The country can produce a wide variety of drill bits at competitive prices, making it the preferred source for many companies looking for affordable solutions without compromising on quality.

Advanced Manufacturing Technology

China’s manufacturing sector benefits from cutting-edge technology, including automated production lines and advanced heat treatment processes. These technologies ensure high precision, durability, and consistency in every metal drill bit produced. Automated systems also help keep production costs low, which is a key factor in China’s competitive edge1 in the global market.

Efficient Supply Chains

China’s well-established and vast supply chain network ensures that manufacturers have quick access to raw materials, tooling equipment, and logistics services. This network reduces lead times, helping manufacturers meet tight deadlines and respond quickly to fluctuating demand.

Skilled Labor Force

China has a large and skilled workforce trained in the production of high-quality tools. The combination of experienced labor and ongoing investments in skill development programs ensures that the country can continue to meet global demand with precision.

Competitive Pricing Strategies

China’s ability to scale production and optimize operational costs allows manufacturers to offer metal drill bits at competitive prices. This is especially appealing to businesses in industries such as construction, automotive, and manufacturing, where cost-efficiency is a critical factor.

Innovation, Research and Development

Chinese manufacturers consistently invest in R and D to improve product performance. Recent innovations have focused on producing drill bits that are more wear-resistant, corrosion-resistant, and suitable for a wider range of materials. These advancements have solidified China’s reputation as an industry leader in both low-cost and high-performance drill bits.

How Germany and South Korea Are Gaining Ground

While China leads in volume and scale, countries like Germany and South Korea are gaining attention for their precision, advanced engineering, and high-quality manufacturing practices.

Germany’s Precision and Quality

Germany is known for its high standards of craftsmanship and engineering excellence. German manufacturers are renowned for producing metal drill bits with exceptional durability and precision, making them highly sought after in industries that demand the utmost reliability, such as aerospace and automotive manufacturing.

Technological Innovation

German companies are at the forefront of innovation, developing specialized coatings and advanced alloy materials that enhance the performance of metal drill bits2. These innovations not only extend the lifespan of drill bits but also improve their efficiency, even in the most challenging drilling applications.

South Korea’s Cost-Effective Solutions for High-Quality Products

South Korea’s growing reputation in the metal drill bit market is due to its combination of advanced manufacturing capabilities and competitive pricing. The country has invested heavily in precision engineering, producing drill bits that offer a balance of high quality and affordability. South Korea’s strategic location also makes it an appealing choice for companies looking to diversify their supply chains.

Which Factors Should Businesses Consider When Choosing a Metal Drill Bit Manufacturer?

Selecting the right metal drill bit manufacturer is critical for businesses that rely on precision tools. Factors to consider include production capacity, material quality, technological capabilities, and cost-efficiency.

Production Capacity and Scalability

The ability of a manufacturer to meet large orders or scale up production to accommodate growth is crucial. China’s vast manufacturing base is well-equipped to handle high volumes, while smaller countries like Germany may offer more specialized solutions but with a smaller output.

Material Quality and Durability

The quality of the materials used in the production of metal drill bits, including high-speed steel (HSS), carbide3, and cobalt alloys, directly impacts performance and longevity. German manufacturers, for example, are known for using premium materials to create drill bits that withstand extreme wear and tear.

Technological Capabilities

Evaluating the technological capabilities of manufacturers is essential, as it determines the precision and performance of the final product. Advanced coatings, heat treatments, and laser technology are often used to enhance drill bit efficiency and lifespan.

Custo-benefício

Cost is always a significant factor in the decision-making process. Countries like China and South Korea can offer metal drill bits at competitive prices, while Germany’s premium products often come with a higher price tag due to their precision and advanced engineering.

What Are the Emerging Trends in Global Metal Drill Bit Production?

The global metal drill bit industry is evolving, with trends like sustainability, technological integration, and the increasing demand for custom solutions shaping its future.

Sustainability in Manufacturing

Eco-friendly practices are becoming more prevalent in metal drill bit production. Manufacturers are focusing on sustainable sourcing of raw materials, reducing waste through efficient manufacturing processes, and adopting environmentally friendly packaging solutions.

Technological Integration

The integration of digital tools and automation continues to transform the metal drill bit industry. AI and machine learning algorithms are being used to optimize manufacturing processes and ensure precise quality control. Moreover, advanced coatings4 and material treatments are improving the performance and lifespan of drill bits, making them more reliable for demanding tasks.

Customization and Personalization

Customized metal drill bits, tailored to specific applications or customer preferences, are gaining popularity. Manufacturers are offering greater flexibility in design and materials, enabling businesses to get precisely the tools they need for unique projects.

The Impact of Global Supply Chain Dynamics

The shift in global supply chain dynamics, including the effects of geopolitical tensions and supply chain disruptions, has led manufacturers to explore alternative sourcing options. Countries like India and Vietnam are emerging as competitive alternatives to China, offering a mix of cost-effectiveness and quality.

Conclusão

When choosing the best metal drill bit manufacturer, businesses must carefully consider factors like production capacity, cost, and quality. While China leads in large-scale production, countries like Germany and South Korea provide high-precision options that cater to specialized needs. Understanding the unique advantages of each manufacturing hub allows businesses to make informed decisions based on their specific requirements.

Whether looking for affordable, high-volume options or precision-engineered drill bits, companies can find the right manufacturer by assessing these key factors. As the industry continues to innovate and adapt to global shifts, staying informed about emerging trends is crucial for maintaining a competitive edge.

-

How technological innovation and efficient manufacturing processes can give countries an advantage in the international market, making them more competitive. ↩

-

Understand the factors that contribute to the effectiveness of metal drill bits, including material composition, heat treatment, and design features. ↩

-

Carbide drill bits are known for their hardness and longevity. Learn why carbide is often chosen for drilling through tougher materials. ↩

-

Learn more about the latest developments in coatings, which enhance the durability and effectiveness of drill bits, making them suitable for more demanding applications. ↩