DIN 1869 extra-long drill bits benefits:

- Quick drilling;

- Convenient and quick chip removal;

- On-time delivery of items;

- Consistent quality, extensively used in hard material drilling;

- Extensive expertise;

- Reasonable price.

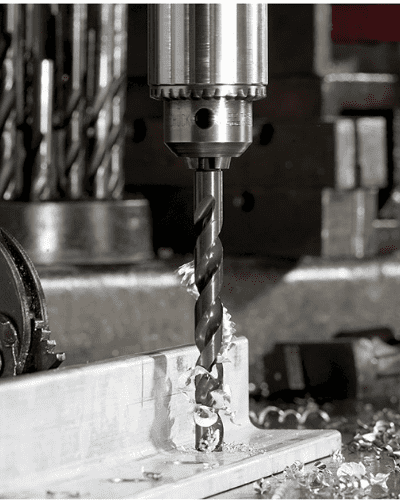

Pictures for You Can Compare Extra Long DIN 1869 drill Bits

Picture for Best Quality Extra Long DIN 1869 drill Bits

DIN 1869 Drill Bit Suit:

- DIN 1869 extra-long drill bits, Investments, since they have a longer lifespan.

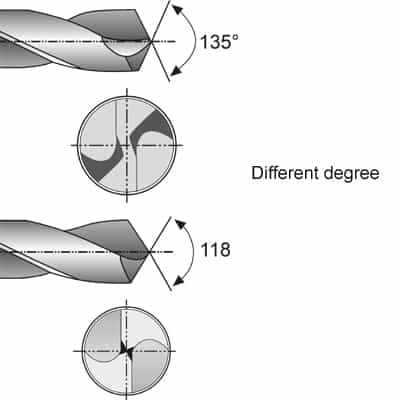

- There is no need for a center punch since the aggressive 135° rapid cut point automatically aligns and enters swiftly with minimal pressure. You can’t “walk” or “wander.”Universal 118° drill tip form for drilling in a range of materials.

3.Extreme precision and performance are achieved through precise grinding points, grooves, bodies, clearances, and bit sizes.

- DIN 1869 Drillbits are suited for a wide range of commercial and industrial operations.Twist drill bits are constructed of high speed steel, which is robust and durable.

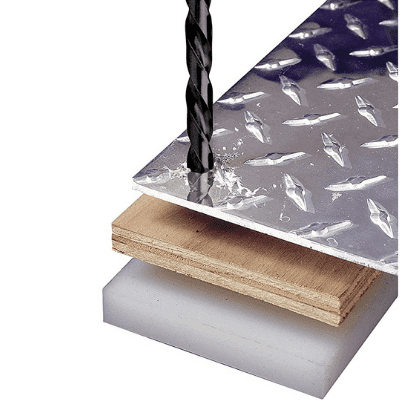

5.DIN 1869 extra-long drill bits have a wide range of uses and are appropriate for most drilling activities as well as soft materials such as aluminum, wood, and plastics.

DIN 1869 DRILL EXTRA LONG DRILLING INTO DIFFERENT MATERIAL

DIN 1869 drill bits extra-long cutting edge, these bits can drill deep holes.

They are suitable for the majority of drilling tasks as well as soft materials such as aluminum, wood, and plastics. Drilling will become easier and easier with the sharp twist drill bit.

Material of high quality: Twist bits are constructed of high speed steel, which is robust and durable.

Convenient and useful: The extra-long cutting edge is perfect for general-purpose usage of the electric hand drill, allowing you to reach areas that little bits cannot; sharp auger bits will make drilling easier and easier.

The material’s toughness, abrasion resistance, and drilling ability are all excellent. Wood, plastic, and aluminum alloy materials are all suitable. Ideal for do-it-yourself, residential, and general construction/engineering projects.

Pictures for Extra Long DIN 1869 drill Bits Can Drilling Different Material

The most common type of bit is a twist drill. The drill bit’s handle is fastened by the machine tool to provide rotational motion. Straight or tapered handles are available. The body of the bit is typically composed of two spiral grooves known as grooves. These grooves are characterized by a spiral Angle, which is normally about 30 degrees but can vary depending on the workpiece’s material qualities. The tip of the bit normally has an Angle of 118 degrees, a rear Angle of 10 degrees, and a cross edge. The chisel edge is flat, and the web thickness is around 0.015 x bit diameter. The edge can pose complications with hole placement because it might “wander” on the surface before engaging the workpiece. A drill Angle of less than 118° is utilized for brittle materials, whereas a bigger drill Angle and a smaller back Angle are used for ductile materials.

A DIY and industrial market favorite. 118 degree point, general purpose, appropriate for portable and machine drilling. Designed for low and medium carbon steel, cast iron, and wood processing. The 135-degree split point centralizes and decreases thrust automatically. For portable or machine drilling, low tensile strength alloy alloys, stainless steel, and other medium applications are appropriate. Brighten the finish using black oxide, titanium nitride coating, and bronze oxide. Customers will have more options.

Picture of Din 1869 drill bits Degree point

DIN 1869 extra-long drill bits, Various specifications,As a result, it is fairly complete and handy for you to suit your diverse needs.

| D | L1 | L2 | D | L1 | L2 | D | L1 | L2 |

| 2 | 85 | 125 | 6 | 225 | 330 | 9.5 | 280 | 410 |

| 2.5 | 95 | 140 | 6.5 | 150 | 215 | 10 | 185 | 265 |

| 3 | 100 | 150 | 6.5 | 190 | 275 | 10 | 235 | 340 |

| 3 | 130 | 190 | 6.5 | 235 | 350 | 10 | 295 | 430 |

| 3.5 | 115 | 165 | 7 | 155 | 225 | 10.5 | 185 | 265 |

| 3.5 | 145 | 210 | 7 | 200 | 290 | 10.5 | 235 | 340 |

| 3.5 | 180 | 265 | 7 | 250 | 370 | 10.5 | 295 | 430 |

| 4 | 120 | 175 | 7.5 | 155 | 225 | 11 | 195 | 280 |

| 4 | 150 | 220 | 7.5 | 200 | 290 | 11 | 250 | 365 |

| 4 | 190 | 280 | 7.5 | 250 | 370 | 11 | 310 | 455 |

| 4.5 | 125 | 185 | 8 | 165 | 240 | 11.5 | 195 | 280 |

| 4.5 | 160 | 235 | 8 | 210 | 305 | 11.5 | 250 | 365 |

| 4.5 | 200 | 295 | 8 | 265 | 390 | 11.5 | 310 | 455 |

| 5 | 135 | 195 | 8.5 | 165 | 240 | 12 | 205 | 295 |

| 5 | 170 | 245 | 8.5 | 210 | 305 | 12 | 260 | 375 |

| 5 | 210 | 315 | 8.5 | 265 | 390 | 12 | 330 | 480 |

| 5.5 | 140 | 205 | 9 | 175 | 250 | 12.5 | 205 | 295 |

| 5.5 | 180 | 260 | 9 | 220 | 320 | 12.5 | 260 | 375 |

| 5.5 | 225 | 330 | 9 | 280 | 410 | 12.5 | 330 | 480 |

| 6 | 140 | 205 | 9.5 | 175 | 250 | 13 | 205 | 295 |

| 6 | 180 | 260 | 9.5 | 220 | 320 | 13 | 260 | 375 |

| 13 | 330 | 480 |

1.HSS Twist Drill Bits Standard for Different Country |

||

German Standard |

American Stanard |

Set Package |

| DIN338 HSS Twist Drills | Jobber Length Drills | HSS Twist Drill Sets |

| DIN1897 Short Type Drills | Screw Machine Drills | Combination Drill Sets |

| DIN340 Long Type Drills | Taper Length Drills | |

| DIN1869 Long Type Drills | 6″12″18″Long Type Drills | |

| Double Ended Drills | Aircraft Extension Drills | |

| Hex Shank Drills | Double Ended Drills | |

| Reduced Shank Drills | Hex Shank Drills | |

| DIN345 Taper Shank Drills | Three Flats Shank Drills | |

| DIN341 Taper Shank Drills | Reduced Shank Drills | |

| ANSI Standard Taper Shank Drills | ||

DIN 1869 EXTRA-LONG DRILL BITS-HSS TWIST DRILL LIST of CHEMICAL ELEMENTS

| Din 1869 Drill Bits Material NO. | steel NO. | CHEMICAL ANALYSIS (%) | |||||||||

| C | Si | Mn | P | S | Cr | W | Mo | V | |||

| Din 1869 Drill Bits 4241 | W4Mo2Cr4VSi | 0.90 | 1 | 0.30 | ≤0.030 | ≤0.015 | 4.8 | 1.6 | 0.65 | 0.55 | |

| 1.00 | 1.3 | 0.40 | 5.1 | 1.85 | 0.8 | 0.7 | |||||

| Din 1869 Drill Bits 4341 | W4Mo3Cr4VSi | 0.89 | 0.60 | 0.30 | ≤0.030 | ≤0.015 | 3.80 | 3.60 | 2.60 | 1.25 | |

| 0.97 | 1.00 | 0.40 | 4.40 | 3.85 | 2.85 | 1.45 | |||||

| Din 1869 Drill Bits 9341 | W9Mo3Cr4V | 0.78 | 0.20 | 0.30 | ≤0.030 | ≤0.015 | 3.80 | 8.60 | 2.80 | 1.35 | |

| 0.86 | 0.40 | 0.40 | 4.40 | 8.90 | 3.05 | 1.55 | |||||

| Din 1869 Drill Bits M2 | W6Mo5Cr4V2 | 0.81 | 0.20 | 0.30 | ≤0.030 | ≤0.015 | 3.80 | 5.60 | 4.60 | 1.80 | |

| 0.89 | 0.45 | 0.40 | 4.40 | 5.85 | 4.85 | 2.00 | |||||

| Din 1869 Drill Bits cobalt M35 | W6Mo5Cr4V2Co5 | 0.88 | 0.20 | 0.30 | ≤0.030 | ≤0.015 | 3.80 | 5.60 | 4.60 | 1.80 | Co: 4.60 |

| 0.95 | 0.45 | 0.40 | 4.40 | 5.85 | 4.85 | 2.00 | 4.85 | ||||

| Din 1869 Drill Bits cobalt M42 | W6Mo5Cr4V2Co8 | 1.05 | 0.15 | 0.15 | ≤0.030 | ≤0.015 | 3.5 | 1.15 | 9 | 0.95 | Co: 7.75 |

| 1.15 | 0.65 | 0.4 | 4.25 | 1.85 | 10 | 1.35 | 8.75 | ||||