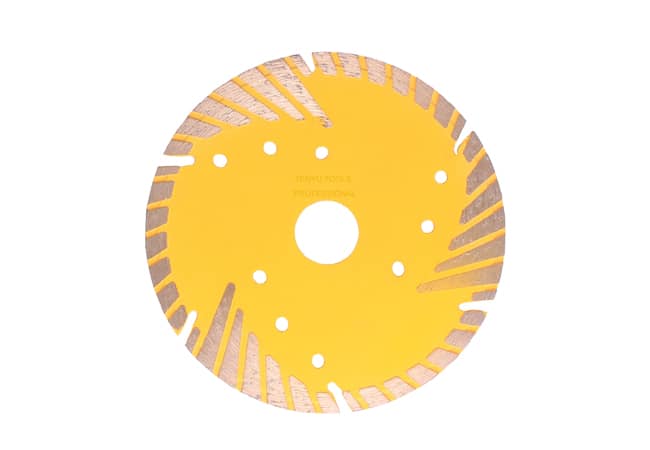

If we want to use diamond saw blade for a long time, we must pay attention to many aspects.

Contents

hide

There are the following points about diamond cutting disc uses.

Pay Attention to the Placement and Fixing of the Material

- Can improve the material yield.

- Reduce unnecessary wear of the diamond saw blade.

Add the Lubricating Fluid on Time and Amount

- Adequate lubrication can reduce friction, reduce noise.

- Increase productivity, and extend the life of diamond saw blades.

The Diamond Cutting Disc Uses Process

- Pays attention to the changes of sawing sound and current at any time.

- If any abnormality occurs, it should be eliminated in time.

The Diamond Cutting Disc Uses to Cut Different Materials of Stone

- Always pay attention to changes in the main motor current.

- Adjust the sawing depth and sawing speed in a timely manner.

The Sparks Caused by the Strong Impact Friction Between the Blade and the Stone Cause Heat When Sawing

- Which needs a sufficient amount of cooling water to cool.

- If the amount of water is insufficient, the cutter head will be burned, so it is necessary to ensure a sufficient supply of water without interruption.

Monitor the Quality of the Sawn Board

Timely check and deal with the influencing factors according to the degree and quantity of the board deviation.

Removing the Diamond Cutting Disc for Storage

It should be hung vertically in order to reduce deformation.

If you want to know more, please contact us!