Oscillating Drywall Blade

- Why Choose Tenyu Tools’ Oscillating Drywall Blades?

- You can get an oscillating drywall blade that is completely made from stainless steel

- Your drywall blades can be customized and custom-made depending on your taste

- You can purchase our 18-in-1 stainless steel oscillating drywall, multi-purpose tool

- You can use it for both indoor and outdoor applications

- You’ll have complete documents of your orders, all legal and certified

- You will be able to receive your orders and packages within 2 to 3 weeks!

- For all your inquiries and concerns, we’ll respond within 12 hours on receipt!

- You can order oscillating drywall blades from us that are all long-lasting and durable!

Tenyu Tools: Your Premier Oscillating Drywall Blade Company

Here in China, Tenyu Tools’ drywall oscillating blade has been seen as the most durable and the best.

Whether you take it from a manufacturer’s perspective, a retailer’s point-of-view, or a business that utilizes it, Tenyu Tools’ oscillating drywall blades are all of a high quality!

We can offer drywall oscillating blades in varying shapes and sizes, depending on how you need it!

Our multi-purpose tool is capable of working on a wide variety of things, not just drywall!

Features and Benefits of Tenyu Tools’ Oscillating Drywall Blades

When you purchase our oscillating drywall blades, you can expect a ton of features and functionalities available.

- Sharper tips, perfect for piercing and cutting into drywall and other materials

- More control in cutting and in producing details in materials and workpieces

- It can give you more accurate and more precise deep cuts

- It’s highly compatible with a lot of power tools and accessories!

- You can create a sketch or a drawing of the tool you’re imagining and have us produce it.

Applications of Our Drywall Oscillating Blades

Do you need help in cutting through drywall? Are you a retailer or a merchandiser and you’re looking to rebrand?

Tenyu Tools Co., Ltd. is the perfect manufacturer for you! We never limit our clients’ capabilities and business advantages!

In fact, we can offer you a ton of discounts and diminished rates for bulk and wholesale oscillating drywall blades!

Our Business Advantages and Capabilities

- We are ISO 9001 and ISO 14001 Certified

- We have SGS and CE Certificates, making us accepted and legal in Europe, Americas, and other continents!

- We have, under our employ, the best and the most skilled engineers and power tools experts!

Tenyu Tools Co., Ltd. is the best and the most trusted oscillating drywall blade manufacturer in the country.

More than a thousand businesses have come to us for assistance and never did we fail them! We’re able to provide original, high-quality, and accurate drywall oscillating blades specific to their need!

Work with us now! Contact us by reaching us via our email or our sales representative. Get a free quote of your order by filling out the quote form on our website!

Never be troubled with how you can source out for the best oscillating drywall blades in the market again!

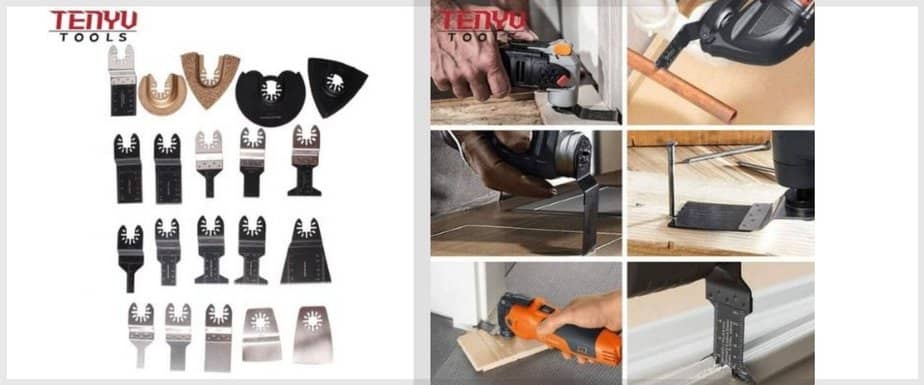

- Manufacturing Machine for Oscillating Drywall Blade

- Detail for Oscillating Drywall Blade

- Oscillating Drywall Blade Using

Oscillating Drywall Blade – The Ultimate FAQ Guide

While you may think it’s easy to look for the oscillating drywall blade that can help you with your project, there are actually a lot of things and factors to consider.

Choosing a drywall oscillating blade is far more than just selecting a tool fit for the job; it actually requires craftsmanship in terms of the results you desire, the speed you want to achieve, the quality of the work, and so forth.

This complete guide about oscillating drywall blades is so comprehensive that you’ll understand each and every part of it. But, if you think that it ends there, think again!

As a bonus, we’ll also give you tips and strategies on how you can land on working with the best oscillating drywall blade manufacturer!

Without further ado, let’s get onto it!

Can You Use Oscillating Blades to Cut Drywall?

Oscillating blades are actually designed to work on a wide variety of materials.

You can use it to work on different types and kinds of wood like hardwood, softwoods, maple, oak, etc. In addition to that, you can also make use of it to work on drywall, tiles, fiberglass, plastic, and many more!

Understanding What an Oscillating Drywall Blade is

In case you’re not familiar with what an oscillating drywall blade is, don’t fret – you’re not alone!

You might find it a little peculiar in understanding what an oscillating drywall blade is, but it’s actually simple.

An oscillating drywall blade basically works by the tool head moving side-to-side in a swift and urgent motion. It’s so fast that it’s capable of cutting through metal – powerful ones can go as high as 20,000 side-to-side movements in just a minute.

Instead of moving back and forth – like how other blades and tools work – oscillating blades’ side-to-side motion, allows more versatility and flexibility in their movement.

What are the Best Oscillating Blades For Cutting Drywall?

The market is filled with a lot of good oscillating drywall blades.

In fact, some of the most notable and the most sought after manufacturers of these blades include Fein, EZARC, Rockwell, Dremel, DEWALT, Ryker Hardware, and Milwaukee.

More often than not, they’re the go-to option of customers and clients when it comes to oscillating drywall blades because of the consistent quality and the reputation they have built over the years of manufacturing.

What Other Uses Can You Have For a Drywall Oscillating Blade

Apart from their original use of cutting drywall, you can use oscillating blades to:

- Scrape off old caulk or glue off of parts and components

- Cut wood flooring in plunges

- Remove or clean away grout

- Trim screws and pipes

- Scrape off rust and other forms of oxidation

- Trim floorboards, wood, and other materials

- Sand furniture down

- And many more!

Because of the motion and the movement suggested by oscillating blades, you wouldn’t experience any shortages on the uses you can have with it!

Purchasing it isn’t for the sole purpose of cutting through drywall – you can find many situations and environments to use it for, too!

Can You Cut a Circle in Drywall Using an Oscillating Blade?

Yes, in fact, you can do it much faster and more convenient than using handheld tools.

Cutting a circle isn’t far from how you would perform a straight cut – you just have to cut it at certain angles in order to result to a round or a circular cut.

Types of Oscillating Blades

There are quite a few classifications of oscillating blades you can find in the market.

And while most of these multi-tools are flexible, you’ll still be able to get the best results if you choose the best oscillating drywall blades for your specific project.

Bi-Metal Blade

Considered as the most common and the simplest blade out of all the other options, bi-metal blades are what’s usually will be fit for whatever project you might have.

The shape and the dimensions of these bi-metal blades are ideal for cutting, shaping, grinding, slicing, etc. But, their primary use is to cut through woods, plastics, fiberglass, drywall, etc.

Semi-Circular Blade

Unlike bi-metal blades, semi-circular blades are circular in form; you can think of it as the ¼ part of a circular saw blade cut and chipped off.

If bi-metal blades are used and are perfect for cutting through wood, plastics, PVC, drywall, fiberglass, and other malleable materials, you can use semi-circular blades to cut through metals, nails, steels, etc.

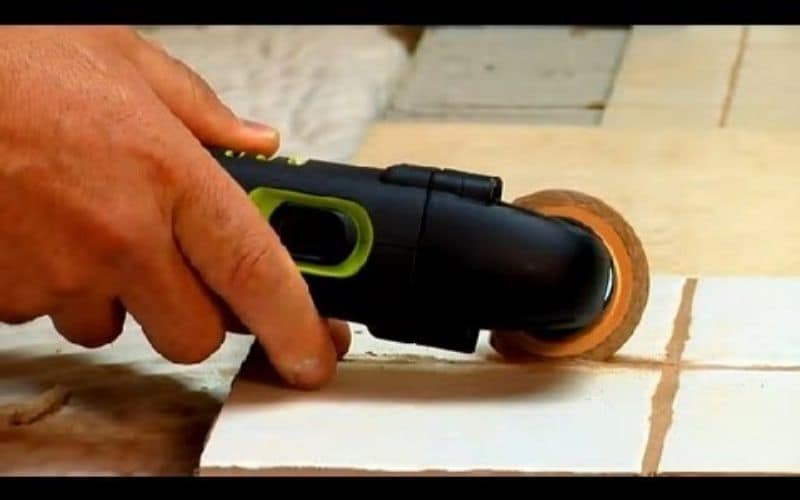

Sanding Pad

Little did we know that drywall oscillating blades are actually useful if you want to sand or grind through certain parts and components.

However, this requires a specific type of attachment to your oscillating tool – the sanding pad. These pads are usually triangular in shape and are used as a buffing tool.

You might find it difficult to order as these are not regular blades and pads. The best way for you to be able to get and order sanding pads is to contact an oscillating blade manufacturer and purchase it in bulk.

Flush Blade

Flush blades are the type of oscillating blades that are able to fit even in tight spaces without losing its power and its overall capacity to cut through a wide array of workpieces and materials.

Because of this, you’ll be able to work on smaller areas and in narrower spaces.

Caulking Blade

The traditional way of removing caulk is by hand, using a cutter or any other type of tool that can fit the job.

While many people consider this as quite a normal task, you can actually save up a lot of time and effort by using an oscillating blade, specifically for caulking.

These scoop-shaped calking blades are ideal for forcing long, thick, and wide strips of caulking in just one pass!

Grout Blade

Last but definitely not the least are grout blades. This technology allowed people and workers to remove grout in between tiles in an automatic way.

With grout blades, you not longer have to remove grout manually – their blades are tipped with highly strong and durable material to carry on with their purpose.

Those are the different kinds of oscillating blades you can choose from. More often than not, you can use them to work on a wide array of drywall types – among others.

Can You Cut Straight Using a Drywall Oscillating Blade?

Yes, as a matter of fact, oscillating blades are perfect if you want to perform a straight accurate cut through drywall.

Simply follow these steps to ensure the precision and the straightness of the cut you’re looking for:

- To make things easier, draw up a straight line using a ruler onto the workpiece or the drywall material you are to cut

- You can use a half-moon or a round oscillating blade

- Power the tool up and let it touch the workpiece by lightly pressing down on your tool

- Avoid going over ¼ inches

- Then, make your blade run all across the length of your sketch or your line

- As you progress, push in and exert more effort, until the line collapses or until the cut is made

NOTE: Avoid putting too much pressure in the beginning – make sure that you don’t exceed ¼ inches deep when you are to start with the cutting procedure.

How Do You Choose the Best Drywall Oscillating Blade?

As you may now know, there are quite a few different types and kinds of oscillating drywall blades you can find in the market.

So, how do you choose an oscillating drywall blade to work with? What are the things and factors you can consider before choosing?

Here are some of the things you need to think about before you purchase a drywall oscillating blade.

Build Up Material

In choosing an oscillating drywall blade, it is worth noting to choose a blade where their durable build-up materials are durable and strong.

This is what’s responsible to help the blade finish its job without breaking.

Speed

Speed is among the many things that you can consider in selecting an oscillating drywall blade.

For instance, how long or how fast you can finish a sanding project can actually be a big factor. In these scenarios, you would want to go for stronger and sturdier blades.

Design and Structure

What your drywall oscillating blades look like is one of the most crucial and important aspects to consider.

Why? – Because the structure and the design of your blade will dictate how comfortably and how conveniently you’ll be able to work with it.

In addition to that, the design of the blade can also dictate how efficient and how effective it will be when you use it to cut through various materials.

Compatibility

Depending on your project and the multi tools you have, you can consider your blade’s compatibility to be probably be the most important factor in choosing a blade.

Would you be comfortable in mounting or attaching a big blade to a small oscillating tool and vice versa?

Choosing an oscillating drywall blade that doesn’t fit or that’s not compatible with your tool is as bad as just not doing it.

Therefore, you need to choose an oscillating drywall blade that’s compatible and that’s effective to work on your multi tool.

Materials to Work With

As far as we remember, there are specific oscillating blades for woods, drywall, PVCs, metal, steel, plastics, fiberglass, glass, and other materials.

In choosing an oscillating blade, you also need to consider what workpieces and materials you need to work with.

How Do You Sharpen an Oscillating Drywall Blade?

Yes, there are several ways on how you can sharpen up oscillating drywall blades, but do you know when the perfect time is to do so?

Some of the most common signs that your oscillating blades need sharpening include:

- If smoke is produced during use

- The color or the shade of your blade is dulled out

- If the blade reflects light

- If you hear vibration and noise that don’t sound too good

Should you experience any of this, don’t hesitate to give your drywall oscilatting blades a sharpening.

When it comes to sharpening, you can choose from a wide range of techniques and strategies. But, we’re going to give you the two (2) best and the most used procedures in sharpening oscillating drywall blades.

Manual Sharpening Method

Firstly, let’s discuss how you can sharpen your blades manually.

Without further ado, here’s how you can perform the manual sharpening method of drywall oscillating blades.

- Place or mount your blade to any tool where you can carefully and stably mount your oscillating blade.

- Hold the saw file on both ends, get one point down on the tooth pallet and stroke it across, each a couple of times.

- Apply light-to-moderate pressure that would be able to cut well.

- Using a magnifying glass, check on each of the oscillating drywall blade’s teeth if they look sharpened or fresh.

NOTE: Usually, a double pass is enough to freshly sharpen an oscillating drywall blade. Moreover, you would be able to sharpen drywall oscillating blades at least five (5) times before their teeth fall out.

Wet Grinding Method

While the wet grinding isn’t actually automated, it’s the more sought after sharpening technique because of its ease.

For wet grinding, all you need to have is an abrasive wheel mounted to a grinder. While the oscillating blade is in place, you just have to run through it.

Multi-Blade Sharpeners

Lastly, you can opt for oscillating saw blade and multi-tool blade sharpeners respectively. This is the fastest, but the most expensive option if you’re looking to sharpen your oscillating drywall blades.

Can You Cut Through Laminated Flooring Using an Oscillating Drywall Blade?

Yes, as a matter of fact, an oscillating drywall blade is the best and the most economical of blades that you can use to work on laminate flooring.

Akin to a jigsaw, you would have less problems and dilemmas to deal with if you decide to choose this blade.

Who is the Best Drywall Oscillating Tool Blade Manufacturer?

Out in the industry, only Tenyu Tools Co., Ltd. has been trusted and seen as the most trusted and the most sought after manufacturer of drywall oscillating blades.

For more than 12 years, we have perfected the craft, providing thousands and thousands of oscillating drywall blades to our clients from all across the globe.

In our experience, we were able to gather 1,000+ clients worldwide, all continuing to trust and bank on us and our services.

Why is Tenyu Tools Co., Ltd. the Best Oscillating Drywall Blade Manufacturer in China?

Choosing Tenyu Tools would be the best decision to make! We are ISO and SGS certified!

You can bank and count on us to help you whether you need pre-made oscillating drywall blades or custom oscillating blades!

Dial us or shoot us an email and get the best-quality oscillating drywall blades in the market!