Industrial Wood Cutter

- Your Trusted and Reliable Industrial Wood Cutter Manufacturer

- You get assurance that all Tenyu Tools’ products are made from premium materials.

- You will experience the cutting-edge technology that we used to manufacture our primary products.

- You will enjoy amazing deals when you do business with Tenyu Tools, China’s leading manufacturer.

- Tenyu Tools can handle large orders.

- We can customize your industrial wood cutter and accessories orders.

You Design It, We Make It!

Professional Industrial Wood Cutter!

Tenyu Tool cutting tool accessories are designed to suit most of the industrial cutters.

To get the value of your investment, it is crucial to check its distinct features and cutting edge advantages.

An Industrial wood cutter is a tool that you use to cut or shape wood materials.

It is a woodcutting essential that provides convenience and quick results.

This useful device helps you achieve your desired cuts and begin your simple to complex projects.

If you are a manufacturer or supplier of wood furniture and other wood products, investing in a top-caliber cutter is vital.

An industrial wood miter saw and other types of the industrial cutting saw will make your woodworking goals easy.

If you are into metal works, your best buddy is an industrial metal cutting circular saw.

A durable, dependable industrial wood cutter is the key to perfection.

Features

- Woodcutting tools come in a variety of shapes, sizes, and designs.

- Picking the best product involves knowing your woodworking needs and materials.

- You need the right tool that is made from the highest-grade material like alloy, carbon steel, and steel.

- It is also important to consider the type of attachments and tool accessories that make them functional.

- Most power tools use5 inserts or easy-to-replace saw blades, milling cutters, and tool bits with a diamond or carbide tip.

- Not all industrial wood cutters are made equal.

- It should be wear-resistant, rust-proof, and durable.

Product Applications

This is why you need to find a suitable saw or cutter for the following applications:

- cabinet making

- furniture making

- woodcarving

- carpentry

- manufacturing building materials like shingles, plywood, and panels

- joinery

- woodturning

A high-performing industrial wood cutter helps you turn softwood, hardwood, or man-made wood into beautiful masterpieces.

Timbers, logs, and rough boards of woods are transformed by manufacturers and contractors into houses and wood products.

Related Products Mention

Having a reliable partner who can fulfill your bulk orders is important to business owners like you.

Tenyu Tools is a perfect choice if you are looking for a trusted and dependable manufacturer-supplier.

It is the leading manufacturer in China with a wide array of power tool accessories for industrial woodcutting tools and machines.

You can choose from a variety of circular saw blades for your hardwood, softwood, plywood, and synthetic wood.

- You get a guarantee that everything you purchase has no defects and flaws.

- You get access to high-quality tool accessories for all types of the industrial wood cutter.

- You can have a wide range of attachments and accessories for woodcutting tools and machines

Call to Action

Would you like to start partnering with Tenyu Tools?

They can help you grow your distributorship and wholesale business exponentially.

Avail of exciting privileges when you import products from Tenyu Tools.

It’s time to take your business to the next level. Call Tenyu Tools now!

Start our new business for industrial wood cutter!

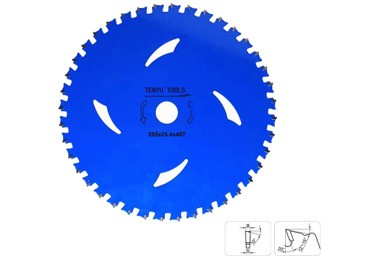

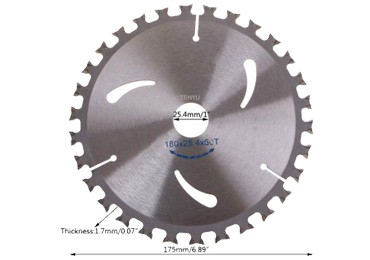

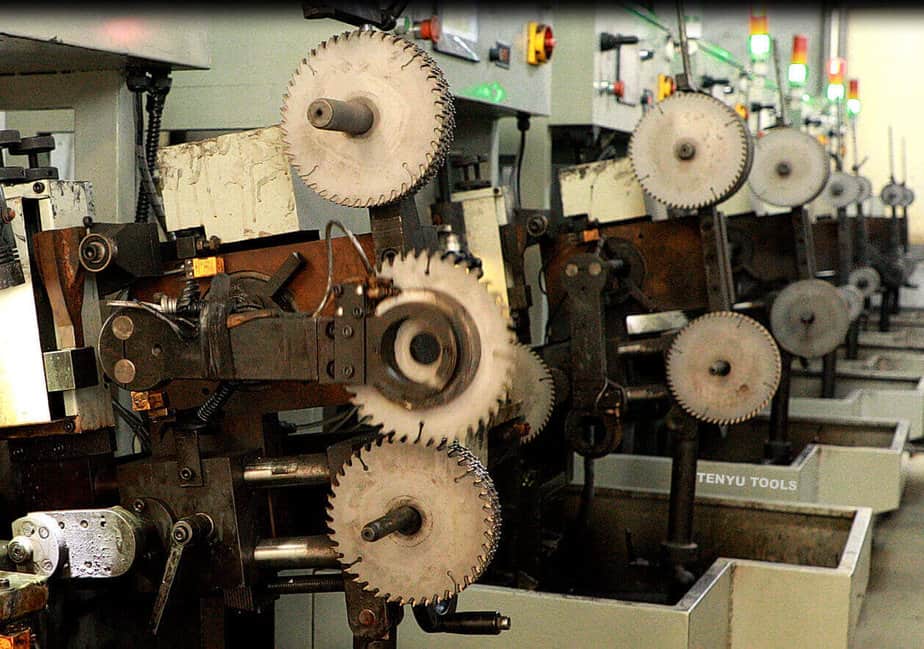

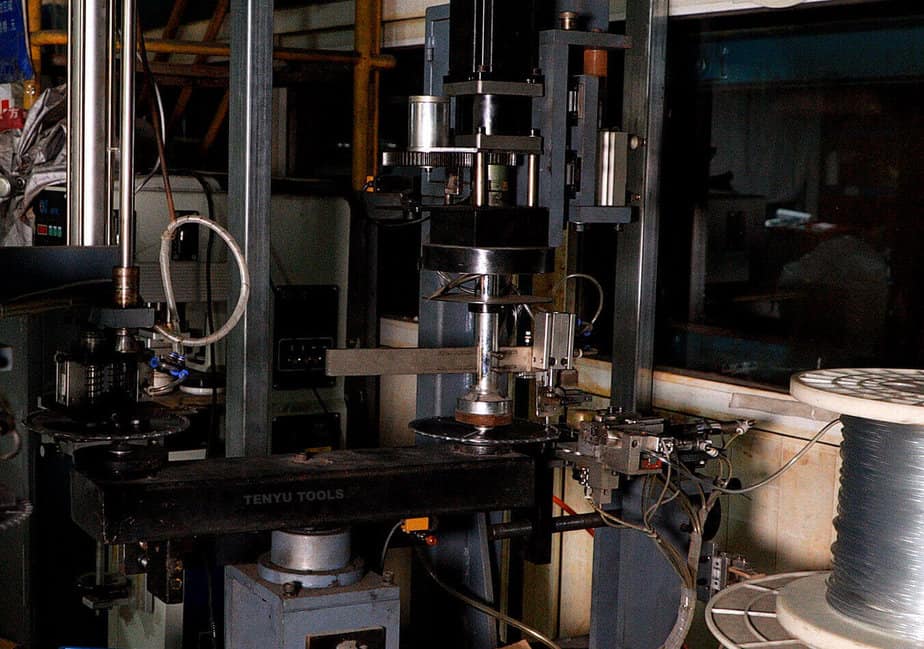

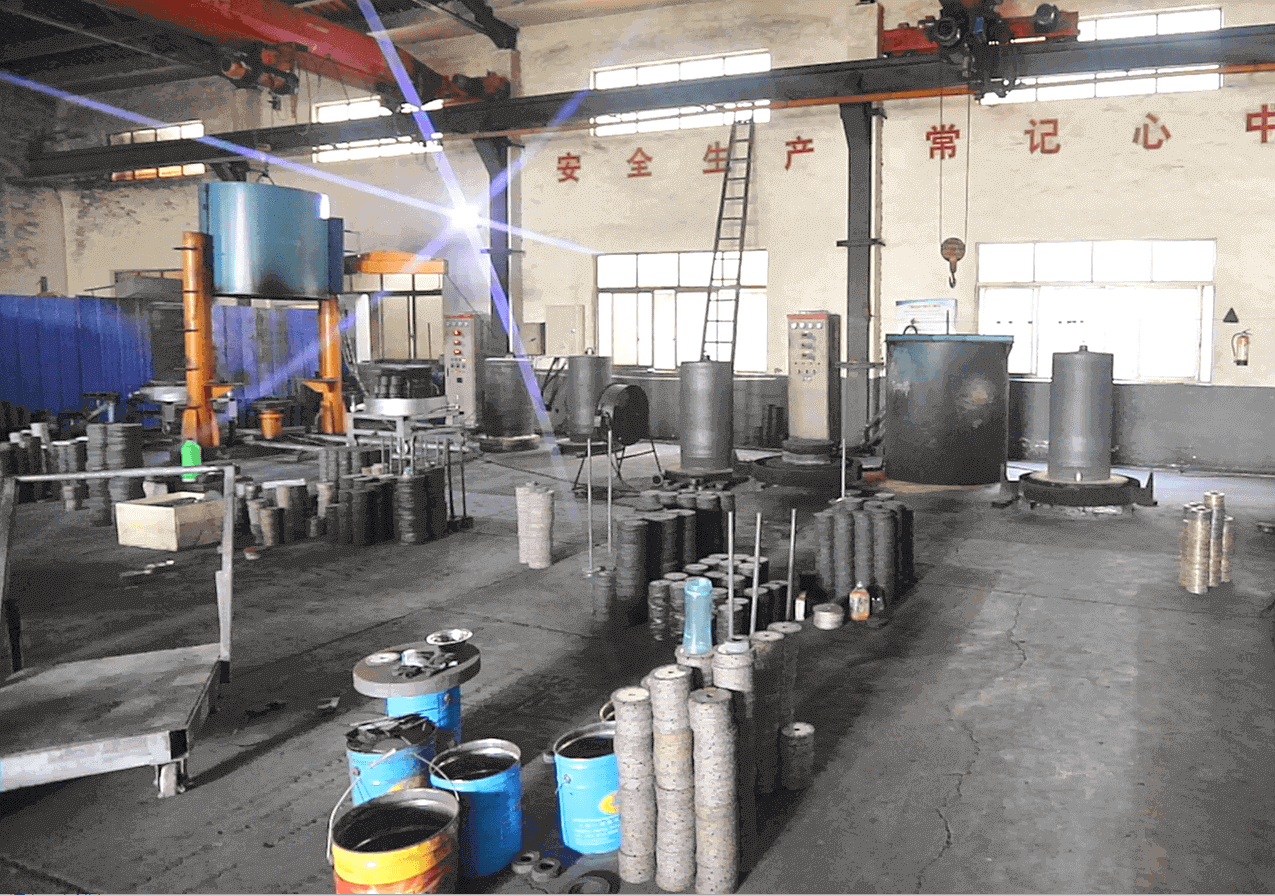

- Manufacturing Machine for Industrial Wood Cutter

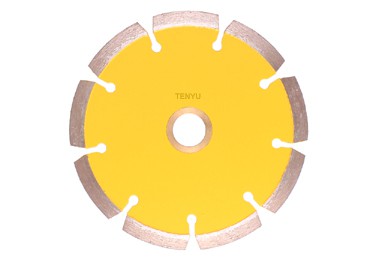

- Detail for Industrial Wood Cutter

Industrial Wood Cutter: The Ultimate FAQ Guide

The core of every woodworking project begins with cutting or shaping the materials.

A high-quality industrial wood cutter is necessary to do this vital operation.

Great finishes are the result of powerful woodcutting equipment.

Finding the right industrial wood cutter is important to get the desired cuts.

Using proper tools with the right attachment or accessory is the key to perfection.

To make the industrial wood cutter selection process simple and quick, here’s a guide for you.

It provides information to help you buy the perfect industrial wood cutter for your needs.

What is an Industrial Wood Cutter?

The industrial wood cutter is an instrument, tool, or machine that changes the size and shape of the wood.

It cuts the material and removes the shavings of the material needed for a variety of purposes.

The elegant wood-made piece of furniture you want to buy is a product of woodcutting tools.

An Industrial wood cutter is also responsible for the wide array of wood home and office accessories.

Woodcutting tools are divided into manual and mechanical tools.

Manual tools

- saws

- axes

- Bits

- Files

- Gouges

- Jointers

- smoothing planes

Mechanical tools

- circular saws in rotary machines

- form cutters and shank cutters in milling machines

- planer knives in planers

- drills, bits, and countersink reamers (counter-bores) in drilling machines

What are the Uses of Industrial Wood Cutters?

Woodworking requires tools to cut, finish, measure, assemble, and hold the parts to transform them into a complete project.

Most projects begin by cutting vital components.

To make it possible, you need a reliable industrial wood cutter.

Cutting tools are used for the following applications:

- cabinet making

- furniture making

- manufacturing building materials like shingles, plywood, and panels

- wood carving

- carpentry

- woodturning

- joinery

In the context of machining, cutting is achieved by single-point or multipoint tools.

Single-point tools help in the following applications:

- shaping

- planing

- turning

- removing materials through one cutting edge

Multipoint tools are for:

- grinding

- drilling

- milling

What are the Characteristics of Industrial Wood Cutters?

The industrial wood cutter should be harder than the material to be cut.

This makes the cutting tool more heat-and-force-resistant during the operation.

Design

The design and geometry of the industrial wood cutter should meet the industry’s required standards for:

- strength

- toughness and hardness

- wear resistance

- long lastingness and durability

- sharp cutting edge

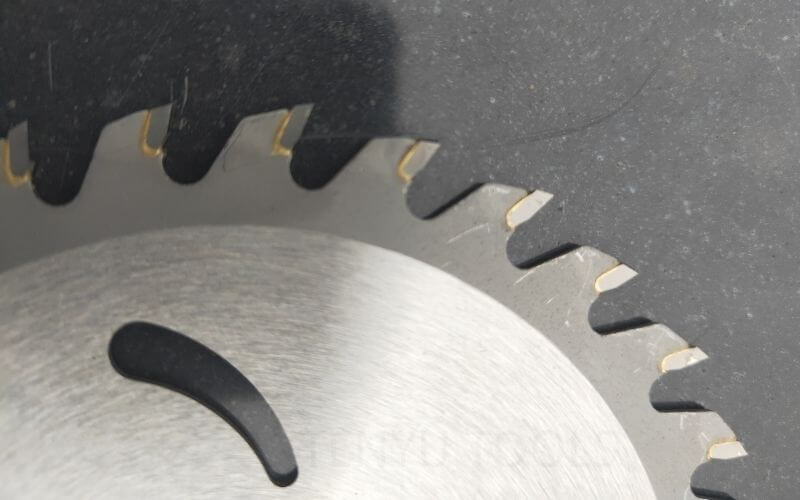

Most of the industrial wood cutters are designed with replaceable tipped tools or inserts.

The cutting edge is clamped, brazed, or welded to the tool body.

Power tools that use inserts include saw blades, tool bits, and milling cutters.

The commonly-used tip materials are diamond, cubic boron nitride, and cemented carbide.

Material

The popular materials used to create industrial wood cutter are:

- alloy

- carbon steel

- certain grades of abrasives and hard alloys

Coating

To ensure greater wear resistance, all cutting devices and tools went through the process of:

- case hardening

- nitriding

- or electrolytic coating

Cutting elements

The following cutting elements of an industrial wood cutter influence its performance and outcomes.

- cutting or clearance angle

- the shape of the cutting face

- form of the radius, trumpet, or radius

- the number of flute and flute width

- form and size of the chamfers

- blade

An industrial wood cutter with a hard alloy blade, for instance, cuts through the cemented wood surface of plywood and fiberboard.

Bracing parts

They work to transmit the cutting force to the units and elements of the machine or tool.

Every woodcutting tool uses particular bracing parts to ensure better precision of operation.

Why Do You Need an Industrial Wood?

Manufacturers of wood products need heavy-duty cutters for more complex projects.

Hobbyists and DIY-enthusiasts invest in wood cutters for simple to complex tasks.

A rough length of wood becomes your canvass to create amazing projects.

Whether you are using hardwood or softwood, the industrial wood cutter gets you going.

Cool trivia: Wood remains a popular material because of its durability, versatility, and sustainability.

It has a natural surface that can be painted or coated, making the finished product stylish and attractive.

Wood is classified into three types:

- Softwood

Softwoods come from gymnosperms or trees that stay green all year round, cone-bearing, and coniferous.

They are more lightweight but less durable because of their lower density.

This type of wood is also more vulnerable to fungal and pest attacks.

Softwoods are popular with general contractors who use them for trimming, framing, and finishing work.

The common softwoods used to make furniture are:

- Cedar

- Pine

- Fir

- Hardwood

Hardwoods belong to the angiosperms.

They are resilient and strong.

They have great properties that suit a lot of purposes.

Aesthetically, the light to the dark color of hardwood is widely-sought.

Hardwoods are resistant to warping and extremely durable.

They are harder to cut and require a heavy-duty industrial wood cutter to get the desired cut.

They cut cleanly and do not leave much residue on the woodworking tools.

Additionally, hardwoods are more expensive and more difficult to acquire.

And while there are many species, only 200 types of hardwood can be used for woodworking purposes.

The common hardwoods used to make furniture are:

- Ash

- Mahogany

- Oak

- Cherry

- Birch

- Maple

- Man-made

They are synthetic or engineered types of wood.

Examples include medium-density fiberboard (MDF) and plywood.

Is There a Minimum Cutting Speed for Industrial Wood Cutters?

In determining the optimum performance of an industrial wood cutter, you need to know their cutting speed and feed rate.

The ideal feed rate of the cutter in woodworking should be fast enough to prevent burning the material.

But it must be slow enough to avoid bogging down the motor.

For instance, maple and black cherry woods are prone to burning, so you need to be careful.

Moreover, a slower feed rate brings finer surfaces.

The industrial wood cutter should deliver a cutting speed of 60 to 100 m/sec and a feed rate of 100-180 m/min.

It will help you achieve a precise and high-quality working surface during the cutting process.

In essence, the cutting speed is defined by these factors:

- inherent precision of the tool

- standardized heat treatment

- precision grinding and sharpening

- balancing and mounting in the machine

It is also important to meet the predetermined requirements for material roughness and dimensional accuracy.

In general, these factors are considered less crucial in woodworking compared to metalworking.

Most power saws and woodcutting tools have fixed RPM rotation.

Most often, the cutting speed of the industrial wood cutter is regulated through its feed rate.

The required feed rate is also variable and depends on the following factors:

- power of the motor

- the sharpness of the industrial wood cutter

- the hardness of the wood

Why are Saws Widely Used as an Industrial Wood Cutter?

Saws are synonymous with cutting.

They have been in use since men learned the basic carpentry skill thousands of years ago.

Today, these humble cutting tools have different types, shapes, designs, and features.

They are also referred to as power saws with niches of their own.

Power saws usually have rechargeable batteries.

They do not require a lot of effort to cut the material, just basic skills to get the desired output.

Industrial saw, in particular, requires premium products that get the tasks done.

Here are 10 industrial cutting saw that you need to check out:

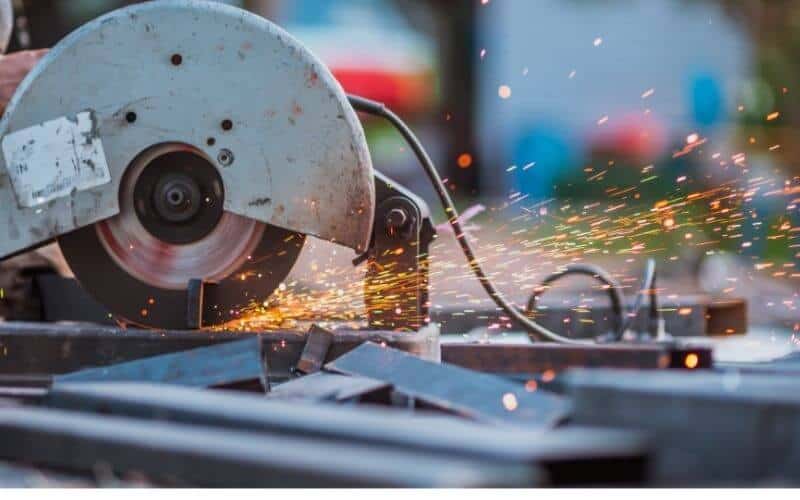

- Circular Saw

The circular saw is an excellent choice for cutting wood, solid wood, and wood panels.

This industrial wood cutter helps you achieve accurate cuts.

It is also capable of cutting other types of materials like stone, metal, plastic, masonry, and more.

If you are using metals as raw materials, you must find a quality industrial metal cutting circular saw.

It accepts a variety of circular blades to cut the material to make crosscuts and rip cuts.

The round blade features sharp teeth that easily tear through the surface.

This industrial wood cutter delivers precise cuts.

It is ideal for processing high volumes of the same material type.

However, the finishes are dependent on the blades you use.

To ensure quality-finishes, use Tenyu Tools HSS blades with brazed carbide or diamond tips.

Circular saws are available in two designs.

- Direct drive where the blade is mounted directly on the arbor and 90 degrees to the motor.

- Worn drive where the saw blade is gear-driven ahead of its motor.

There are three types of blades to match your needs- ripping blade, crosscut blade, and combination blade.

- The ripping blade cuts your material lengthwise with or along the grain.

- Crosscut blade cuts across the grain.

- Combination blades deliver ripping and crosscutting performance.

This industrial wood cutter operates at high speed.

It is powered by electricity, a hydraulic motor, or a gasoline engine.

It is portable and easy to operate.

- Industrial Wood Miter Saw

Another popular industrial wood cutter is the miter saw.

It is known for delivering quick, accurate miters and crosscuts.

This power tool is often called a chop saw or drop saw.

Its ergonomic design creates precise angled cuts with distinct miter joints.

It cuts the material by pulling the spinning circular blade down to the material.

To get an excellent result, you need to do a short, controlled pull.

The distinguishing characteristic of a miter saw is its miter index.

The miter index allows changing the blade relative to the fence.

It is usually made of carbon steel with a special coating.

This industrial wood cutter has a blade size configuration of 8, 10, and 12 inches.

The larger the blade’s diameter, the longer cuts it delivers.

There are several kinds of industrial miter saws:

- Standard/Power meter saw

This industrial wood cutter is designed to make straight cuts at a wide range of angles.

- Compound miter saw

A compound miter saw allows head and blade tilting at a variety of angles.

The pivoting motion gives excellent bevel cuts.

This industrial wood cutter will give you cuts for door frames, window casing, crown molding, and picture frames.

- Sliding compound miter saw

This type of miter saw lets you move the head back and forth the sliding rail.

The motion amplifies the length of the cuts.

It also allows locking of the rails to make a straight, pull down cut.

To maximize the sliding feature of this industrial wood cutter, pull the head forward first before turning it on.

Once on, simply push the blade back into the material.

- Dual compound miter saw

Another industrial wood cutter that is worth buying is the sliding compound miter saw.

This power saw allows you to rotate its head when angled on both the right and left sides.

Without repositioning the workpiece, you can achieve all available angles.

- LED/Laser miter saw

This industrial wood cutter is an advanced version of a miter saw.

It comes with a disc-shaped washer that easily attaches to the blade.

The laser illuminates the cutting line.

Some miter saws have LED feature that brings brighter illumination.

The laser guide feature is designed to produce more precise cutting.

- Jigsaw

A jigsaw is a perfect industrial wood cutter if you are working on thin sheet material.

This handheld power saw is not ideal for thicker pieces because of its short blade.

Investing in a jigsaw gives you a lot of benefits.

While providing cutting advantages, it also helps you design the wooden pieces.

The downward-pointing blade can create curved, serpentine, or straight cuts.

When you are into artsy designs and like irregular pieces, this industrial wood cutter is a great option.

It has a reciprocating, saber-like blade that produces intricate and elaborate designs.

It is easy to operate, lightweight, and generally quiet while in action.

The jigsaw allows an up and down or back and forth motion for more versatile cuts.

It cuts with utmost perfection with little to no wastage issue.

- Table Saw

The table saw is ideal for creating exact straight cuts.

This industrial wood cutter features circular rotating blades.

It looks like an upside-down circular saw.

The blade emerges upwards from the table or work surface.

It requires you to push the wood material into the blade.

You can customize or adjust the blade depth to match your cutting goals.

Table saws deliver cuts that are not easy to achieve with other types of saw.

It is great for producing numerous rip cuts or identical-sized pieces.

There are three types of table saws:

- Benchtop table saw

It is direct-drive, compact, lightweight, and portable.

The only downside is the noise that it creates during the process.

- Cabinet table saw

This is the heavy-duty type with a motor enclosed in the lower cabinet.

The blade of this industrial wood cutter is driven by a belt-and-pulley system.

It is perfect for all-purpose applications from ripping lumbers to cutting wood panels.

- Contractor table saw

It is the choice of building contractors who need quick cutting outputs on job sites.

This industrial wood cutter is also economical.

Table saw operation can be tricky and dangerous for beginners and untrained people.

You need to be properly trained and capable before using this industrial wood cutter.

- Band Saw

If you are looking for an industrial wood cutter that can rip rough stock, band saw got you covered.

It combines the power of the saber and circular saws.

This cutting tool features fixed teeth on the looped, flat steel band that goes around the pulleys.

There are two kinds of band saw- stationary and portable.

- A stationary band saw is the best option for safety-conscious manufacturers and builders.

This industrial wood cutter eliminates the danger of kickbacks.

It uses a band of continuous blades that spin around two or three wheels to deliver cuts.

This floor-standing saw usually has large pulleys above with a cutting table below.

The blades feature fine teeth, making them suitable for different materials.

They form part of the table, giving you an industrial wood cutter workshop to cut wood, plastics, pipes, and more.

It works efficiently without the usual irritating noise.

If you need thinner pieces, the stationary band can help you re-saw the boards.

- A portable band saw is the handheld version of the stationary band saw.

It can do most of the tasks that its big brother does.

It comes with a looped blade that revolves around the two wheels to make cuts.

This industrial wood cutter suits cutting smaller pieces of material.

It is mostly used by welders, metalworkers, and plumbers.

- Scroll Saw

This specialized industrial wood cutter is designed to help you make curved and intricate edges.

It is known to produce precise patterns, scrolls, and spiral lines.

The blade of the scroll saw can be attached to a band or be continuously oscillating.

You can fix it easily to a small work table to hold the material in place as you cut.

- Radial Arm Saw

The radial arm is a type of industrial wood cutter with a circular rotating blade.

The blade is attached to a raised arm over the table.

You can easily move the arm at different angles to achieve miter cut, straight cut, and compound cut.

- Reciprocating Saw

This small saw offers excellent performance and versatility.

The reciprocating saw is a versatile and portable industrial wood cutter.

It works by powering the tiny blade to make a back and forth motion while cutting the material.

It is also very useful for cutting beneath wood joints or walls.

The blade of this industrial wood cutter can cut both the wood and nail.

It is an invaluable tool during your demolition work.

You can choose to buy the corded or cordless option to suit your needs.

- Flooring Saw

This specialized industrial wood cutter is designed to cut hardwood, bamboo, and laminate flooring.

It can make straight cuts and miter cuts for flooring installation.

- Chain Saw

This heavy-duty industrial wood cutter is one of the vital tools of professional loggers.

It is powered by a dynamic cutting chain and a small gas engine.

What are the Other Industrial Wood Cutters?

- Lathe

A lathe is a machine that cuts wood blocks into cylindrical objects.

This industrial wood cutter uses a turning process to make various wood shapes and sizes.

It is a versatile woodworking tool that allows easy attachment of other tools.

It provides an ideal surface finish, gives shape to wood boards, and creates decorative pieces.

Investing in a quality lathe involves a great amount of money, but it is worth the price you pay.

This industrial wood cutter is a major purchase that gives a lot of benefits.

- Router

The router is used to cut wood and create cuts into the wood surface.

Technically, this industrial wood cutter is utilized to hollow out a section in the wood material.

This tool is also used to round off the edges of wood and make grooves or slots in the material.

It can handle different attachments or accessories to produce various types of joints.

- Hydraulic log splitter

It is a mechanical machine that cuts wood efficiently.

This industrial wood cutter has all the features that manual tools do not possess.

It delivers multiple purposes of cutting and shaping your wood materials.

What are the Precautionary Measures When Using Industrial Wood Cutters?

To avoid safety and health hazards in the workplace, the woodworking industry follows standard protocols.

It is necessary to keep a safe work environment.

Workers should maintain safe work habits and obey the rules at all times.

You also need to keep vigilant supervision of the overall operation.

All the woodcutting tools must be used, stored, and cleaned properly.

Do You Like to Start a Business of Industrial Wood Cutter?

If you are interested in becoming a distributor or wholesaler of industrial wood cutter and accessories, Tenyu Tools is the name to trust.

It is the leading manufacturer-supplier of high-quality products that are used in manufacturing, construction, and production applications.

Enjoy great deals and advantages when you do business with Tenyu Tools.

They have importers and distributors in North America, Eastern Europe, Northern Europe, and other parts of the world.

What are you waiting for Industrial Wood Cutter?

Contact Tenyu Tools now and inquire about their business packages.

We also hope that this ultimate guide helps you become more familiar with the industrial wood cutter.