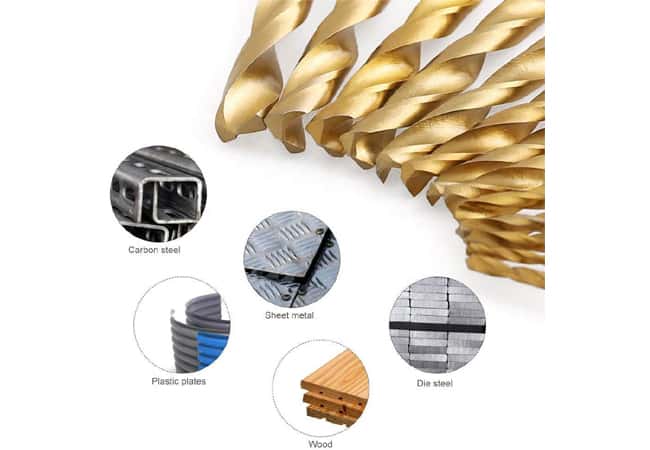

HSS Straight Shank Twist Drills are Named After Twists Because Their Chip Flutes are Spiral

The twist drill bits material is generally high-speed tool steel or cemented carbide

It is widely used in automobile manufacturing, mold, machinery, logistics, and other departments

Let’s Learn About Manual Sharpening Techniques for Twist Drills Bits

The sharpening head should be level with the wheel surface

1. Before Grinding a Straight Shank Twist Drill Bits

First place the main cutting edge of the twist drill bits and the grinding wheel surface on a horizontal surface, thereby ensuring that the entire cutting edge is ground when the cutting edge contacts the grinding wheel surface

This is the di step of the relative position of the drill and the grinding wheel. After the position is set, slowly move to the surface of the grinding wheel

2. This Refers to the Positional Relationship Between the Axis of the Twist Drill Bits and the Surface of the Grinding Wheel

It is sufficient to take 60 °, this angle is generally more accurate

Here we should pay attention to the relative horizontal position and angular position of the drill before sharpening. Both must be taken into consideration

Do not neglect the angle for the sake of flattening the edge, or ignore the flat edge for the sake of angle

3. Grind Back From the Edge

After the cutting edge contacts the grinding wheel, it must be ground back from the main cutting edge

The cutting edge of the twist drill bits first contacts the grinding wheel, and then the entire flank surface is slowly ground down

4. When Cutting the Bit, You Can Touch the Grinding Wheel Lightly

First perform a certain amount of sharpening, and pay attention to observe the uniformity of the spark, adjust the pressure of the hand in time, and pay attention to the cooling of the bit

Anneal to the cutting edge. When the cutting edge temperature is found to be high, the drill should be cooled in time

5. This is a Standard Drill Grinding Operation

The main cutting edge should swing up and down on the grinding wheel, that is, the hand holding the front of the drill should swing the drill up and down on the grinding wheel surface evenly

But the hand holding the handle cannot swing, and the rear handle must be prevented from tilting upward, that is, the tail of the drill cannot be raised above the horizontal centerline of the grinding wheel, otherwise the cutting edge will be dull and cannot be cut

6. This is a Key Step

The drill is ground well or bad, and the technique is very important

When the grinding is about the same, start from the cutting edge, and then gently press it at the rear corner to make the back of the cutting edge smoother

7. Make Sure that the Cutting Edge of the Twist Drill Bits is Aligned with the Radius, and Slowly Eepair Both Sides Symmetrically

After the cutting edge is ground, the other cutting edge must be ground, and the cutting edge must be in the middle of the vertical and horizontal sides of the drill

The cutting edges on both sides must be symmetrical. It is suitable for rake angle grinding, the center of the tip is symmetrical, and the two edges are symmetrical

When drilling, the drill chip is light, no vibration, and will not expand

8. After the Two Edges of the Drill are Ground

There is a plane at the tip of the two edges, which affects the center positioning of the drill

You need to chamfer behind the edge and try to sharpen the plane of the edge

9. The Method is to Erect the Twist Drill Bits, Align it with the Corner of the Grinding Wheel, and Pour a Small Groove at the Root Behind the Blade Against the Blade Tip

This is also an important point for bit centering and light cutting. Note that when chamfering the cutting edge, do not grind it to the main cutting edge

This will increase the rake angle of the main cutting edge, which will directly affect the drilling

Mastering the manual sharpening method of a straight-hand twist drill bits is an important job

Accumulates experience in actual operation

Know more about the drill bits and saw blades, click here!