An aluminum door and window manufacturing plant produced burrs shortly after cutting aluminum saw blade.

So what caused it?

- The model and parameters of the saw blade do not match the machine tool and material

- The accuracy of the machine tool is not high

- The operation of workers is not standardized

- The quality of the material

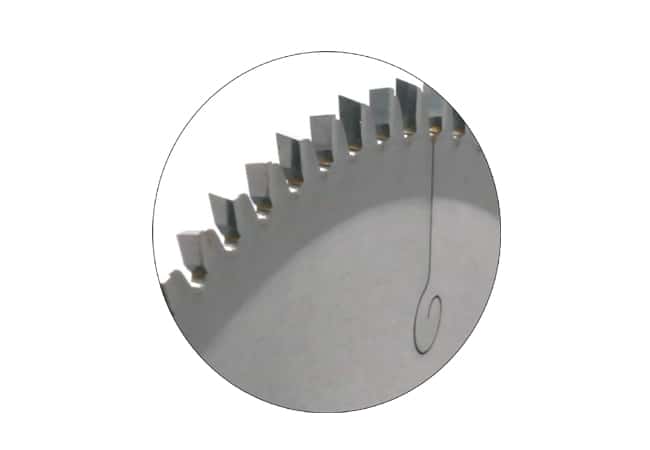

- The heat treatment of the substrate

- The quality and angle of the cutter head

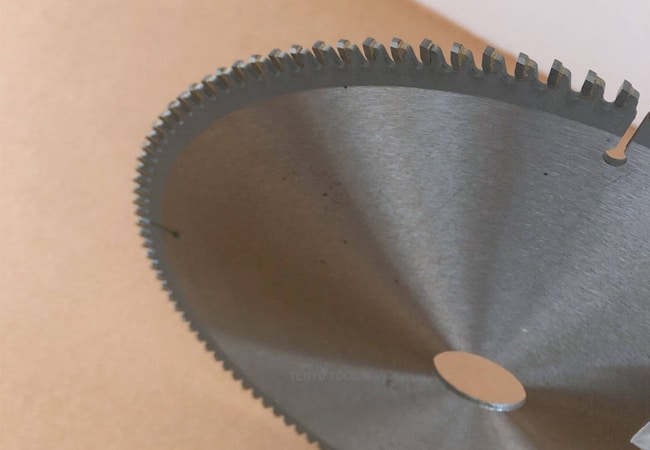

- Choose the blade designed for cut aluminum

- Static and dynamic accuracy and performance

- The performance of the material

Under the normal conditions of machine tools, saw blades and materials, it is very important to choose reasonable cutting parameters

A little tips

- Please be sure wear safety glasses or a face shield if you need to cut any type of metal

- Thicker materials require fewer teeth, and thinner materials require more teeth

- Please lubricate the saw blade, it can give more protection, such as the saw blade wax stick

- Do not wear gloves or precious item when using the saw blade