Diamond blades might seem like magic, but they’re really just the product of some clever engineering and a lot of attention to detail. In this article, I’ll break down how they’re made and share everything I’ve learned about these incredible tools. We’ll dive deep into every aspect of diamond blades, from their types and applications to their advantages and care tips. By the end of this guide, you’ll have an extensive understanding of diamond blades, including insights that can help you choose the right one for your projects.

Diamond blades are made by bonding synthetic diamond crystals to a steel core, using high-temperature and high-pressure techniques. These blades are designed for cutting through hard materials like concrete, tile, and stone, with the diamonds acting as abrasives that grind through tough surfaces. The manufacturing process ensures that each blade can handle intense heat and pressure, making them efficient and long-lasting for professional use.

Want to know more about what makes these blades so special? Let’s dig a bit deeper.

Types of Diamond Blades?

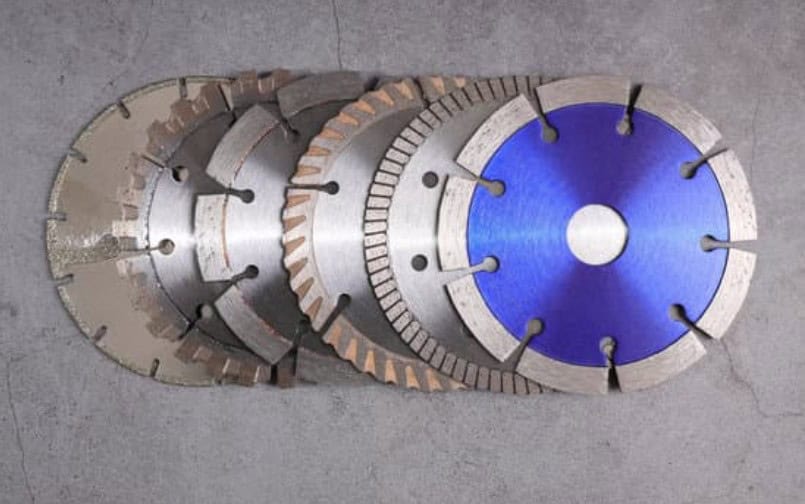

There’s no one-size-fits-all when it comes to diamond blades. Each type is designed with a specific purpose in mind, depending on the material you want to cut and the finish you’re looking for.

Diamond blades come in different types, including segmented, continuous rim, and turbo blades. Segmented blades are ideal for dry cutting, thanks to the cooling gaps between segments, while continuous rim blades are best for wet cutting and delivering a smooth finish. Turbo blades combine speed and precision, making them a versatile option for both wet and dry applications.

Segmented Blades: Strength in Gaps

Segmented diamond blades have distinct sections, or segments, separated by gaps. These gaps help cool the blade while cutting, making them ideal for dry cutting applications1. They work great for rough materials like concrete and brick, where speed is more important than a perfectly smooth edge.

Segmented blades are often used for construction and demolition purposes where precision isn’t as critical. The gaps between segments allow air to flow through, reducing friction and keeping the blade cool. This means you can cut for longer periods without needing to stop as often to cool down the blade. Additionally, these gaps make it easier to remove debris from the cut, which helps maintain cutting speed and efficiency.

These blades are also designed to handle a lot of stress, making them ideal for heavy-duty applications. If you need to cut through asphalt, concrete, or bricks, a segmented blade is your best bet. However, they are not suitable for materials that require a smooth finish, as the segmented design can leave rough edges.

Continuous Rim Blades: Smooth Sailing

Continuous rim blades, on the other hand, are all about precision. They’re designed with a solid rim and are typically used for wet cutting. If you need a clean cut on materials like ceramic tiles, this is the blade for you. The water helps keep everything cool, which also helps to prolong the life of the blade.

These blades are particularly popular among tile installers and masons who need a smooth, chip-free cut. The continuous rim design allows for an uninterrupted cutting surface, which provides a cleaner finish compared to segmented blades. Water is used not only to cool the blade but also to reduce dust, which makes the working environment safer and more pleasant.

Continuous rim blades are most effective when used with materials that are prone to chipping or cracking, such as porcelain, marble, and glass. The water acts as a lubricant, helping the blade glide through the material without causing damage. This is why continuous rim blades are a favorite for finishing work where the quality of the cut is more important than speed.

Turbo Blades: The Best of Both Worlds

Turbo blades are a bit of a hybrid. They’ve got a solid rim with tiny serrations, allowing for faster cutting without sacrificing too much in terms of finish quality. They can be used for both wet and dry applications, making them versatile and popular among professionals.

Turbo blades are designed to combine the speed of segmented blades with the smooth cutting capability of continuous rim blades. The serrated edge helps move material away from the cutting path, which allows for faster cuts. This makes turbo blades ideal for a variety of materials, including concrete, brick, and even some types of stone.

One of the biggest advantages of turbo blades is their versatility. Whether you need to cut through hard concrete or softer tile, a turbo blade can get the job done. They’re also a good choice for projects that require both speed and a reasonably clean finish. While they may not provide as smooth a cut as a continuous rim blade, they’re often the preferred choice for general-purpose cutting because of their adaptability.

| Type | Best For | Cutting Style | Cooling Method |

|---|---|---|---|

| Segmented | Concrete, Brick | Fast, Rough | Air (Dry) |

| Continuous Rim | Ceramic Tile | Smooth | Water (Wet) |

| Turbo | General Use | Balanced | Wet or Dry |

How Much Diamond Content is in Diamond Blades?

You might be wondering, how much actual diamond goes into these blades? Well, the answer might surprise you—it’s not as much as you think.

Diamond blades contain a small amount of synthetic diamond particles that are bonded to the blade’s edge. The concentration of diamonds can vary depending on the type and purpose of the blade, but typically, only a thin layer of diamonds is used. This layer is strategically placed to maximize cutting efficiency while keeping costs reasonable.

The synthetic diamonds used in these blades are man-made, which helps keep the cost down while still providing the cutting power needed to get through tough materials. The diamonds are mixed with a metal bond, which helps hold them in place and distribute the cutting force evenly across the blade. This bond is designed to wear away gradually, exposing new diamonds as the blade is used, which helps maintain its cutting ability over time.

The amount of diamond content2 in a blade can vary based on the intended use. For example, blades designed for cutting extremely hard materials may have a higher concentration of diamonds to ensure they can handle the stress. On the other hand, blades used for softer materials may have a lower concentration, as they don’t need as much cutting power. The key is to find the right balance between cost and performance for the specific job at hand.

The Advantages of Using Diamond-Tipped Saw Blades?

Why go for diamond blades when there are so many other options out there? It turns out, these blades have some serious advantages.

Diamond-tipped saw blades offer unmatched durability and cutting efficiency. They can handle extremely tough materials like stone and concrete with ease, providing smooth and precise cuts. The diamond particles also extend the life of the blade, making it a cost-effective choice for professionals who need reliability and performance in their tools.

One of the biggest advantages of diamond blades is their ability to maintain cutting power over time. Unlike traditional steel blades, which can dull quickly when used on hard materials, diamond blades are designed to stay sharp for much longer. This means fewer blade changes, which not only saves time but also reduces costs in the long run.

Another advantage is the precision they offer. The diamond particles act as abrasives, grinding through the material rather than tearing it apart. This results in cleaner cuts3 with less risk of chipping or cracking, which is especially important when working with delicate materials like tile or glass. The ability to make precise cuts also means less waste, as there’s less chance of damaging the material during the cutting process.

Diamond blades are also highly versatile. Whether you’re cutting concrete, tile, asphalt, or even metal, there’s a diamond blade designed for the job. This versatility makes them a valuable tool for professionals in a wide range of industries, from construction and demolition to masonry and tile installation. The ability to use the same blade for multiple applications can help simplify tool management and reduce the need for specialized equipment.

In addition to their cutting power and precision, diamond blades are also designed to withstand the heat generated during cutting. The combination of synthetic diamonds and metal bonds helps dissipate heat, reducing the risk of the blade warping or breaking under pressure. This makes them a safer option for heavy-duty cutting, as there’s less chance of the blade failing during use.

Everything You Need To Know About Diamond Blades?

Whether you’re a professional or a DIY enthusiast, understanding diamond blades can make a big difference in your work. But there’s a lot to know!

Diamond blades are designed for cutting through extremely tough materials by using diamond particles as abrasives. Depending on the type of blade, they can be used for dry or wet cutting, each having its own advantages. Proper maintenance and the correct application are crucial to extend the life of the blade and ensure safety during use.

Let’s break it down so you can get the most out of your diamond blade.

Maintenance Tips for Diamond Blades

Maintaining your diamond blade is key to getting the most bang for your buck. Here are a few pointers:

- Clean Regularly: After each use, make sure to clean the blade. Debris can affect the cutting performance and reduce the lifespan of the blade.

- Avoid Overheating: Overheating is a major cause of blade wear. If you’re dry cutting, make sure to take breaks to let the blade cool down.

- Use the Right Blade for the Job: Each diamond blade is made for a specific type of material. Using the wrong blade can not only lead to poor results but also damage the blade.

Safety First

Working with diamond blades means dealing with fast rotation and tough materials. Always wear appropriate safety gear, such as gloves4, goggles, and protective clothing. When using wet-cutting methods, be mindful of the electric tools you’re using to avoid accidents.

Using a diamond blade can be highly rewarding, especially when you see just how clean and precise your cuts are. But with great power comes great responsibility. Always follow safety protocols to protect yourself and others around you.

Choosing the Right Blade for Your Project

Choosing the right diamond blade is crucial for achieving the best results. Here are some factors to consider:

- Material Type: What are you cutting? Concrete, tile, stone, or metal? Each material requires a specific type of blade.

- Wet or Dry Cutting: Some blades are designed specifically for wet cutting, while others can be used dry. Wet cutting helps reduce dust and keeps the blade cool, which is ideal for long cuts or delicate materials.

- Cut Quality: Do you need a rough cut or a smooth finish? For rough cuts on tough materials, a segmented blade is ideal. For a smooth, chip-free finish, a continuous rim blade is the way to go.

| Factor | Options | Considerations |

|---|---|---|

| Material Type | Concrete, Tile, Metal | Different blades for different materials |

| Cutting Method | Wet, Dry | Wet for cooling and dust control, Dry for convenience |

| Cut Quality | Rough, Smooth | Segmented for rough, Continuous Rim for smooth |

Conclusion

Diamond blades are incredible tools, designed for tough jobs and lasting performance. With the right type and proper care, they can make your toughest cutting tasks feel a whole lot easier. Choosing the right blade, maintaining it properly, and using it safely are key to getting the most out of your diamond blade.

-

Segmented blades excel in dry-cutting scenarios, addressing the needs of users working in environments without water cooling. ↩

-

To understand how varying diamond concentrations optimize blade performance for different materials. ↩

-

Explore more about the importance and techniques of achieving precise, high-quality cuts. ↩

-

Safety is critical in this context, glove types support informed decision-making. ↩