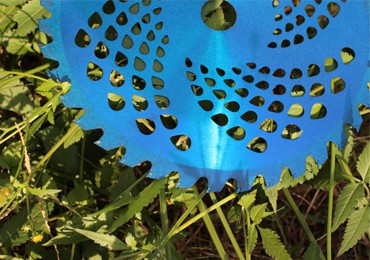

Grass Cutting Blade

- Grass Cutting Blade Durable and Teeth Sharp & Hard Steel.

- Weed Eater Grass Garden Mower Trimmer Tool for Grass Cutting Blade.

- Grass cutting blades are designed to provide a high mowing capacity in difficult conditions, such as matted and dry grass, ferns and reeds.

- The blades are made of high-quality materials that resist wear and tear, and they are sharpened to provide a clean cut. The easy start-up design makes it easy for women to use the brush cutter, and the safety features make it safe for everyone.

- With 15+ years of experience in OEM and export, Tenyu Tools is your trusted source for high-quality and affordable brush cutters.

Tenyu Grass Cutting Blade Video

Why Tenyu

Grass Cutting Blade

- Tenyu Tools Co., Ltd. The Best Grass Cutting Blade Manufacturer

- Grass Cutting Blade choose China Tenyu saw blades, you will find high-quality grass cutting blade.

- It is important to cut the grass regular. You can cut the grass fast and smooth with grass cutting blade.

- You can get premium grass cutting blades for a very low price here at Tenyu Tools

- Your trims would be easy, fast, and accurate, thanks to the carbide-tipped technology

- You can cut and trim weeds, grass, leaves, vines, etc.

- The blades of your grass cutters are extremely durable and long-lasting

- You can easily and conveniently sharpen the blades of your grass cutters

- You can order customized grass cutting blades, depending on what you need

- All of your orders and products will arrive in 2 to 3 weeks!

- You can have your orders replaced if there are problems with quality – we got you!

3 Tooth Carbon Steel Brush Cutter Weed Eater Grass Blade for Weeds and Shrubs Cutting

6 Cutter six-Leaf Garden Lawn Mower Trimmer Head Grass Weed Eater Brush Cutter Saw Blade

10inch 255mm 40T Weed Eater Brush Cutter Grass Cutting Blade for Thick Weeds and Brambles

250mm 40Teeth Grass 4 Cutter Brush Blade for Faster Cutting Grass Small Trees Wheat Prevent the Grass from Getting Stuck

250mm 40Teeth Grass Cutter Brush Blade for Faster Cutting Grass Small Trees Wheat Prevent the Grass from Getting Stuck

Brush Cutter Blade 2 Tooth Manganese Steel Lawn Mower Grass Cutter Blade Accessories

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

Jumply scaffolding has rich experience and advanced automatic equipment, which can provide scaffolding customized production to meet different needs.

Jumply represent the safety and qualified scaffolding via our construction projects.

Feel the Quality via our products. We improve them always.

Business Advantages of Choosing Tenyu Tools’ Grass Cutting Blade

Tenyu Tools Co., Ltd. is the top and the most sought after grass cutting blade manufacturer in China.

Tenyu Tools Co., Ltd. is a one-stop-shop power tool and accessories company thousands of businesses have trusted over the past decade.

We are equipped with the best and the most experienced experts and innovators, who can help and assist you with the grass cutting blades you need!

Tenyu Tools holds several certifications – from ISO and SGS to conformance licenses and certificates, CE certificates, and many more!

You won’t ever have to trim your lawn manually if you have our grass cutting blades!

- Our grass cutters have all been made and formed via heat treatment, ensuring durability

- You can fully customize the features and the physicality of your grass cutting blade

- You can save money because our grass cutting blades are all-around; use them for many different types of plantation

- Unlike the products of other manufacturers, Tenyu Tools’ grass cutting blade can be sharpened more than 20 times!

We’re able to deliver the serious quality of grass cutting blades; quality in terms of the blade quality, packaging, manufacturing procedure – and even our customer experience.

Tenyu Tools can help you whether you need a 40T weed eater, a 4T carbon steel wee eater, a TCT grass cutting blade – or even a customized grass cutting blade!

But what are the features and the functionalities that separate our grass cutters to the grass cutters of our competitors?

Features and Advantages of Tenyu Tools’ Grass Cutting Blade

What are the Applications of Our Grass Cutting Blades?

Since they’re grass cutter blades, are they limited to cutting the grass only? No, they’re not!

Inspection Angle for Grass Cutting Blade

Inspection Level for Grass Cutting Blade

Drilling Inner Hole for Grass Cutting Blade

Grass Cutting Blade of Body Material

Welding Machine for Grass Cutting Blade

Welding Teeths for Grass Cutting Blade

Inspection Teeth for Grass Cutting Blade

Polish Teeth for Grass Cutting Blade

Polish Machine for Grass Cutting Blade

Polish Machine for Grass Cutting Blade

Plastic Pipe Machine for Grass Cutting Blade

Workshop for Clean Grass Cutting Blade

Workshop for Grass Cutting Blade

Inspection Machine for Grass Cutting Blade

Quality Inspection Test for Grass Cutting Blade

You can mount it on a handheld cutter, a mower, and other types of tools and equipment!

As a matter of fact, you can also cut and trim small trees, weeds, roots, and other kinds and types of foliage.

If a certain area is not reached by a lawnmower, using Tenyu Tools’ grass cutting blades can help you reach and cut it swiftly and cleanly!

You can consider us here at Tenyu Tools Co., Ltd. as your business partner whether you plan on being a distributor, a retailer – or if you need bulk grass cutters for your business!

You can cut and trim many different kinds of plantation and foliage using our grass cutters

Work With the Best Today!

Contact us now and get a huge discount for the grass cutting blades you need! We can also deliver a free quotation for you and your team for the products you require!

Grass Cutting Blade

Grass Cutting Blade

Grass Cutting Blade

Grass Cutting Blade – The Comprehensive FAQ Guide

Lawn mowers aren’t the only tools you can use to cut or trim grass – in fact, there are far more effective tools that have better grass cutting blades available in the market.

If you’re new to power tools and accessories, don’t worry! We’re here to help you with it!

In this guide, we’ll be detailing everything you need to know about grass cutting blades. We’ll discuss what it is, what other things you can do with it – and ultimately, where you can find the best ones to grab your customers’ attention

From its term alone, they’re blades you can use to cut grass, weeds, and other kinds of foliage and vegetation.

What is a Grass Cutting Blade?

An image of what a grass cutting blade is

More often than not, they’re composites are strong and sturdy metals. Some grass cutting blade manufacturers even add a bit of touch to its tips and teeth.

Can I Make a Grass Cutter Blade at Home?

You can make the machine, yes – but when it comes to the blade itself? – It’s going to be difficult, but you can.

DIY grass cutting blade you can make at home

In most cases, DIY grass cutting blades would be literal blades from cutters, big razors, shaving blades etc.

The most common would be shaving blades, but you’ll only be able to create a small grass cutter.

Grass Cutter Blade Material

Manufacturers utilize varying materials and resources in producing their grass cutting blades.

Some use carbon steel, while most grass cutting blade supplier use high-quality steel for the body (usually 65 MN steel), and a tip of carbide at the teeth for sharper, better, and neater cutting.

What are the Best Grass Cutting Blades?

Tenyu Tools’ brush grass cutters, one of the best in the market today

This is relative – some products might have worked for a few people, not the majority, but could still get a high rating.

What are the Best Grass Cutting Blades

To be fair, we’ve tracked down the market’s top-selling, and most sought after grass cutting blades.

We based it on popularity, effectiveness, and price.

The top grass cutting blades that are in the market include:

- Ego Power + Lawn Mower Blade

- Renegade Blade

- Tenyu Tools Co., Ltd.

- Toro Mower Blade

- Gator Fusion Mulching Blades

- And Others

When you decide to choose and purchase any of these, you’ll surely never have a problem!

Choosing Tenyu Tools’ grass cutting blades, though, will give you the best results – for what reason? – We’ll get to that later.

Brush Cutter vs. Grass Trimmer: What’s the Difference?

Many people still can’t understand the differences between a brush cutter and a grass trimmer.

Image of a grass trimmer being used to thin already thick grass

While it seems so obvious, a lot of people still get dumbfounded by what the differences are. Fret not! Here are a couple of things you can remember to successfully differentiate the two.

Both of them are machines you can use to beautify your lawn, your patio, your garden, or your backyard. However, there are some distinctive factors between them:

Grass Trimmers

From the term alone, grass trimmers are machines you can use to trim the lawn or the vegetation. For instance, if you see that your weeds are growing thicker, it’ll still be safe to use a grass trimmer.

You can safely use grass trimmers for: dead grass, thin weeds, and thin lawn that mowers don’t reach.

Different Types of Brush Cutter Blades

If we were to look at it generally, we can classify four (4) different types of brush and grass cutting blades.

An example of a grass cutting blade (knife grass and brush cutter)

We have the Knife, Smasher, Mulching, and Chisel.

Knife Grass Cutters

Akin to what it’s called, these are blades that have sharpened edges. That’s what you’ll use to cut and slice through grass and plants, and they’re usually made from high-quality steel.

Smasher Grass Cutters

Unlike knife blades, the smasher type of grass cutting blades has no sharp edges.

What they use to cut would be the blade itself, and it will vary and depend according to the thickness of it.

They function and work similar to a flail where the blades are tossed – they smash through grass and other types of vegetation.

Mulching Grass Cutters

Mulching grass cutters are the traditional tools used to cut or slice through grass.

They’ve been designed to “mulch” or to cut vegetation finer and more effectively. Usually, they’re thin and have an angled edge, which is used for cutting.

Chisel Grass Cutters

Last but most definitely not the least are the chisel grass cutting blades.

These are the blades that are most commonly used with a wide array of power tools. They come in a circular saw blade kind of shape with teeth sharpened and enhance.

They’re known to be more efficient in cutting and trimming, and you can also utilize them to cut trough vegetation that has thin-to-moderate pieces of wood.

These are the different grass cutting blades you can decide to choose from in the market. You’d have to select depending on the action and the type of result you want to achieve.

Where Can You Apply Grass Cutting Blades?

One way of successfully advertising your grass cutters is through showcasing what applications they can have for it.

You can use it to work on both residential and commercial properties

For Tenyu Tools’ grass cutting blades, you can use it on a wide range of applications, namely:

- Home use (garden, porch, and backyard)

- Trimming of grass, shrubs, and trees

- Commercial agricultural and farming use

- Farmland use

- Residential and commercial landscapes

- Trimming of vegetation in forests

- And so on!

We have designed all our grass cutting blades to be versatile; that’s what put us atop the manufacturing ladder.

Our Grass Cutting Blades Durable?

Yes, grass cutters are durable and strong. Most of it is because of the fact that it’s heat-treated, but there are some parts that dictate it’s because of the type and the quality of steel used.

An example of a homemade grass cutting blade – it’s dull and corroded

The usual manufacturing procedures grass cutting blades undergo include:

- Quenching

- Firebacking

- Face hardening

- Cooling

- Re-enhancing

Can You Purchase Grass Cutting Blades Wholesale?

Yes, there are manufacturers that offer wholesale sets of grass cutting blades.

In fact, purchasing directly from a manufacturer often requires a “minimum order quantity” or an MoQ.

This is, of course, for the shipping and the delivery to be worth the price and effort.

How are Grass Cutting Blades Delivered and Ordered?

When you have a manufacturer in mind, the next best thing to do is to figure out the number of blades you need.

Cargoes and orders are shipped in bulk or in wholesale

Then, you just have to follow the same process of how you would order:

- Contact and tell the manufacturer that you’re going to order

- Arrange all the papers and documents needed from your end

- The manufacturer, in their part, would be preparing documentation, too

- After all the products have been assessed and quality-checked, they’ll pack it

- Then next is the delivery of the package

How Much Does a Blade For a Grass Cutter Cost?

The typical price for a grass cutting blade would depend on many factors; these factors include, but are not limited to:

- Type of Grass Cutting Blade

- Manufacturer of the Blade

- Function and Features of the Blade

- Compatibility of the Blade

- Material Used to Produce the Blade

- And So On

Generally, the price for grass cutting blades cost somewhere around $.50 to $3 per piece – and that is if you purchase them in bulk.

Individually, though, they can cost anywhere between $5 and $15 if you’re going for their retail price.

The best thing to do to get the most accurate rates is to ask and inquire to the manufacturer of your choice about it. They can send you a free quotation or a free estimate for it!

Can I Order Custom Grass Cutting Blades?

A lot of grass cutter manufacturers have this as their specialty – this is one of the factors that make them stand out from other grass cutting blade suppliers.

Example of a custom-made grass and brush cutting blade

In creating a custom order, manufacturers would ask you for the following:

- Sketch or design of the blade

- Materials you ought to use for the blade

- Procedure of how you want it done

By knowing these information, a manufacturer would be able to grasp on the type and the kind of blade you’re looking to get.

What Product Specifications Should You Note in Purchasing Grass Cutting Blades?

In choosing a particular grass cutter, you need to take note of the following specifications:

Usage

Usage is the specific category that will give you knowledge on how you can use it. This is important because choosing an incorrect blade can result to a lot of problems, such as:

- Blade damage or dullness

- Soil breakage

- Low-quality results

- And many more!

For instance, usage of grass cutters could be for grass, lawns, bushes, brushes, etc.

Blade Outer Diameter

This refers to the total size of the blade from outside its diameter.

If you’re not sure of what diameter of the blade you’re eyeing on is, you can easily look at its label. This is relevant because you need to know if what you’ll buy fits your power tool or machine.

Body Thickness

Usually determined in millimeters (mm), this refers to the size of the blade’s thickness.

The most common ones range between 1 to 1.6 mm.

Is the blade thick enough for my tool? Or would it fit? – Those are the questions you should be asking when purchasing.

Kerf

Kerf is easily defined as the width and the measurement of the material removed by the process.

The best example would be a kerf that is about 2 mm; meaning the width and the specific thickness that your grass cutting blade would produce.

Hole Diameter

You’re able to mount or attach your grass cutters to your power tools because of its hole or boring hole.

The hole diameter is the measurement of the boring hole or the “center hole” of your blade; it must fit the power tool you’ll use.

Teeth Count

Last but most definitely not the least is the teeth count. It’s pretty straightforward – the teeth count is the number of teeth of a grass cutting blade.

Selecting a blade with more teeth can work cleaner, neater, and smoother. You’d want a grass cutting blade with more teeth if you are going to work on landscapes, gardens, commercial vegetation, etc.

Those with fewer teeth, on the other hand, will be able to cut faster.

Which Grass Cutting Blade Supplier Should You Trust?

For more than 15 years, Tenyu Tools Co., Ltd. has been China’s top grass cutting blade manufacturer.

Tenyu Tools, the best grass cutting blade supplier in China

We’ve delivered countless grass and brush cutters to our clients worldwide. You can bank and count on us too!

Most, if not all of our grass and brush-cutting blades have average-sized bores! You wouldn’t worry about it not fitting on your machine!

Whether you need a 6-teeth steel grass trimmer, a carbide-tipped brush cutter, and even a customized grass cutting blade – we got you!

You will never have any regrets in choosing us here at Tenyu Tools Co., Ltd. for the grass cutters you need!

Why Work With Tenyu Tools Co., Ltd. for Your Grass Cutting Blade?

Tenyu Tools Co., Ltd. has been the go-to manufacturer of suppliers and manufacturing companies in Asia, as well as in North and South America.

Their continued trust is due to the lack of leniency and mistakes we have.

- We are a company with CE, SGS, and ISO licenses and certifications

- We’ve developed and fully enhanced our manufacturing processes

- We use the equipment we’ve made and manufactured

- Our packaging is completely sealed and protected – and is shipped via our trusted shipping companies and couriers

Never work with the wrong brush-cutting blade manufacturer ever again! Choose Tenyu Tools Co., Ltd. and get the best and the highest quality of grass cutters for the best and the most competitive rates available!

Contact us and get a free estimate of the products you need! Our MoQ is only at 100 pcs., we still reserve your right not to over-purchase!

More Details of Grass Cutting Blade :

You can learn more about Grass Cutting Blade from our article to know the most in-depth and also total info, But you can select the most effective Brush Cutter Blade, Grass Trimmer Blades to push your market.

Our company has been pursuing to provide customers with the best 4 sorts of brush cutter blades; grass cutting knife, Chisel, Smasher, and also Mulching.

Please read this article carefully, you will be able to learn more about Taoist temples, brush cutter blades,s and more product knowledge. Our copywriting will help you make better choices And can help you open your wholesale market business faster.

Due to the fact that it is made of one component as well as marked from steel plate to enhance manufacturing rate, High benefits; low-cost. Usually proficient at cutting soft products, such as lawn as well as marine plants. Yet this mainly relies on the style of the grass cutter blade manufacture. Relying on the top quality of the steel, Improved hardness.

Grass Cutting Knife

They are one of the most generally made use of steel fragments as well as are typically utilized brush cutter blades with steel products. There are some kinds, however, what they share is that they are normally constructed from slim steel sheet lasers or forms. Their form differs from seeing a circle, with loads of knife-shaped teeth. A celebrity cutter with one or 4 reducing blades, however, the low-cost china lawn trimmer blades offered over typically have a selection of uses, from 2 oblong to forty (such as circular saw blades).

Advantages: Cheap, due to the fact that it is made from one component as well as marked from steel plate to enhance manufacturing rate. Usually proficient at reducing soft products, such as lawn and also marine plants. Yet this greatly depends upon the layout of the blade. Relying on the layout as well as the top quality of the steel, several fines can generally be taken.

Disadvantages: As the pointer of the grass cutter blade comes to be blunt, the effectiveness will certainly lower swiftly. Due to the fact that the grass cutter blade turns so quickly that just the pointer of the grass cutter blade can make any kind of cut, this is. The reducing side of the blade actually just does any type of cutting, when the brush cutter blade of the head is quickly turning back and forth. As a deal with a blade, there is not a problem. When you struck a concealed rock or steel things as well as obtain a really solid influence, the idea of the blade will certainly flex or chip, relying on the kind of blade as well as the top quality of the steel. This is why a few of the 3 blades of the 4 side blades have actually inclined cutting sides. It is not to boost reducing effectiveness, however, to make the blade a lot more immune to damage for factors of duty.

Cutting Ability

Currently, if you can picture the head of your reducing equipment moving back and forth, the rate of the swing will certainly figure out just how much the blade is revealed to the brand-new lawn. The swing is so sluggish that just the suggestion of the blade can reduce. The swing is extremely rapid and also much more blades will certainly reduce the yard. Currently, think about a rectangle-shaped blade with 2 reducing sides, that is, revolving at 100 changes per 2nd, which indicates that the reducing sides pass the exact same factor 200 in one second. Expect you to turn the watering device sidewards by 1min 1 second. This implies that a brand-new product can in fact be reduced just 5mm from the blade. With a 4-blade blade, the external side cuts just 2.5 mm, while an 8-blade blade cuts just 1.2 mm.

This tiny blade has a tendency to end up being blunt promptly, so it ultimately shatters in the plant life, which indicates the blade promptly ends up being a ruining blade. The internal blade cuts just when this happens and also uncut harsh greenery jumps under the blade, or when cutting in upright movement. Blunt blades are among the primary factors individuals enter the practice of transforming the lawnmower to full speed and also tossing the blade right into larger plant life, a practice that is tough to damage when changed with saws or blades.

I have actually discovered that with these blades in the past, both – and also three-blade designs reduced the lengthiest, however that comes with an expense.

The variety of blades does have a large result on blade actions. The blade counts on the sharp cutting edge of the blade for reducing, however considering that the blade turns at 100 to 120 transformations per 2nd, just the outer side typically makes any type of cutting.

So as you can see, the blade does not in fact make any type of cut. Currently, 40 blades are made use of, each reducing just a portion of a millimeter. Hence, similar to a nylon string, just the outer pointer of the blade can in fact make any type of cutting.

There is additionally a propensity to drag the lawn to the facility as well as cover it around the equipment heads since these blades are star-shaped or rectangle-shaped. This implies that for celebrity blades, you require to maintain the lawn mower performing at full speed and also discard the longer lawn prior to it has a possibility to begin winding around the equipment head, even if this is not constantly effective for long, difficult turf.

This is why various blades are a much better fit for various kinds of plants, and also why numerous irrigation makers featured a variety of blades as a requirement. This is not an issue if there is just one planter in the location you are removing, however, it can end up being really excruciating if you need to maintain altering blades to fit various kinds of plants in a tiny location, as located on our building.

The performance of a multi-tip blade reduces with the rate of the loosened side of the pointer, yet at the same time, because of its rounded form, draws the turf beyond the blade and also is as a result much less most likely to create a lengthy yard to the equipment head.

Mulching Ability

In a similar way, star-shaped and also rectangle-shaped blade blades are best for covering when the blade passes up and down via the plants, as these blades supply the biggest blade location for the greenery.

Airecut Blade, made by a New Zealander, is without a doubt the very best cover Blade as well as might in fact be a much better fit as a cover Blade. Nonetheless, every little thing comes with a rate, and also with this blade, you wind up wearing a great deal of what you reduced since it tosses a great deal of the reducing product right into the air. Although the blade is solid, it is not undestroyable, as well as inadequate reducing routines established utilizing a blunt blade might trigger completion of the blade to break. Unlike flail blades, dealt with blades do not generate, as well as one way or another something will certainly generate when you struck something hard.

Rounder form, multi-blade, much shorter blade, virtually pointless for covering, and also very little extra can be claimed regarding covering.

Brush Cutter Blade

These kinds of blades have sharp teeth around the side of the blade as well as reduced by gouging or scuffing plant life. Every one of these blades is rounded as well as has different varieties of teeth around the sides. These teeth can be part of a blade as well as have actually a flexing countered for blade clearance, or have a chainsaw blade secured to a disc, or a real power saw blade secured in between 2 discs. Since the cost of these blades has actually gone down substantially over the years, currently most are tungsten suggestions.

Advantages: The cutting is much more reliable due to the fact that the reducing side lies on the surface, where it in fact reaches the product being reduced. Proficient at reducing tough products such as woody weeds and also woods.

Mistakes: Usually much more costly since they are much more intricate fit and also need added machining to flex, hone, or sign up with extra components. It is a lot more susceptible to influence and also put on damages due to the fact that the reducing side is at the pointer.

These kinds of blades need sharp teeth to reduce properly and also are usually gotten rid of. Honing a lot of these kinds of blades is hard and even difficult for the ordinary individual.

The much deeper the cut, the more probable it is that the blade will certainly kick as well as attack somehow. The even more teeth a blade has, the further it will certainly kick when it attempts to lack the port.

The much deeper the cut, the even more treatment has to be required to maintain the blade right, as turning somehow can trigger the blade to obtain embedded the reducing groove, leading to extreme recoil.

Cutting Ability

The majority of these kinds of blades are great at reducing flat to the optimum deepness it can reduce. Typically reducing branches with sizes higher than 50-60mm will certainly reduce swiftly.

Unlike table saws or ability saws, serrations cut in the instructions of traveling and also drag the product to the table surface area, stopping the job from recuperating. This permits the teeth to attack right into and also draw themselves right into the timber, as displayed in the relocating picture listed below.

This is due to the fact that the majority of lawnmowers are made for cord reducing that needs a high suggestion rate to make nylon-string crush greenery, and also they are not too matched to high torque as chain saws. Make use of a multi-tooth saw blade, the much deeper the cut, the extra reducing teeth, the better the resistance. This implies they call for even more power and also torque to drive, making them better for bigger equipment.

The greatest trouble with circular saw blades when you reduced bigger size branches is that you have an increasing number of serrations, all with little various reducing midsts and also rates. This results from the turning of the blade and also the instructions in which the blade is relocating. Consequently, when the blade relocates the instructions of the reducing branch, some teeth cut into the timber towards traveling. Some teeth were reduced on the timber, and also some teeth were cut on the contrary instructions of traveling as well as the elimination of the timber. This suggests that as the cut obtains much deeper, the opportunities of the blade being begun one instruction or the various other rises to the point where it is tough to regulate the blade.

Besides the brush cutter blade Clearing Machine, nothing else cutting as well as watering Machine has such an overview surface area. For that reason, with any other reducing maker, all of it depends upon the security with which you hold the completion of the reducing head and also which quadrant of the reducing blade. This implies that these sorts of blades can all of a sudden attack in, creating the blade to kick strongly. It’s like placing an ability saw right into an item of timber to begin reducing thoughtlessly as well as attempting to place it ahead.

Treatment capacity: These kinds of blades are generally inadequate in coverage due to the huge disc as well as do stagnate backward and forwards conveniently with shrubs.

Types of teeth

3 sorts of teeth are typically located on sculpt blades. When reducing the raw product, there are important blades where the teeth are of the exact same product as the entire blade as well as normally have offsets to give some blade clearance. There are chainsaw kind teeth that are either secured to the primary disc or are real power saw chains placed about as well as in between both discs. After that, there are tungsten carbide ideas, which are brazed to the disc.

Steel Teeth

As soon as the most typical is currently possibly the least typical, what was. There are some low-cost blades on ebay.com that do not have tooth offsets, which implies they have a tendency to embed damp SAP as well as I do not suggest acquiring them.

Incidentally, the most effective steel blades are those with great offsets, teeth comparable to chainsaw blades, and also can be developed with chainsaw data, as revealed listed below.

If you assume chisel-shaped blades are what you require, as well as you’re prepared to maintain them sharply, after that this is what I assume is the very best blade today. Significant brand names of reducing and also watering makers provide this sort of blade as an alternative. It’s a pity this blade does not have fewer teeth.

Chain Saw Teeth

The blade, which has a real power saw blade, is secured in between 2 steel plates.

Or an additional kind is the chain serrated section secured straight to a solitary steel plate.

The blade is a lot more vulnerable to the exact same recoil issues as the steel blade because of the really vast cuts of the chain teeth. Nevertheless, if you turn the lawnmower while making a deep cut, this vast cut does offer enough clearance as well as the blade is a lot less most likely to stick.

These teeth require to be maintained extremely sharp to reduce properly due to the fact that a lot of reducing makers have large reducing sizes and also improper equipment. With a little method, this is simple with conventional power saw data.

Forester additionally makes tungsten carbide-directed chainsaw blades that can be developed with ruby documents.

I made use of among them momentarily and also located that they did reduce well, however my lawnmower really did not actually have adequate time to drive it successfully. I likewise discovered that they are just helpful for reducing tree trunks much in the air. Utilize them anywhere near the ground, dirt might sandblast the idea, or go into the ground, and also these blades loosen up the blade at a suggestion rate. Unlike a chain saw, which has the reducing rate of the pointer, it is a tiny part of a mower’s blade.

Tungsten Carbide Teeth

When I initially released them, these blades are coming to be extra typical as they currently set you back regarding a quarter of the cost of the initial tungsten blade I acquired. These initial blades reduced quite possibly, yet they did not last long, as half the teeth were swiftly removed while reducing thick branches.

Blade, tungsten carbide pointer bonded to steel tooth pointer. Tungsten carbide is among the hardest alloys understood to hold sides well as well as hold up against huge effect lots, as discovered in stonework bits.

All it takes is a mild turn of the lawnmower, or the seedlings begin to ensnare the blade and also drop, as well as they’re below.

The only blades readily available today are those with teeth installed in steel, as opposed to bonded to the front of the steel teeth as revealed over.

Nevertheless, even if these very early idea-losing troubles have actually been resolved, the blades are not undestroyable. Although the alloy is hard when based on low-speed influence, it comes to be extra breakable when based on the high influence rates made use of in-water blades. Pointer rates vary from 300 to 450 km/h (180 to 280 MPH) relying on blade size. At these rates, striking acid rock readily, several teeth are most likely to ruin.

I assume in the very early days, they utilized the exact same saw that was placed on ability saw blades, which reduced at a steeper Angle, as received the reduced left. Nonetheless, this high Angle makes them much more susceptible to fragmentation when made use of in reducing makers that strike rocks and also steel fencing messages at dual ability saw blade rate. The more recent blades are more powerful, have a higher cutting Angle of virtually 85 levels, and also are bonded around the sides.

However thanks to the messy problems in Australia paired with extremely high suggestion rates, the dirt on the plants will certainly quickly brighten the reducing sides of this superhard alloy to a nearly invisible 0.05 mm span, as well as you’ll quickly find yourself attempting to melt your method via the timber. As opposed to a difficult however more powerful steel blade as revealed on the right, with a steeper cutting Angle reducing suggestion, can have a sleek side of 0.05 mm and also still reduce well.

Number of Teeth

In numerous remarks, you’ll check out that the much more the much better, and also if your thinking is the number of ideas you can rip off or cut up prior to the blade spoils, the extra the far better.

Much more teeth are not an issue when reducing tiny size seedlings, yet beginning reducing bigger size seedlings with just one tooth each time in the timber suggests no power loss. The drawback of having fewer teeth is that if you reduce a tooth, the efficiency and also level of smoothness of the cut can break down really rapidly.

The variety of teeth likewise influences the length of time your blade can reduce well prior to it being taken into consideration blunt. Chisel-type blades are most required when reducing seedlings of 50 mm (2 inches) and also above, however, with reducing equipment, even more teeth are much less. Due to the fact that the size of the retrencher shaft suggests that you decrease utilize and also can just use really restricted side pressure to the reducing teeth, this is. This was among the factors that the 4 teeth on the Model-11 flail blade were altered to one tooth on the Model-14 flail blade. Each flail blade has just one tooth, significantly enhancing reducing performance.

However, if you wish to obtain one of the most out of the power as well as really high tailoring of a lawnmower, much less is a lot more, and also I select the best blade each time. This puts on all 3 sorts of blades, with a couple of teeth as feasible.

There is just one tooth cutting, all the force enters into that a person tooth, 0.1 mm refined side does not have much impact on its reducing capability. Cut 10 teeth, each with a sleek side of 0.1 mm, use 1/10th of the force on each tooth, you simply can not press all those teeth right into it. Prior to you recognizing it, you’re attempting to brighten your means with, stay with it, and also you’re shedding your means via. You’ll be amazed at exactly how little time it requires to produce sufficient warmth to thaw the brazing that holds the tungsten teeth, leaving you questioning what occurs to those teeth.

Been there, done that.

Once more, this results in the exact same negative technique you commonly see on YouTube, rotating the garbage in the mower and afterward tossing the blade onto the branch. You can additionally loosen your teeth this way.

I ultimately saw an Australian supplier purposely make a blade with fewer teeth,

Notes; They also state it makes cutting smoother as well as quicker, minimizing recoil as well as exhaustion. It indicates you do not need to strive, which benefits them.

Since they understand much more, I believe you’ll locate this fad will certainly boost as even more and also even more individuals go right into shops asking for blades to minimize teeth.

Lastly, it resembles Shindaiwa who paid attention to me and also generated their LESS Equal to MORE Tornado 3 and also 6 collections of toothed watering device blades.

Smasher Blades

Nevertheless, because of the EU regulation, non-manufacturer requirements blades can be mounted on reducing watering makers in EU participant states, and also most of these blades are no more readily available, which could be a good idea. I’m presuming right here, however, I assume lots of one-piece blades if enabled to put on the blade out entirely, will certainly wind up smashing.

These sorts of blades do not have sharp sides as well as normally depend on their thinner density as well as the weight of the revolving blade or chain to squash plant life. These are generally revolving flail blades, weblink steel blades, as well as a variety of various sorts of chains.

Advantages: Keep the effectiveness of its collection style without preserving a benefit.

Generally appropriate for soft lawn and also water turf.

Faults: Since it is made from several components, it is generally much more costly.

Some, such as the web link blades, have extremely high resistance and also consequently eat a great deal of power simply to maintain revolving at a high adequate rate to properly squash plants as well as are for that reason preferable for higher-power devices.

Several are not made from ideal products to endure severe tons and also are for that reason typically anticipated to have a brief life.

Normally just helpful for yards as well as water plants, long-lasting squashing of woody weeds will certainly result in very early failing.

Cutting Ability

There are just a couple of flail mill blades on the marketplace. For lawn as well as water turf, this blade is extremely efficient, however, attempt reducing anything more difficult and also you’ll wind up attempting to shed your method. That’s due to the fact that its flail blades do not have the mass to pass through the denser weeds, so they simply maintain obtaining discarded.

I directly had actually been utilizing among these blades for some time prior to I chose to make my very own, and also it was this blade that encouraged me that flail blades were the only means to go. This blade is terrific for the yard as well as light water weeds, however, the lightweight flail blade does not have sufficient weight and also influences to the management of anything larger. I desired a blade that can do every little thing, and also there had not been anything like that, so I was required to make my very own blade.

Cutting Blade Manufacturers – The Ultimate FAQ Guide

Many people find it hard to choose from many cutting blade manufacturers. It’s because this decision is a crucial step in nurturing and growing their business.

In this guide, you’ll not just learn about cutting blades. By the end of this guide, you’ll be more than skilled to choose the best manufacturers for your cutting blades.

Sample image of different types and kinds of industrial blades

What is a Cutting Blade?

It’s a type of blade that you use in cutting a workpiece.

An image of what a cutting blade is

You’d want to use it because of its ability to cut swiftly and precisely compared to other products.

The different types of industrial custom metal cutting blades

What are Cutting Blades Made Of?

Since their main function is to cut through materials, their composition isn’t that complicated.

Raw ingredients in manufacturing or producing cutting blades

There are many different types that various cutting blade manufacturers produce. However, we’ll be able to separate and categorize them into blades that have metal bodies and blades with abrasive material.

More often than not, cutting blades are made out of carbide or steel for their bodies.

Their tips, however, are far sharper and more versatile – and are usually made out of tungsten carbide

More teeth means that the results would be finer and cleaner, less means that it’ll be finished faster

How Else Can You Use Cutting Blades?

Some cutting blade manufacturers advertise their products by straying from what it’s really for.

You can also use cutting blades to produce and manufacture combat knives

Apart from cutting, you can also use these types of blades for other purposes such as:

- Combat

- Preparation of Food and Ingredients

- Creasing (Fold lines)

- Etc.

You can choose to use them for other purposes you see fit, too! Whatever use or requirement you can do with its sharpness, and efficiency you can freely do so!

Which Manufacturer Makes the Best cutting blade

How are Cutting Blades Manufactured?

A lot of people think that cutting blades are simply pre-cut blades you use in your machines.

Cutting blades are heated in an industrial oven for hardening

But, that’s not how these cutters are made and manufactured.

- All raw materials are prepared, they include:

- Tool Steel (Metal Sheets)

- Other Metals and Alloys You Can Add

- Once all of those are prepared, the metal sheets are cut via lasers with the corresponding teeth amount

- After cutting, the discs are fed to rollers where grooves and creases are made. This is to keep the blade from vibrating while it’s being used

- Then, the blades are fed to a flattening machine, which will be what’s needed to keep them as is and flat

- The blades are then polished, freeing it from any inconsistency in the exterior, then they’re put in an oven where they’re heated for about 24 to 48 hours

- Next would be the integration of carbide tips to the cutting blade body through brazing

- Once done, the tips of the cutting blade is sharpened, sandblasted, and polished even more as a whole

That’s the regular structure of how cutting blade manufacturers make and produce their products.

Sample image of the best TPI for wood cutting

Different manufacturers might have different strategies and techniques. But, that’s the basic framework of how they’re manufactured.

What are the Different Types of Cutting Blade?

There are myriads of ways on how you can classify cutting blades.

An example of a diamond cutting blade manufactured by Tenyu Tools

But, it’ll be easier to categorize them based on the material they’re able to cut or slice through. Therefore, we can simply group them into the following

What’s the Standard Thickness of a cutting blade manufacturers

Wood Cutting Blades?

Cutting blade manufacturers often have a wood cutting blade in their arsenal.

These are the blades that are the most qualified to cut through all types of wood.

Metal and Steel Cutting Blades?

These blades, however, are purposely made and crafted to slice and cut through steel.

Even if these blades have stronger force, it’s not advisable to use them with other materials. You not only have the chance of damaging the teeth of your blades – you can also mess the workpiece up.

What kind of steel is a cutting blade made of

Grass Cutting Blades?

Grass cutters are blades that are ideally for the purpose of cutting grass.

They’re softer and more brittle; but oftentimes sharper because of the strength and toughness of the tips.

What arecutting blade manufacturers made up of

Rip Blade?

These are the most common types of cutting blades in the market.

You can use them for a wide range of materials – for plastic, PVC, wood, concrete, glass, etc. Be careful, though – just because they’re versatile doesn’t mean they’re going to be highly effective.

Diamond Cutting Blades?

Lastly, these are blades that are specific to their purpose of cutting and slicing through diamond.

Among the many different types of diamond cutters – dry diamond cutting blades are the most popular.

Pros of Working With Tenyu cutting blade manufacturers Tools

These are the different types of cutting blades you can purchase, depending on your operational needs.

You don’t have to know all of it – you can tell the manufacturer of your requirement; and that’s what they’ll help you with.

Are There Different Cutter Blades for Different Grades of Steel?

Yes, because of the fact that there’s a huge gap between different types and kinds of steel, there are specific types and kinds of cutting blades for it.

So, before purchasing a cutting blade, make sure that the blade you’ll purchase will work on the type of steel or metal that you have.

A good-quality wood cutting blade

Top Manufacturers of Cutting Blades

If you are faced with a dilemma of whom you should trust, don’t bother looking.

Here are some of the top cutting blade manufacturers you can find in the market:

- Freud

- Diamond Saw Works, Inc.

- PILANA

- DEWALT

- SKIL

Sounds easy, right? – What’s the catch?

Since these are all world-renowned manufacturers, it’s safe to say that almost all of their products are expensive.

Understanding cutting blade manufacturers

Using a Cutting Saw Blade Properly?

You just have to load the blade to the machine, turn the machine on, and proceed with cutting – right?

Checking a cutting blade if it’s at the right weight for a specific use

Many people tend to think of it as an easy task. When in reality, it actually involves a lot more than that.

Tipping Sharpening tct cutting blade manufacturers

Try following these tips in order for you to avoid breaking or damaging your cutting blades:

- Never put heavy loads on the saw blade, even when you’re not using it

- Pay close attention to the working conditions and specifications of your cutting blades

- Vibrations are never normal; if your cutting blades are vibrating, try changing it up. If the problem persists, consult your manufacturer immediately

- Refrain from using a different cutting blade for a different material (e.g. wood cutters for glass and metal)

These are just some of the most practical and the most common things you need to take note of when using cutting blades.

Tenyu Tools’cutting blade manufacturers

Cutting Blade Rates and Prices?

Cutting blades don’t have median prices – and it’s because of the raw materials you use for it.

There are a lot of things you need to consider to be aware of what the price is. It would include the:

- Make of the blade

- Type of carbide insert or tip

- Size or diameter of the blade

- The function of the blade

In addition to that, what’s also important is to contact various cutting blade manufacturers and ask about the rates and prices of their blades.

Tenyu Tools’ cutting blade manufacturers

Marble Cutting Blades vs. Metal Cutting Blades?

One of the most common misconceptions about cutting blades you use for marbles is that you can use it for metal too.

A metal or aluminum cutting blade with rough edges for smoother cuts

But, that’s not what the case is.

In fact using marble cutting blades for metal might be the reason for damaging or breaking. What you can use to cut marble are diamond cutters.

Take note of what type of cutting blade you’ll purchase; always remember that they’re not all the same.

Tenyu Tools’ cutting blade manufacturers

What Should You Look For in Cutter Saw Blades?

Choosing the right cutting blade is something you need to master. Imagine selecting the wrong one – it’s not only a waste of money, it could be a waste of time, too.

Straightening Tensioning cutting blade manufacturers

So, here are some top-tier tips on how you can choose the right cutting blade:

- Know the materials you’ll cut by heart. This is so you can choose the right type of cutting blade

- Thickness of the workpiece

- Shape of the workpiece

- Material composition of your target

- Speed requirement for the project completion

- Try doing a bit of research on the number of teeth (more teeth, smoother cut; fewer teeth, more materials removed or taken out)

- Determine the material the cutting blade you’re eyeing on is made of

- Don’t be afraid to compare the products of one manufacturer with another

You can also formulate questions of your own, specific to the types and kinds of cutting blades you need.

Signs That You Need a New Ccutting blade manufacturers

What are Cutting Blade Machines?

Cutting machines are machines where you mount or load your blades onto.

It’s the type of equipment that can help you fire up your blades to do and perform the cutting.

OEM and ODM Can They Be Trusted cutting blade manufacturers

How Do You Choose the Cutting Blade Manufacturer to Work With?

It’s true that not all cutting blades are the same. What’s true is that they’re different based on a lot of different factors including:

- Their usage

- The material they can cut

- Their size

- The number of teeth

- Etc

All cutting blade manufacturers have different products – but how do you choose the manufacturer you can go with and trust?

Inspect the cutting blade manufacturers Close-up

Here are some of the things that you need to look for to choose the best and the most appropriate cutting blade manufacturer you need to take note of:

- Tenure and Experience in the Field

- Quality of the Cutting Blades (you can ask for samples)

- Features of the Cutters They’re Offering

- Company and Product Certifications and Licenses

- Etc

By looking at the following factors and information, you’ll immediately be able to tell if a manufacturer or a supplier is someone you can trust.

How to Welding Teeth forcutting blade manufacturers

What Can You Cut With Cutting Blades?

As we’ve discussed above, there are certain cutting blades you can use for different types and kinds of material.

But, to give you some of the most common objects and materials you can cut, they are:

- Plastic and PVCs

- Glasses and Glassware

- Metal and Steel (Different Grades)

- Wood

- Marble and Concrete

- Diamonds

These are some of the most common materials that companies and businesses cut. But, if you have other variants – take asphalt, for instance, you can categorize it to be part of concrete – make sure that you select the appropriate blade for it.

How to Polish Teeth for cutting blade manufacturers

Cutting Blade for Wooden Doors?

It’s quite a no-brainer to think that the cutting blades for wood are the type you need to cut wooden doors.

However, you also need to note that not all wood is the same. So, if you are to cut wooden doors, you’d want to make sure that your cutting blade would be the type that has 18 teeth at the minimum.

Why? Because the edges of your door need to be smooth; also, the cutting would be faster if you utilize cutting blades that have more teeth.

How to Choose a cutting blade manufacturers to Work WIth

Which Cutting Blade Manufacturer Can You Trust?

Among the ocean of manufacturers and suppliers you can choose from, there’s no other company you can trust here in China but us at Tenyu Tools Co., Ltd.

For more than 10 years, we’ve been the go-to supplier of all lower-rated cutting blade manufacturers globally.

How Long Should cutting blade manufacturers Last

We’re the best not only because of the skill and the talent of our personnel; but also because of the fact that we’ll be able to help you produce custom cutting blades.

Whether you need a cutting blade at a specific diameter; or you need to modify the teeth count of the blades you want, Tenyu Tools will never fail you.

Contact us and get a free quotation of the blades that you’re specifically looking for. Work with the best cutting blade supplier in the region and never fail at whatever project you have!

- You can order from us wherever you are global – get it within 2 to 3 weeks!

- You’ll experience unrelenting customer service and support

- Your power tools will be equipped with the best and the latest technology

- You’ll never fail using our tools – we’re certified and licensed!

Custom Industrial Blades

There are multiple retail stores and outlets where you can purchase custom industrial blades.

As a matter of fact, you can even find a lot of custom industrial blades manufacturing companies from all across the globe.

How Do You Choose the cutting blade manufacturers to Work With

You can find tons in Asian countries like India, China, Vietnam, Indonesia, and many more! In fact, if you’re going to use it for business, like retailing or reselling them, getting them from a custom industrial blade wholesaler is the best option to take.

Some of the industry’s top custom industrial blade suppliers include Docksaw, Baycor, Radenceblades, RKMK UK, Tenyu Tools Co., Ltd., and many more!

How Do cutting blade manufacturers Produce TCT Circular Blades

Different Types of Metal Cutting Blades

It might bewilder you to find that there are multiple types of metal cutting blades in the market. As a matter of fact, there’s no single type of way to determine the type of metal cutting blade.

But, the most common way to identify them would be by knowing them through their teeth.

Benefits of Choosing Tenyu Tools cutting blade

- Flat Top

- Alternate Top Bevel

- Combination Tooth

- Triple Chip Grind

- High Alternate Top Bevel

NOTE: This is not just the only way to identify cutting blade manufacturers. It’s just the most common, but it’s not all there is!

Custom cutting blade

Metal Cutting Blade Price

Contrary to popular belief, there’s no average to the price or cost of metal cutting blades. In fact, it’ll depend on the overall make and process on how it was done.

Generally, though, you will be able to find a lot of metal cutting blades in the industry that are priced between $2 and $4. Take note, though, that those are low quality cutting blades and might not last longer than what you are expecting.

Can I use a cutting blade on a table saw

There are, however, metal cutting blades that are priced at around $8. These are the better and higher quality cutting blades that are least likely to fail even if you use them for longer periods of time.

That’s too much, yes, and it’s something that can be a burden to you and to your business. Little did you know that there are good-quality cutting blades that you can purchase for less than $3! That’s by going and working directly with a cutting blade manufacturer like us here at Tenyu Tool!

Can cutting blade Cut Aluminum_

We’re able to produce and provide the best and highest qualities of cutting blades regardless of the size and the design that you need it for. We are a Chinese cutting blade manufacturer that you can definitely trust for the custom cutting blades that you need.

Is More Teeth on a Saw Blade Better?

The number of teeth on the saw blade does not determine whether or not it’s good. What it determines would be the speed and the quality or type of the finish or the cut.

Are cutting blade manufacturers the Same With Table Saw Blades_

The more teeth on a saw blade, the finer and the cleaner the finish is, but it will take longer. Saw blades that have fewer teeth can finish the job faster, but, it wouldn’t be as clean and as high quality as cutting with saw blades with more teeth.

What TPI is Best For Cutting Wood?

TPI, short for teeth per inch, is the term used to identify the number of teeth in an inch of the edge of the saw blade.

Are cutting blade manufacturers the Same With Table Saw Blades_

Ideally, the best TPI for woodcutting would be about 6 to 20.

On the contrary, for cutting metals, the best and most ideal TPI would be between 14 and 36. You can go above 36 to about 40 to 42; that would hasten the process, but can give you lower quality of the finish.

So, more teeth on a saw blade won’t actually refer to the quality of the cut. Instead, it’s going to depend on the results you’re looking for as well as the speed of the procedure.

What Do You Need to Look For in a Cutting Blade?

While there are many different properties of cutting blades, there are some features and specifications that stand out when it comes to choosing what the best and most ideal is.

Do cutting blade Have Universal Sizes_

So, what do you need to look for in a cutting blade? What are the top things that would be possible to influence your decision?

There are quite a few factors that can help you with your decision in choosing a cutting blade. Among the most common would include:

Number of Teeth

Of course, this is the specification that determines the total number of teeth on a cutting blade.

Kerf

The kerf is the width or the size of the tooth taken at its widest point. This determines the width of the cut.

Rake Angle

This is the angle or the position of the tooth in accordance to the cutting surface. It’s determined through the positive and negative angle.

Are There cutting blade for Metal_

Gullet Size

Gullet size is the space or distance between the teeth, depth, and size. You’ll immediately see the size of the gullet through the teeth count.

These are the things that are important and relevant when you’re trying to find good-quality cutting blade.

Iron Cutting Blade Manufacturers in China

There are a lot of iron cutting blade manufacturers in the country. But, of course, the best and the most trusted supplier of iron cutting blade is none other than us here at Tenyu Tool.

Applications of Tenyu Tools’ cutting blade manufacturers

For years, we have been banked on in the industry as the best iron cutting blade manufacturer. Some of the features of our iron cutting blades include:

- They can cut through thick and hardwood, even metal like aluminum.

- It’s sized at about 110 to 600mm

- We can have your logo printed on the body of the cutting blade

- You can use our cutting blades for various types of saw machines

- Our industrial cutting blades are lightweight and easy to use

Applications of Our cutting blade manufacturers

Don’t hesitate to give us a buzz for the wood, marble, steel – even diamond cutters you need!

[toc]