Foret DIN 1897

Perçage ponctuel précis sans centrage, même sur des surfaces courbes.

Foret hélicoïdal court et stable avec une résistance à la chaleur distinctive.

notre expertise

Forte dureté pour le perçage et obtenez un perçage bien fait !

Livraison rapide

Fabricant professionnel de forets Din 1897, Inventaire suffisant

Qualité inspectée

Notre société dispose de 7 systèmes stricts pour vérifier la qualité du produit.

service de boxe

Tous les colis sont conformes à la livraison de conteneurs par voie maritime ou aérienne

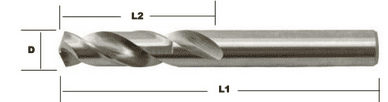

Forets DIN 1897

Forets hélicoïdaux à queue droite HSS DIN 1897 --- Fabricant d'outils Tenyu

DIN 1897 FORET EXTRA COURT MÈCHES HSS STUB TWIST

Diamètre : 1-20 mm

Processus de fabrication : laminé, fraisé, entièrement rectifié

Type de flûte : N

Matériau : HSS4241, HSS4341, HSS M2 (6542), HSS M35 (Co5%), HSS M42 (Co8%).

Finition : blanc, revêtement en étain, couleur arc-en-ciel, brillant, noir et brillant, revêtement en zirconium, noir, couleur café, etc.

Angle de pointe : 118 ou 135 points de partage (point de meulage point de partage de  ̄ 3 mm.)

1. Le point à 118 degrés est parfait pour les mobiles et les appareils ennuyeux. Fait à faire en acier au carbone modéré et également réduit, en fonte ainsi qu'en bois.

Le point de partage de 2,135 degrés est auto-centrant et minimise également l'entraînement. Parfait pour l'exploration mobile ou d'appareils de produits en alliage à résistance à la traction réduite, en acier inoxydable, ainsi que diverses autres applications d'obligation d'outils.

Photos pour MÈCHES COBALT DIN1897 AVEC AMBRE

Photos pour PERCEUSE HSS M2 DIN1897 AVEC LUMINEUX

Image pour DIN 1897 FORET HSS EXTRAC COURT HSS TRONÇON MÈCHES À TORSION AMBRE COBALT

Combinaison de forage DIN 1897 :

- travail durable

- Précision de course réelle élevée

- Homme de droite réduisant/.

- fabricants de mats automatisés et aussi tours à tourelle et aussi fabricant de perceuses à main.

- Haute résistance à la chaleur.

- ennuyeux à l'acier, acteurs de fer gris, aciers non ferreux.

Foret durable DIN 1897 pour une utilisation sur des appareils automatisés et également des institutions financières à revolver. Particulièrement adapté pour une utilisation dans les perceuses à main ainsi que pour le perçage de produits à parois minces (carrosserie, etc.).

HSS Photo for DIN 1897 FORET HSS EXTRAC COURT HSS STUB TWIST FORET AVANTAGES

Foret DIN 1897 stable et à rotation courte avec une résistance à la chaleur distincte. Idéalement adapté pour la mise en place de produits à parois minces tels que les tôles d'acier, les aciers de niveau ainsi que l'acier de compte dans la construction de carrosseries.

20% réduit la pression d'alimentation contrairement aux forets DIN 338 en plus d'un développement plus rapide ainsi que d'un moyen de travail beaucoup plus doux.

Vitesse de coupe jusqu'à 50% supérieure à celle des forets DIN 338

Photos de DIN 1897 FORET HSS M2 EXTRA COURT MÈCHES HSS STUB TWIST FORETS

Spécifications des mèches hélicoïdales à embout HSS extra court Din 1897

| ré | L1 | L2 | ré | L1 | L2 | ré | L1 | L2 | ré | L1 | L2 |

| 1 | 6 | 26 | 5.8 | 28 | 66 | 10.8 | 47 | 95 | 15.5 | 58 | 116 |

| 1.2 | 8 | 30 | 6 | 28 | 66 | 11 | 47 | 95 | 15.75 | 58 | 116 |

| 1.5 | 9 | 32 | 6.2 | 31 | 70 | 11.2 | 47 | 95 | 16 | 58 | 116 |

| 1.8 | 11 | 36 | 6.5 | 31 | 70 | 11.5 | 47 | 95 | 16.25 | 60 | 119 |

| 2 | 12 | 38 | 7 | 34 | 74 | 11.8 | 47 | 95 | 16.5 | 60 | 119 |

| 2.2 | 13 | 40 | 7.2 | 34 | 74 | 12 | 51 | 102 | 16.75 | 60 | 119 |

| 2.5 | 14 | 43 | 7.5 | 34 | 74 | 12.2 | 51 | 102 | 17 | 60 | 119 |

| 2.8 | 16 | 46 | 7.8 | 37 | 79 | 12.5 | 51 | 102 | 17.25 | 62 | 123 |

| 3 | 16 | 46 | 8 | 37 | 79 | 12.8 | 51 | 102 | 17.5 | 62 | 123 |

| 3.2 | 18 | 49 | 8.2 | 37 | 79 | 13 | 51 | 102 | 17.75 | 62 | 123 |

| 3.5 | 20 | 52 | 8.5 | 37 | 79 | 13.2 | 51 | 102 | 18 | 62 | 123 |

| 3.8 | 22 | 55 | 8.8 | 40 | 84 | 13.5 | 54 | 107 | 18.25 | 64 | 127 |

| 4 | 22 | 55 | 9 | 40 | 84 | 13.8 | 54 | 107 | 18.5 | 64 | 127 |

| 4.2 | 22 | 55 | 9.2 | 40 | 84 | 14 | 54 | 107 | 18.75 | 64 | 127 |

| 4.5 | 24 | 58 | 9.5 | 40 | 84 | 14.25 | 56 | 111 | 19 | 64 | 127 |

| 4.8 | 26 | 62 | 9.8 | 43 | 89 | 14.5 | 56 | 111 | 19.25 | 66 | 131 |

| 5 | 26 | 62 | 10 | 43 | 89 | 14.75 | 56 | 111 | 19.5 | 66 | 131 |

| 5.2 | 26 | 62 | 10.2 | 43 | 89 | 15 | 56 | 111 | 19.75 | 66 | 131 |

| 5.5 | 28 | 66 | 10.5 | 43 | 89 | 15.25 | 58 | 116 | 20 | 66 | 131 |

DIN 1897 FORETS EXTRA COURTS HSS STUB TWIST FORETS LISTE DES ÉLÉMENTS CHIMIQUES

| Din 1897 Forets Matériel NO. | acier NON. | ANALYSE CHIMIQUE (%) | |||||||||

| C | Si | Mn | P | S | Cr | O | mois | V | |||

| Din 1897 Forets 4241 | W4Mo2Cr4VSi | 0.90 | 1 | 0.30 | ≤0,030 | ≤0,015 | 4.8 | 1.6 | 0.65 | 0.55 | |

| 1.00 | 1.3 | 0.40 | 5.1 | 1.85 | 0.8 | 0.7 | |||||

| Din 1897 Forets 4341 | W4Mo3Cr4VSi | 0.89 | 0.60 | 0.30 | ≤0,030 | ≤0,015 | 3.80 | 3.60 | 2.60 | 1.25 | |

| 0.97 | 1.00 | 0.40 | 4.40 | 3.85 | 2.85 | 1.45 | |||||

| Din 1897 Forets 9341 | W9Mo3Cr4V | 0.78 | 0.20 | 0.30 | ≤0,030 | ≤0,015 | 3.80 | 8.60 | 2.80 | 1.35 | |

| 0.86 | 0.40 | 0.40 | 4.40 | 8.90 | 3.05 | 1.55 | |||||

| Forets DIN 1897 M2 | W6Mo5Cr4V2 | 0.81 | 0.20 | 0.30 | ≤0,030 | ≤0,015 | 3.80 | 5.60 | 4.60 | 1.80 | |

| 0.89 | 0.45 | 0.40 | 4.40 | 5.85 | 4.85 | 2.00 | |||||

| Din 1897 Forets Cobalt M35 | W6Mo5Cr4V2Co5 | 0.88 | 0.20 | 0.30 | ≤0,030 | ≤0,015 | 3.80 | 5.60 | 4.60 | 1.80 | Co : 4,60 |

| 0.95 | 0.45 | 0.40 | 4.40 | 5.85 | 4.85 | 2.00 | 4.85 | ||||

| Din 1897 Forets Cobalt M42 | W6Mo5Cr4V2Co8 | 1.05 | 0.15 | 0.15 | ≤0,030 | ≤0,015 | 3.5 | 1.15 | 9 | 0.95 | Co : 7,75 |

| 1.15 | 0.65 | 0.4 | 4.25 | 1.85 | 10 | 1.35 | 8.75 | ||||

Envoyez votre demande aujourd'hui

Comprehensive FAQ About DIN 1897 Drill

This FAQ offers a deep dive into DIN 1897 drills, covering their features, applications, and advantages. The detailed insights below provide a full understanding of these precision tools, tailored for professionals and DIY users.

1. What Is a DIN 1897 Drill?

A DIN 1897 drill refers to a specific type of drill bit that adheres to the DIN 1897 standard, established by the German Institute for Standardization (Deutsches Institut für Normung). This standard specifies dimensions, materials, and performance criteria for short-length drill bits, ensuring consistent quality and reliability.

2. What Are the Key Features of DIN 1897 Drills?

DIN 1897 drills are characterized by the following features:

- Short Length: These bits are shorter than standard drill bits, making them ideal for precision tasks and confined spaces.

- High-Speed Steel (HSS): Typically made from HSS, they offer excellent durability and heat resistance.

- Precise Dimensions: The DIN 1897 standard ensures uniformity in length, diameter, and cutting performance.

- Versatile Applications: Suitable for drilling a wide range of materials, including metal, wood, and plastics.

3. How Do DIN 1897 Drills Differ from Standard-Length Drill Bits?

DIN 1897 drills are significantly shorter than standard-length bits, offering several advantages:

- Improved Stability: The reduced length minimizes wobbling, ensuring precise drilling.

- Greater Durability: Shorter bits are less prone to bending or breaking under pressure.

- Tight Space Accessibility: Their compact size makes them ideal for working in confined areas.

4. What Materials Are DIN 1897 Drills Made From?

DIN 1897 drills are predominantly made from high-speed steel (HSS), which provides the following benefits:

- Heat Resistance: Maintains cutting efficiency even at high speeds.

- Durability: Withstands repeated use on hard materials.

- Sharp Cutting Edges: Ensures clean, precise holes in various materials.

Some DIN 1897 drills are also coated with materials like titane or cobalt to enhance wear resistance and prolong their lifespan.

5. What Are the Common Applications of DIN 1897 Drills?

DIN 1897 drills are versatile tools used in a variety of industries and tasks, including:

- Metalworking: Drilling holes in steel, aluminum, and other metals.

- Woodworking: Creating precise holes in hardwood and softwood.

- Plastic Fabrication: Suitable for acrylics and other rigid plastics.

- DIY Projects: Ideal for hobbyists working on detailed or small-scale tasks.

6. Why Choose DIN 1897 Drills for Metalworking?

DIN 1897 drills are particularly well-suited for metalworking due to their precision and durability. Their shorter length provides increased stability, reducing the risk of bit breakage or inaccurate drilling when working with hard metals like stainless steel.

7. Can DIN 1897 Drills Be Used on Soft Materials Like Wood or Plastic?

Yes, DIN 1897 drills are highly effective on soft materials like wood and plastic. Their sharp cutting edges and stable design ensure clean and precise holes without splintering or cracking the material.

8. What Is the Difference Between DIN 1897 and DIN 338 Drills?

- Length: DIN 1897 drills are shorter, while DIN 338 drills have a standard length.

- Application: DIN 1897 drills are ideal for precision work and confined spaces, whereas DIN 338 drills are better suited for general-purpose drilling.

- Stability: The shorter length of DIN 1897 drills offers greater stability during drilling.

9. What Are the Advantages of Using DIN 1897 Drills?

DIN 1897 drills offer several advantages, including:

- Precision: Ensures accurate hole placement in both hard and soft materials.

- Efficiency: Their short length reduces vibration and enhances control.

- Versatility: Suitable for a wide range of materials and applications.

- Durability: Made from HSS, these bits are built to withstand demanding tasks.

10. How to Choose the Right DIN 1897 Drill for Your Project?

To select the appropriate DIN 1897 drill, consider the following factors:

- Material: Match the drill’s material (HSS, cobalt, etc.) to the material you’re working with.

- Diameter: Choose a size that fits the specific hole diameter you need.

- Coating: Opt for coatings like titanium or cobalt for improved durability in challenging applications.

11. What Coatings Are Available for DIN 1897 Drills?

DIN 1897 drills are available with various coatings to enhance their performance:

- Titanium Coating: Reduces friction and increases wear resistance.

- Cobalt Coating: Enhances heat resistance for drilling hard metals.

- Black Oxide Coating: Provides corrosion resistance and improves durability.

12. How to Maintain DIN 1897 Drills?

Proper maintenance extends the lifespan of your DIN 1897 drills:

- Clean After Use: Remove debris and cutting residue after each use.

- Store Properly: Keep drills in a protective case to avoid damage.

- Sharpen Regularly: Use a drill bit sharpener to maintain cutting edges.

- Use Lubricants: Apply cutting oil when drilling metals to reduce heat and friction.

13. Are DIN 1897 Drills Suitable for Professional Use?

Yes, DIN 1897 drills are widely used by professionals across industries such as metalworking, construction, and manufacturing. Their precision and durability make them a reliable choice for demanding applications.

14. What Are the Recommended Drill Speeds for DIN 1897 Drills?

The recommended drill speed depends on the material being drilled:

- Steel: Use a low speed to prevent overheating.

- Aluminum: Moderate speed works best for clean holes.

- Wood: Higher speeds are suitable for softwood, while hardwood may require slower speeds.

15. Can DIN 1897 Drills Be Used with Cordless Drills?

Yes, DIN 1897 drills are compatible with cordless drills. Their short length and precise design make them ideal for portable drilling tasks in various settings.

16. What Are the Limitations of DIN 1897 Drills?

While DIN 1897 drills are highly versatile, they may not be ideal for:

- Deep Holes: Their short length limits the depth of holes they can drill.

- Heavy-Duty Applications: For extremely tough materials, longer or specialty bits may be required.

17. What Is the Standard Length of a DIN 1897 Drill?

The length of DIN 1897 drills varies depending on the diameter, but they are generally shorter than standard bits, making them ideal for precision tasks and confined spaces.

18. How Do You Avoid Breaking a DIN 1897 Drill Bit?

To prevent breaking a DIN 1897 drill bit:

- Use the Right Speed: Adjust the drill speed according to the material.

- Apply Steady Pressure: Avoid forcing the bit into the material.

- Lubricate the Bit: Use cutting oil for metals to reduce heat and friction.

- Secure the Material: Ensure the workpiece is clamped or held firmly in place.

19. Are DIN 1897 Drills Cost-Effective?

Yes, DIN 1897 drills are cost-effective due to their durability and versatility. Their ability to handle a wide range of materials and tasks makes them a valuable investment for professionals and hobbyists alike.

20. Where Can You Purchase High-Quality DIN 1897 Drills?

High-quality DIN 1897 drills are available from reputable manufacturers like OUTIL TENYU, which ensures precision-engineered bits suitable for a variety of applications.

21. What Are Short Drill Bit Sets?

Short drill bit sets consist of drill bits designed with reduced lengths compared to standard bits. These bits are ideal for applications requiring precision, stability, and access to confined spaces. Their shorter length minimizes flexing, making them especially effective for accurate drilling in metal, wood, and other materials.

22. What Are the Advantages of Short Drill Bits?

Short drill bits offer several advantages over standard-length bits:

- Improved Stability: Their shorter length reduces wobbling, ensuring precision drilling.

- Ideal for Tight Spaces: These bits are perfect for use in confined or hard-to-reach areas.

- Reduced Breakage Risk: With less flex, short drill bits are less likely to break under pressure.

- Enhanced Accuracy: Suitable for tasks requiring precise hole placement, such as metalworking and cabinetry.

23. What Is a Stub Drill Bit?

A stub drill bit, also known as a short-length drill bit, is specifically designed for applications requiring maximum stability. These bits are commonly used in metalworking, where precision is critical, and are defined by their compliance with standards such as DIN1897, which regulates their dimensions and performance.

24. What Materials Are Used to Make Short Drill Bits?

Short drill bits are made from high-quality materials to suit a variety of applications:

- High-Speed Steel (HSS): Ideal for general-purpose drilling in wood, plastic, and soft metals.

- Titanium-Coated HSS: Provides enhanced durability and reduces friction, extending bit life.

- Cobalt-Alloyed HSS: Perfect for drilling through hard metals like stainless steel.

- Carbide-Tipped Bits: Designed for heavy-duty applications, such as drilling through concrete or hardened steel.

25. What Is DIN1897, and How Does It Relate to Short Drill Bits?

DIN1897 is a German standard that defines the specifications for short-length drill bits. It covers dimensions, material requirements, and performance metrics, ensuring that the bits meet industry standards for precision and durability. Drill bits compliant with DIN1897 are often preferred for professional applications due to their reliability.

26. How Are Short Drill Bit Sets Organized?

Short drill bit sets are typically organized based on size, material, and intended application:

- Size Range: Common sizes range from 1mm to 13mm in diameter, with varying lengths.

- Material Type: Sets often include HSS, titanium-coated, or cobalt bits.

- Application-Specific Sets: Some sets are tailored for wood, metal, or multi-material drilling.

27. What Are Hex Shank Drill Bits?

Hex shank drill bits feature a six-sided shank that provides a secure grip in the chuck, preventing slippage during drilling. These bits are particularly useful in high-torque applications and are compatible with quick-change systems for efficient bit swapping.

28. What Are Hex Shank Drill Bits for Metal?

Hex shank drill bits for metal are designed to drill through tough materials like steel, aluminum, and brass. They are made from durable materials such as cobalt-alloyed HSS or titanium-coated steel to withstand high heat and pressure during drilling.

29. How Are Short Hex Shank Drill Bits Different from Standard Hex Shank Bits?

Short hex shank drill bits combine the advantages of hex shanks with the stability of short-length bits:

- Increased Precision: The shorter length minimizes wobbling during drilling.

- Better Accessibility: Ideal for tight spaces where standard-length bits may not fit.

- Enhanced Durability: Their robust design reduces the risk of breakage.

30. What Are the Applications of Short Drill Bits for Metal?

Short drill bits are commonly used in metalworking applications, including:

- Automotive Repairs: Drilling through engine components or metal frames.

- Construction Projects: Creating holes in metal beams or brackets.

- Industrial Manufacturing: Precision drilling in metal parts and components.

31. What Are Titanium Hex Shank Drill Bits?

Titanium hex shank drill bits are coated with titanium to improve wear resistance and reduce friction during drilling. These bits are suitable for high-speed drilling in materials such as wood, plastic, and soft metals.

32. How Do You Use Short Drill Bits for Woodworking?

Short drill bits are ideal for woodworking tasks that require precision and stability. When drilling into wood:

- Select the Right Bit: Use HSS or hex shank wood drill bits for clean, precise holes.

- Adjust the Drill Speed: Use slower speeds for hardwoods and higher speeds for softwoods.

- Secure the Workpiece: Clamp the wood to prevent movement during drilling.

33. What Are the Best Practices for Using Short Drill Bits?

- Choose the Right Material: Use HSS for general applications, cobalt for hard metals, and carbide-tipped bits for concrete.

- Keep the Bit Cool: Use cutting oil or water when drilling metal to prevent overheating.

- Apply Steady Pressure: Avoid forcing the bit into the material, which can cause breakage.

- Store Properly: Keep bits organized in their set to avoid damage and ensure easy access.

34. What Are Stubby Drill Bits?

Stubby drill bits are ultra-short drill bits designed for maximum stability and control. They are often used in tight spaces or applications requiring precision, such as drilling holes for dowels or fasteners.

35. Can Short Drill Bits Be Used with Impact Drivers?

Yes, short hex shank drill bits are compatible with impact drivers. Their secure grip in the chuck and durable construction make them ideal for high-torque applications, such as driving screws or drilling metal.

36. How Do You Select the Right Short Drill Bit Set?

When choosing a short drill bit set, consider the following factors:

- Material: Select HSS for general use, cobalt for hard metals, and titanium-coated bits for extended life.

- Size Range: Choose a set that includes the sizes you need for your projects.

- Intended Use: Ensure the set is designed for the materials you’ll be working with, such as wood, metal, or plastic.

37. What Are Hexagonal Drill Bit Sets?

Hexagonal drill bit sets include a variety of hex shank drill bits, making them compatible with a wide range of tools. These sets often feature bits for wood, metal, and plastic, offering versatility for different applications.

38. What Are Short Drill Bits for Wood?

Short drill bits for wood are specifically designed to drill clean, precise holes in softwoods and hardwoods. They are often used in cabinetry, furniture making, and DIY projects where accuracy is essential.

39. What Is a Hex Shank HSS Drill Bit Set?

A hex shank HSS drill bit set includes high-speed steel bits with hex shanks for added stability. These sets are ideal for drilling into wood, plastic, and light metals and are compatible with quick-change systems.

40. Where Can You Purchase High-Quality Short Drill Bit Sets?

Reputable manufacturers like OUTIL TENYU offer durable and reliable short drill bit sets. Their products are designed for professional and DIY use, ensuring precision and longevity in various applications.

Conclusion

DIN 1897 drills are essential tools for precision drilling in metal, wood, and plastics. By adhering to strict standards, these bits deliver consistent performance and durability. For reliable and high-quality DIN 1897 drills, visit OUTIL TENYU. Follow the best practices outlined above to achieve optimal results in your projects.

DIN 1897 drills are essential tools for precision drilling in metal, wood, and plastics. By adhering to strict standards, these bits deliver consistent performance and durability. For reliable and high-quality DIN 1897 drills, visit OUTIL TENYU. Follow the best practices outlined above to achieve optimal results in your projects.