Can diamond blades cut metal? It’s a question I’ve heard time and time again. Whether you’re a DIY enthusiast or a professional, finding the right tool for cutting metal can make all the difference. Let’s dive into this, keeping things straightforward and simple.

No, diamond blades are not suitable for cutting metal. They are designed for hard materials like stone, tile, or concrete. Using diamond blades on metal can be dangerous due to diamond particles flying off. It’s best to use blades specifically made for metal cutting to ensure safety and efficiency. It is highly recommended to use a blade specifically designed for cutting metal.

So, let’s break this down into the details you really need.

Using a Tile Diamond Blade to Cut Sheet Metal?

If you’re thinking about cutting sheet metal with a tile diamond blade, there are a few important things to consider. Tile blades are primarily designed for ceramic, but they can cut through sheet metal in a pinch.

However, it is not recommended to use a tile diamond blade to cut sheet metal. Not only is it ineffective, but it also poses significant safety risks due to diamond particles potentially flying off during the process. Metal is a much tougher material than ceramic, and without the appropriate cutting tool, you could risk not only damaging the material but also injuring yourself.

Why Tile Blades Are Not Suitable for Metal

Tile blades are primarily designed to work on brittle materials like ceramic and porcelain, which are fundamentally different in structure and composition from metal. Metal is a malleable material that requires a different cutting approach. The diamond segments on a tile blade are excellent for grinding and abrading ceramics but are not sharp or tough enough to effectively slice through metal. Additionally, attempting to force a tile blade through sheet metal can lead to overheating, increased friction, and damage to the blade itself.

Another key reason why tile blades are unsuitable for cutting metal is the lack of teeth. Metal cutting requires a blade with teeth that can shear and cut through the metal fibers. Tile blades, on the other hand, have a smooth or segmented rim designed to grind, rather than shear. When used improperly, these blades can become dull, overheat, or even break apart, leading to dangerous situations.

What Works Best?

- For small DIY projects, using what you have (like a tile diamond blade), is risky and generally not recommended. Get a specialized blade meant for cutting metals—it’ll save time, produce cleaner results, and significantly reduce the risk of injury.

- Metal Cutting Blades: Use a ferrous metal cutting blade for steel or iron, and a non-ferrous blade for softer metals like aluminum or copper. These blades are designed specifically for cutting metals, ensuring that you get a clean, efficient cut every time.

What are Diamond Blades and Their Types?

Diamond blades aren’t just a one-size-fits-all. There are different types tailored for specific jobs. The choice of blade depends largely on the type of material you want to cut. Understanding the different types of diamond blades and their purposes will help you choose the right one for each job.

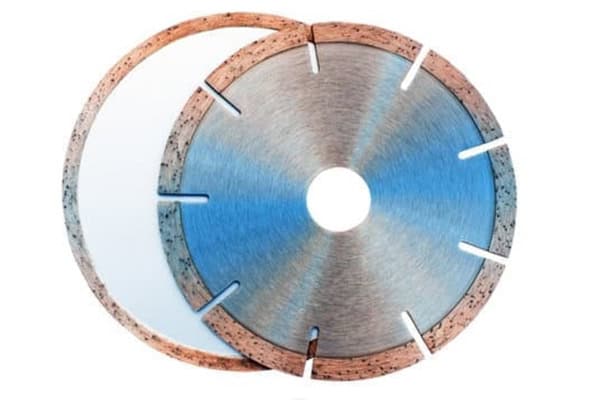

Diamond blades are circular saw blades with diamond particles embedded along their edges. The diamonds help grind and cut through tough materials like masonry or stone. Depending on the type, these blades can be used dry or with water to cool and minimize dust.

Main Types of Diamond Blades

There are three main types of diamond blades:

- Lames segmentées: Made for concrete and masonry; not ideal for precision cuts but great for fast cutting. These blades are characterized by the serrated, segmented rim, which provides fast cutting speeds while allowing efficient debris removal. Segmented blades are perfect for aggressive cutting of hard materials like brick, concrete, and limestone.

- Turbo Blades: These have a smooth rim with small serrations that help increase the cutting speed. They are suitable for tough materials and leave a cleaner edge compared to segmented blades. The design of turbo blades allows for better cooling and debris removal, making them a good choice for cutting natural stones, ceramic tiles, and even some masonry.

- Lames à jante continue: Best for cutting materials like tile or porcelain, giving you a smoother finish. Continuous rim blades have a non-serrated edge, allowing for precise, clean cuts. These blades are designed to operate wet, which helps minimize dust and cool the blade, reducing the risk of overheating.

The Science Behind Diamond Blades

The cutting ability of diamond blades relies on the abrasive nature of diamonds. Diamonds are one of the hardest substances known, and when embedded into the blade’s rim, they grind away at the material being cut. Unlike traditional saw blades that have teeth to shear through materials, diamond blades work by friction. The diamonds themselves do not cut in the traditional sense; instead, they remove material through abrasion.

This unique approach is particularly effective for materials like concrete and stone, where traditional saw blades struggle to create a smooth finish.

| Type de lame | Suitable Materials | Caractéristiques et avantages |

|---|---|---|

| Lames segmentées | Concrete, Masonry, Brick | Fast cutting, good debris removal |

| Turbo Blades | Stone, Ceramic, Masonry | Faster cutting, cleaner edge |

| Lames à jante continue | Tile, Porcelain | Precise, smooth cut, wet cutting |

What Makes a Durable Diamond Blade?

Durability in diamond blades comes down to several factors, but it’s all about understanding what makes them last longer.

Durability Factors

Diamond blades are crafted for endurance, but the bond hardness et diamond quality determine how well it performs and lasts. The bond holds the diamonds in place. A harder bond means the blade wears down slower, ideal for softer materials. For metal, a softer bond is better, ensuring fresh diamonds are always exposed as you cut.

Other important considerations are:

- Usage Frequency: More frequent use equals more wear. If the blade is being used daily on tough materials, its lifespan will be shorter compared to occasional use on softer materials.

- Proper Handling: Overheating due to incorrect handling or high RPMs can damage a blade, so always check the specifications for the best results. Proper cooling is essential—whether it is through water or air, the blade needs to remain at an optimal temperature to prevent warping or damage.

La composition of the blade also plays a role. Higher-quality diamond particles and a well-engineered bond will extend the blade’s life. Using a blade for the material it was designed for is key; each type of diamond blade has a specific bond that works best for certain materials, maximizing durability.

| Factor | Details |

|---|---|

| Bond Hardness | Softer for metal cutting |

| Diamond Quality | Higher quality lasts longer |

| Cooling (Water/Dry) | Wet cutting prolongs lifespan |

| Usage Frequency | Frequent use leads to faster wear |

| Proper Handling | Prevents overheating, warping |

What is Diamond Blade Segment Height and is it Important?

Have you ever wondered about those segments on a diamond blade? The segment height—those small blocks of diamonds along the edge—plays a crucial role.

Segment height refers to how much of the blade’s diamond edge is available to cut. Higher segments typically mean a longer blade lifespan, but not necessarily faster cutting. They impact how effectively the blade can cut before wearing down.

Segment Height in Action

UN higher segment height is better for tougher jobs since it allows the blade to last longer. The more diamond material present, the longer the blade will stay effective, as more of the cutting edge can be exposed over time. However, the segment height alone doesn’t guarantee a faster or cleaner cut. It’s more about how much cutting material is available, which helps maintain performance over an extended period.

In the context of cutting thin metal, segment height is not the most critical factor. For metal cutting, sharpness and appropriate teeth are more relevant than having a higher segment. Diamond blades with tall segments are advantageous for materials like concrete, where prolonged cutting sessions are required.

| Type de segments | Suitable Use Cases | Avantages |

|---|---|---|

| High Segment Height | Concrete, Stone Cutting | Longer blade lifespan |

| Low Segment Height | Tile, Ceramic | Smoother, cleaner cut |

Can You Cut a Porcelain Sink?

If you’re thinking about cutting a porcelain sink—yes, you can. Diamond blades are perfect for porcelain. These materials are challenging for traditional blades because of their brittle nature, which can lead to chipping and cracking. Using a diamond blade allows for a much cleaner cut.

Yes, a diamond blade can cut a porcelain sink. You’ll need a continuous rim blade for the cleanest edge. These blades are designed to keep the cut smooth, minimizing chipping, which is essential for ceramic or porcelain. Using water as a coolant is vital here, as it reduces friction, minimizes heat, and prevents cracks from forming in the porcelain.

Cutting a Porcelain Sink with a Diamond Blade

When cutting a porcelain sink, you need to consider a few key points:

- Mark Your Cut: Always mark the area you want to cut using a grease pencil or masking tape. This helps guide your cut and reduces errors.

- Use a Wet Saw: If possible, use a wet saw with a continuous rim diamond blade. The water cools the blade, reduces dust, and minimizes the risk of cracks and chips.

Step-by-Step Process for Cutting Porcelain

- Preparation: Secure the sink on a stable surface, ensuring it won’t move during cutting. Mark the line where you want to make the cut.

- Safety First: Wear goggles, gloves, and a dust mask to protect yourself from dust and debris.

- Coupe: Use a wet saw with a continuous rim blade, following the marked line carefully. Make sure to keep a slow, steady pace to prevent overheating and cracking.

- Finishing Touches: Once the cut is complete, use sandpaper or a diamond file to smooth the edges.

How to Sharpen a Diamond Saw Blade?

Believe it or not, sharpening a diamond blade is something you might need to do, especially if it seems like it’s lost its cutting edge. Here’s how.

To sharpen a diamond saw blade, cut into a material that’s abrasive—like a concrete block or a special sharpening stone. This process will expose new diamond particles and get your blade back in shape. Over time, the metal bond that holds the diamonds in place can become polished, reducing the blade’s ability to cut effectively. Sharpening helps remove this polished layer and expose fresh diamonds for better performance.

Steps to Sharpen a Diamond Blade

- Secure the Blade: Make sure the blade is mounted securely on your saw. Loose blades can lead to inaccuracies and potential safety hazards.

- Use Abrasive Material: Cut into something abrasive like a brick, cinder block, or grinding stone. This will help wear away the metal bond and expose new, sharp diamond particles.

- Make Several Cuts: Slowly pass through the abrasive material multiple times to sharpen the blade effectively. This process can take a few minutes, but it’s worth it for improved cutting performance.

When to Sharpen Your Diamond Blade

Knowing when to sharpen your diamond blade is crucial for maintaining efficient cuts. Signs that your blade needs sharpening include:

- Sluggish Cutting: If the blade takes noticeably longer to cut through materials.

- Glazed Appearance: The diamond edge appears shiny or polished.

- Burn Marks: The material being cut shows burn marks, indicating the blade is struggling.

By keeping your blade sharp, you’ll not only save time on your projects but also extend the life of the blade, ensuring clean, efficient cuts each time.

Conclusion

Diamond blades are not suitable for cutting metal—using them can be dangerous due to diamond particles potentially flying off. Always use the right tool for the job to ensure safety and efficiency. For any cutting job, choosing the appropriate blade is crucial for both performance and safety. Understanding your tools and their limitations helps ensure that every cut you make is clean, efficient, and above all, safe.