When working on DIY projects or professional construction, choosing the right tool can make all the difference. Auger bits and drill bits are both essential, but they serve different purposes. How do you know which one to use? Let’s break it down.

Auger bits are designed for drilling deep, clean holes in wood, while drill bits are more versatile and can be used on various materials like metal, concrete, and plastic. The key difference lies in their design and application.

Understanding the differences between auger bits and drill bits can save you time, money, and frustration. Let’s dive deeper into their unique features and uses.

What is The Difference Between an Auger Bit And a Drill Bit?

Choosing the wrong bit can lead to poor results1 or even damage your tools. Auger bits2 and drill bits may look similar, but they are designed for different tasks.

Auger bits have a helical screw tip that pulls the bit into the wood, making them ideal for deep, clean holes. Drill bits, on the other hand, come in various types and are suitable for multiple materials.

Key Differences in Design and Functionality

| Caractéristique | Auger Bit | Foret |

|---|---|---|

| Matériel | Primarily for wood | Wood, metal, concrete, plastic |

| Tip Design | Helical screw tip | Pointed or flat tip |

| Hole Depth | Deep holes | Shallow to medium holes |

| La rapidité | Slower due to pull mechanism | Faster for most materials |

Auger bits are perfect for woodworking projects3 that require precise, deep holes. Drill bits, however, are more versatile and can handle a range of materials. Knowing these differences helps you choose the right tool for the job.

Real-Life Applications of Auger Bits and Drill Bits

In my experience as a tool manufacturer, I’ve seen many cases where using the wrong bit caused unnecessary problems. For instance, a customer once tried to use an auger bit on a metal surface, which resulted in a damaged bit and a frustrated user. On the other hand, a wood drill bit used on concrete will quickly dull and fail to penetrate the surface. These examples highlight the importance of selecting the right bit for the material you’re working with.

How Do Auger Bits Work?

Ever wondered how auger bits create such clean holes in wood? Their unique design makes them stand out in the world of drilling tools.

Auger bits work by using a helical screw tip that pulls the bit into the wood, while the flutes remove debris. This creates smooth, precise holes without splintering.

The Mechanics Behind Auger Bits

- Pointe de vis: The helical tip acts like a screw, pulling the bit into the wood with minimal effort.

- Flûtes: These spiral grooves remove wood chips and debris, keeping the hole clean.

- En pointe: The sharp edges ensure precise cuts, reducing the risk of splintering.

Auger bits are ideal for projects like fabrication de meubles4, where clean, deep holes are essential. Their design ensures efficiency and precision, making them a favorite among woodworkers5.

Advantages of Using Auger Bits

- Efficiency: The screw tip reduces the effort needed to drill.

- Clean Holes: The flutes prevent debris buildup, ensuring a smooth finish.

- Polyvalence: Suitable for various wood types, from softwoods to hardwoods.

Common Mistakes When Using Auger Bits

- Using on Non-Wood Materials: Auger bits are designed for wood and will fail on harder materials.

- Incorrect Speed: Using too high a speed can cause overheating and damage the bit.

How to Choose the Right Wood Drill Bit?

Choosing the right wood drill bit can be overwhelming. With so many options available, how do you make the right choice?

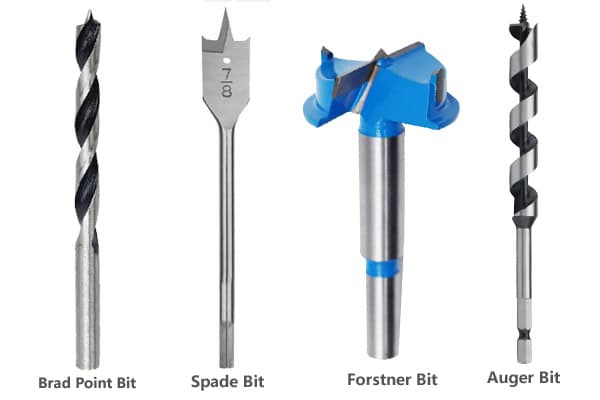

The right wood drill bit depends on the type of wood, hole size, and depth required. For softwoods, brad point bits are ideal, while spade bits are better for larger holes.

Factors to Consider When Selecting a Wood Drill Bit

| Type of Bit | Best Use |

|---|---|

| Mors Point Brad | Precision holes in softwoods |

| Spade Bit | Large, rough holes |

| Mors Forstner | Flat-bottomed holes |

| Auger Bit | Deep, clean holes in hardwoods |

For softwoods like pine, brad point bits6 provide clean, precise holes. Spade bits are great for rough work, while Mors Forstner7 are perfect for flat-bottomed holes. Auger bits, as mentioned earlier, excel in deep drilling.

Matching the Bit to the Project

- Precision Work: Use brad point bits for cabinetry and detailed woodworking.

- Large Holes: Spade bits are ideal for creating holes for wiring or plumbing.

- Flat Bottoms: Forstner bits are perfect for creating holes for hinges or dowels.

Tips for Maintaining Wood Drill Bits

- Affûtage: Regularly sharpen the bits to maintain their cutting efficiency.

- Nettoyage: Remove wood resin and debris after each use to prevent buildup.

- Storage: Store bits in a dry place to avoid rust and corrosion.

What Happens if I Use a Wood Drill Bit on a Concrete Wall?

Using the wrong drill bit can damage both the tool and the material. What happens if you use a wood drill bit on concrete?

Using a wood drill bit on concrete will likely dull the bit quickly, damage the wall, and produce poor results. Concrete requires specialized masonry bits designed to handle its hardness.

Why Specialization Matters

- Material Hardness: Concrete is much harder than wood, requiring stronger bits.

- Bit Design: Masonry bits have a carbide tip for durability and efficiency.

- Safety: Using the wrong bit can cause the drill to overheat or break.

To drill into concrete, always use a masonry bit8. Wood drill bits are not designed for such tasks and will fail to perform effectively.

Signs You’re Using the Wrong Bit

- Increased Effort: If drilling becomes excessively difficult, you might be using the wrong bit.

- Poor Hole Quality: Jagged edges or uneven holes indicate an incorrect bit.

- Bit Damage: Dulled or broken bits are a clear sign of mismatch.

Tips for Drilling Concrete

- Use a Hammer Drill: This tool is designed for masonry work and provides the necessary impact.

- Start Slow: Begin at a low speed to avoid overheating the bit.

- Apply Water: Cooling the bit with water can extend its life and improve performance.

Additional Considerations for Choosing Drill Bits

Material-Specific Bits

Different materials require specific types of drill bits. Here’s a quick guide:

| Matériel | Recommended Drill Bit |

|---|---|

| Bois | Brad point, spade, auger |

| Métal | Acier rapide (HSS) |

| Béton | Masonry bits with carbide tips |

| Plastique | Standard HSS or brad point |

Bit Coatings and Their Benefits

- Revêtement en titane: Adds durability and reduces friction.

- Cobalt Coating: Ideal for drilling through hard metals.

- Oxyde noir: Provides rust resistance and increased hardness.

Importance of Bit Maintenance

Regular maintenance ensures your drill bits last longer and perform better. Always:

- Clean bits after use.

- Sharpen dull bits.

- Store in a dry, organized case.

Conclusion

Understanding the differences between auger bits and drill bits ensures you choose the right tool for every project. Whether you’re drilling wood, metal, or concrete, the right bit makes all the difference. By matching the bit to the material and task, you can achieve professional results and extend the life of your tools.

-

Learn about the consequences of selecting the wrong drill bit and how it can affect your work quality and tool longevity. ↩

-

Explore this link to understand the specific applications and advantages of Auger bits in drilling tasks. ↩

-

Discover expert tips for woodworking projects to improve your skills and achieve better results. ↩

-

Learn about the best tools for furniture making, including how Auger bits can enhance your craftsmanship and efficiency. ↩

-

Discover the tools that professional woodworkers swear by, including the essential role of Auger bits in their projects. ↩

-

Explore this link to understand the advantages of brad point bits for achieving clean and precise holes in softwoods like pine. ↩

-

Discover the unique features of Forstner bits and how they can help you create flat-bottomed holes with precision. ↩

-

Understanding masonry bits is crucial for effective concrete drilling. This resource will provide detailed insights and usage tips. ↩