Finding the right HSS drill bits manufacturer has been a personal journey for me. I’ve learned a lot along the way and want to share my experience in simple, honest language that anyone can understand.

In this article, I share my personal insights and step-by-step strategies for finding a reliable HSS drill bits manufacturer. I discuss the vital role these bits play in the industry, what criteria to look for, the importance of quality control, and how to build lasting partnerships. Whether you’re new to the field or have been around for years, I hope this friendly guide feels like a chat with a trusted friend over a warm cup of coffee.

Let’s dive in and explore these key points step by step.

What is the Critical Role of HSS Drill Bits in Our Industry?

Every tool has its story, and HSS drill bits are no exception. I’ve seen firsthand how these bits can make or break a project. Their strength and precision are essential to many industrial processes, and understanding this role has changed the way I approach my work.

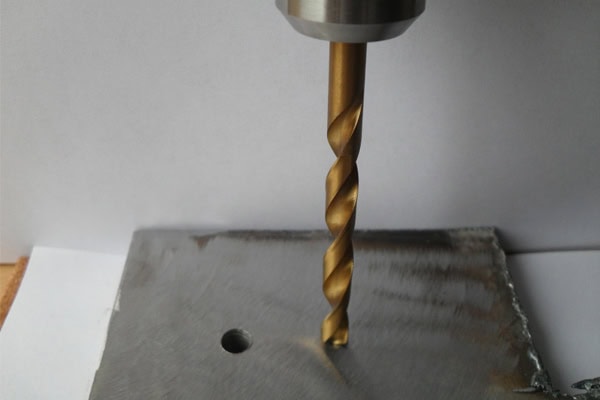

HSS drill bits are at the heart of many manufacturing and construction tasks. They provide durability and accuracy in drilling, which is crucial for everything from small repairs to large-scale production. In my experience, knowing exactly how these bits work and the value they bring helps me appreciate the technology behind every cut and hole, ensuring that I choose products that truly meet my needs.

When I first began working with HSS drill bits, I was fascinated by how a small tool could wield so much power in shaping materials1. Over time, I learned that these bits are not just another component in the manufacturing process—they are a cornerstone for efficiency and quality.

Durability and Precision

I remember a project where precision was non-negotiable. Using HSS drill bits allowed me to achieve the exact specifications needed, which not only improved the final product but also saved time and reduced waste. This experience taught me that durability and precision are the two pillars of any successful drilling operation.

Versatility in Application

Whether I’m working on metal, wood, iron or stainless steel2 materials, the versatility of HSS drill bits stands out. Their ability to adapt to different materials means that I don’t have to stock multiple specialized tools, which simplifies my workflow and cuts down on costs.

Efficiency and Cost-Effectiveness

In my early days, I often struggled with tools that wore out too quickly. Investing in high-quality HSS drill bits changed that. They have a longer lifespan and maintain sharpness, meaning fewer replacements and a smoother process overall.

Over the years, I’ve realized that the critical role of HSS drill bits is not just in their functionality but also in the confidence they bring. When I have the right tools, I can focus more on innovation and less on worrying about equipment failure. It’s a small decision that leads to big rewards in productivity and safety. The impact of a reliable drill bit can ripple through every stage of a project, highlighting the importance of selecting the right manufacturer in the first place.

How Can I Evaluate a Reliable HSS Drill Bits Manufacturer?

Choosing the right manufacturer isn’t always straightforward. I’ve had my share of trial and error, and today I want to share how I personally evaluate a manufacturer to ensure quality and reliability.

To evaluate a reliable HSS drill bits manufacturer, I focus on key criteria like product quality, consistency, and after-sales support. I look for companies that are transparent about their production methods, offer clear quality certifications, and maintain open communication. In my experience, a manufacturer who is willing to share their process and history is a sign of trustworthiness and commitment to excellence.

When I first began searching for a dependable manufacturer, I made a checklist of qualities that were non-negotiable for me. I was not just looking for competitive prices3; I needed a partner who could provide long-lasting performance and support. Here’s how I break down my evaluation process:

Research and Reviews

I start by scouring the internet for reviews, testimonials, and case studies. I value honest feedback from real users because it gives me insight into how the manufacturer handles issues and how consistent their product quality is over time.

Certifications and Standards

Quality certifications are a strong indicator of a manufacturer’s commitment to high standards. I always check if they have relevant ISO certifications or industry-specific approvals. It reassures me that their production processes meet rigorous standards.

Communication and Transparency

For me, the ability to communicate directly with the manufacturer is key. I appreciate companies that are open about their production process, share detailed product information, and respond promptly to inquiries. This transparency builds trust and gives me confidence in their offerings.

Cost vs. Value Analysis

Price is important, but it’s not the only factor. I like to compare cost against the durability and performance of the drill bits. Sometimes, paying a bit more upfront saves money in the long run by reducing replacements and maintenance costs.

Here’s a simple table I often use to compare manufacturers:

| Criteria | Importance | Notes |

|---|---|---|

| Product Quality | High | Look for consistency and durability |

| Certifications | High | ISO and industry-specific standards |

| Customer Service | Medium | Responsiveness and transparency matter |

| Cost vs. Value | High | Balance price with performance and longevity |

| Innovation and R&D | Medium | A focus on new technologies is a plus |

This table has helped me clarify what to expect and compare various options side-by-side. Each criterion reflects a part of the story behind a manufacturer’s reputation. When I find a company that checks all these boxes, I feel much more confident that I’m making a sound investment.

Personal Experience

One time, I worked with a manufacturer who was extremely detailed about their quality control process. They even invited me to see a short video of their production line, which solidified my decision. Experiences like these remind me that a little extra effort in evaluating options can lead to much smoother operations down the road.

By following these evaluation steps, I’ve learned to separate genuine, reliable manufacturers from those that overpromise and underdeliver. This personal checklist has not only saved me time and money but has also helped me build stronger, trust-based relationships with suppliers.

Why is Quality Control Vital in HSS Drill Bits Manufacturing?

Quality control4 isn’t just a process—it’s a commitment to excellence. I’ve witnessed firsthand the difference that stringent quality checks can make in the performance and reliability of HSS drill bits, and it’s a topic close to my heart.

Quality control in HSS drill bits manufacturing is crucial because it ensures that every bit meets strict standards of precision and durability. In my experience, the best manufacturers invest heavily in quality control, testing every product thoroughly before it reaches the market. This attention to detail minimizes the risk of tool failure and improves overall safety and efficiency on the job.

I remember a time when I faced unexpected tool failures mid-project. It was a stressful period, and I quickly learned that poor quality control could lead to delays, increased costs, and even safety hazards. Since then, I’ve made quality control a top priority when selecting a manufacturer.

The Testing Process

I always ask manufacturers about their testing processes. Do they perform stress tests, measure hardness, and check for uniformity? Knowing that each bit is tested multiple times gives me peace of mind. I appreciate manufacturers who explain their methods in simple terms.

Consistency Matters

One of the biggest benefits of strong quality control is consistency. I rely on my tools to perform exactly as expected every time. Inconsistent quality not only disrupts workflow but can also result in costly errors. That’s why I value manufacturers who document every stage of production and testing.

Safety and Reliability

For me, safety is paramount. I’ve seen how a subpar drill bit can lead to dangerous situations. Robust quality control ensures that every product is safe to use and meets industry standards. It’s not just about performance—it’s about protecting everyone on the job.

Continuous Improvement

Good quality control is an ongoing effort. I admire manufacturers who are committed to continuous improvement, regularly updating their processes based on feedback and technological advances. This proactive approach often leads to innovations that benefit everyone involved.

In one project, I worked with a company that provided detailed quality reports with each order. These reports included data on material composition, test results, and even notes on potential improvements. This level of transparency was reassuring and allowed me to plan my projects with confidence.

Detailed Insights

- Process Documentation: I look for companies that keep thorough records. It shows they care about accountability.

- Employee Training: Well-trained staff are the backbone of quality control.

- Advanced Equipment: Modern testing equipment can catch issues that older methods might miss.

By choosing a manufacturer with a robust quality control system, I’ve found that I face fewer surprises on the job. It builds trust and lets me focus on my craft, knowing that each drill bit will perform as promised. This commitment to quality is not just a standard—it’s a promise of safety, efficiency5, and reliability that I value immensely.

How Do I Build Long-term Partnerships for Sustainable Growth in the Industry?

Over the years, I’ve learned that the relationships I build with manufacturers can be as important as the products themselves. Building long-term partnerships has helped me grow and maintain a steady flow of reliable tools.

Long-term partnerships in the HSS drill bits industry are built on trust, open communication, and mutual benefit. I believe that by working closely with manufacturers, sharing honest feedback, and investing time in understanding their processes, both parties can achieve sustainable growth. This approach has allowed me to secure better pricing, priority support, and even custom solutions tailored to my needs.

I still remember my early days, when every new supplier felt like a gamble. With time, I realized that the key to success wasn’t in switching suppliers frequently, but in cultivating relationships that could evolve over time. Here’s how I approach building these lasting partnerships:

Open and Honest Communication

I make it a point to share my needs and challenges openly with my manufacturers. Whether it’s discussing delivery timelines, product specifications, or even unexpected issues, I believe that honesty sets the foundation for trust. When I’ve seen a manufacturer respond with genuine concern and proactive solutions, it has always strengthened our bond.

Mutual Growth and Flexibility

In my journey, I’ve come to value partnerships where both parties are invested in each other’s success. I’m not just a customer—I’m a collaborator. I share market insights, provide feedback on product performance, and even suggest improvements. This two-way street often leads to innovations that benefit us both.

For example, I once suggested a minor tweak in the drill bit design based on feedback from my field team. The manufacturer not only adopted the change but also recognized our input by offering a customized product line. This kind of flexibility has been key to my long-term growth.

Regular Check-ins and Updates

Keeping the lines of communication open is crucial. I schedule regular calls or meetings to discuss upcoming projects, review past performance, and plan for future demands. These check-ins have helped me avoid miscommunications and adapt quickly when market conditions change6.

Trust and Reliability

Trust isn’t built overnight. It comes from consistent performance and mutual respect. I choose manufacturers who honor their commitments, maintain quality, and show a genuine interest in my success. When both sides feel valued, the partnership grows stronger, fostering innovation and stability.

Keys to a Strong Partnership

- Transparency: Sharing both successes and challenges helps build trust.

- Collaboration: Working together on solutions makes all the difference.

- Respect: Valuing each other’s expertise leads to better outcomes.

Below is a simple table that outlines the benefits I’ve experienced from long-term partnerships:

| Aspect | Benefit | My Experience |

|---|---|---|

| Open Communication | Fewer misunderstandings, faster resolutions | Regular updates keep us on the same page |

| Flexibility | Custom solutions and improved products | Mutual adjustments have led to innovation |

| Reliability | Consistent quality and timely deliveries | Trust grows with every successful order |

| Mutual Growth | Shared market insights and continuous improvement | Our collaboration has opened new opportunities |

This table is a quick snapshot of how strong partnerships translate into tangible benefits. For me, it’s about building a network of trusted partners who are as committed to excellence as I am. When you invest in these relationships, you’re not just buying products—you’re securing a future of sustainable growth, innovation, and shared success.

Every conversation, every feedback loop, and every small improvement makes these relationships more valuable. In the long run, it’s these partnerships that help me stay ahead of industry trends and overcome challenges with confidence.

Conclusion

Choosing the right HSS drill bits manufacturer has transformed my work and boosted my confidence. By focusing on quality, clear communication, and mutual growth, I’ve built lasting partnerships that support my journey every day.

-

Linking this term gives readers deeper insights into the material shaping process and the role that drill bits play, especially in precision work. ↩

-

Linking to stainless steel materials helps users understand the hss drill bit usage. ↩

-

Exploring competitive pricing strategies can help readers understand the trade-offs and strategies involved in cost-effective manufacturing. ↩

-

This query helps users explore foundational strategies in quality control, ensuring they understand its importance in achieving consistent product excellence. ↩

-

This link provides users with an understanding of why these standards are essential, emphasizing their impact on overall product quality and operational trust. ↩

-

Providing this link directs users to information on adapting to market volatility, ensuring they have strategies to remain competitive during shifts in the market. ↩