Are your drill bits crumbling before the job’s even halfway done? It’s time to find a manufacturer you can trust.

Choosing the right masonry drill bit manufacturer ensures you get quality tools that last, improving efficiency and reducing costs. I’ll show you how to find them.

Ready to stop wasting money on bits that break too soon? Let’s get started.

Understanding the Essentials: What Makes a High-Quality Masonry Drill Bit?

Ever wondered why some drill bits seem to breeze through brick while others struggle and fail? It all comes down to quality.

High-quality masonry drill bits have tough carbide tips, durable shanks, and efficient flutes to remove debris, ensuring clean, precise holes. While often used interchangeably with "concrete drill bits", remember concrete drill bits are generally tougher and feature a harder tungsten carbide tip for concrete. I’ll explain what to look for.

Material Matters

The materials used in a masonry drill bit determine its strength and lifespan.

| Material | Descripción |

|---|---|

| Carburo de tungsteno | This is what the tip is made of. It’s super hard, so it can drill into tough stuff like brick, concrete, and stone without wearing down too fast. The better the quality of the carbide, the longer the bit will last. For concrete drill bits, look for a harder, more robust tungsten carbide. |

Design and Construction

Besides the materials, how a drill bit is made also affects its quality.

| Rasgo | Descripción |

|---|---|

| Carbide Tip | The way the carbide tip is attached to the bit is important. It needs to be strong enough to withstand the force of drilling. Some bits have a solid carbide head with multiple cutting edges for faster drilling. Concrete drill bits often have a more reinforced tip design. |

| Flute Design | The flutes are the grooves that run along the bit. They help remove dust and debris from the hole as you drill. Wider flutes can remove more material, which keeps the bit cooler and makes drilling easier. |

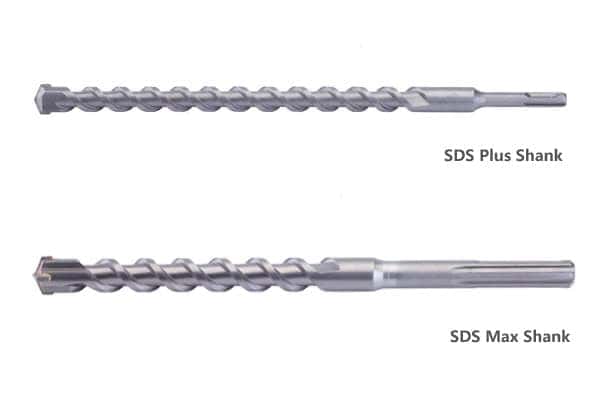

| Tipo de vástago | The shank is the part that fits into the drill. Make sure the shank is compatible with your drill (e.g., standard, SDS, or hammer drill). Some shanks have a hex design for a better grip. |

I’ve found that bits with well-designed flutes make a huge difference, especially when drilling deep holes. They clear out the dust and prevent the bit from getting stuck. Also, using the right type of shank for your drill is crucial for safety and efficiency.

Features that enhance performance

Some extra features can make a big difference in how well a drill bit works.

| Rasgo | Descripción |

|---|---|

| Coatings | Some bits have coatings like black oxide or titanium-based coatings. These can reduce friction, improve lubricity, and provide some corrosion resistance. However, the quality of the carbide tip is more important than any coating. |

| Wear Marks | Some bits have wear marks that show you when the bit is no longer creating accurate holes. This is really helpful for anchor installations where precision is key. |

| Optimized for Cordless | Some drill bits are designed to use less energy, which extends the battery life of your cordless power tools. This can increase productivity, especially on big jobs. |

Recently, I tested some bits with wear marks, and they really helped me maintain accuracy. It’s a small feature, but it saved me a lot of time and frustration. When you’re choosing a broca para albañilería1, pay attention to these essential features to ensure you’re getting a tool that will perform well and last. Consider a concrete drill bit if you’re primarily working with tougher concrete.

Key Factors to Consider When Choosing a Masonry Drill Bit Manufacturer

Finding a reliable manufacturer is crucial for consistent quality and supply.

When choosing a manufacturer, consider their experience, certifications, customization options, and quality control processes to ensure you get reliable, high-performance drill bits. Ensure they can provide the specific type you need, be it a standard masonry bit or a heavy-duty concrete bit. I’ll walk you through it.

Assessing Manufacturer Capabilities

It’s important to know what a manufacturer can do before you decide to work with them.

| Capability | Descripción |

|---|---|

| Experience | Look for manufacturers with a long history in the industry. They’re more likely to have the expertise and knowledge to produce high-quality drill bits. |

| Certifications | Check if the manufacturer has certifications like ISO and CE. These show they meet international standards for quality and safety. |

| Customization | If you need custom sizes, materials, or branding, choose a manufacturer that offers these options. This is especially important if you want to create a unique product line. |

| Capacidad de producción | Make sure the manufacturer can produce enough drill bits to meet your needs. Ask about their production capacity and lead times. |

| R&D Capabilities | Does the manufacturer invest in research and development? A manufacturer that’s always innovating is more likely to offer the latest and best technology in their drill bits. |

Evaluating Quality Control Processes

A manufacturer’s quality control processes are key to ensuring consistent product quality.

| Proceso | Descripción |

|---|---|

| Material Inspection | The manufacturer should inspect all raw materials to make sure they meet quality standards. This includes checking the hardness and composition of the carbide tips and steel shanks. |

| In-Process Inspection | Quality checks should be done throughout the manufacturing process to catch any defects early on. This can include checking the dimensions of the bits, the quality of the welds, and the sharpness of the cutting edges. |

| Final Inspection | Before the drill bits are packaged, they should be inspected again to make sure they meet all quality requirements. This can include testing the bits on different materials to see how well they perform. |

| Statistical Process Control (SPC) | A good manufacturer will use SPC to monitor and control the manufacturing process. This involves collecting data on various aspects of the process and using it to identify and correct any problems. |

I always emphasize the importance of quality control to my team. It’s not enough to just make drill bits; we have to make sure they’re the best they can be. By implementing strict quality control2 processes, we can reduce the risk of defects3 and ensure that our customers are happy with our products.

Communication and Support

Good communication and support from a manufacturer can make a big difference in your overall experience.

| Aspect | Descripción |

|---|---|

| Responsiveness | The manufacturer should be responsive to your inquiries and provide timely updates on your orders. This is especially important when you have urgent needs or questions. |

| Technical Support | The manufacturer should have technical experts who can answer your questions about their products and help you choose the right drill bits for your application. |

| Customer Service | The manufacturer should have a dedicated customer service team that can handle any issues or complaints you may have. They should be willing to go the extra mile to make sure you’re satisfied. |

| Language Support | If you’re working with a manufacturer in another country, make sure they have staff who can communicate with you in your preferred language. |

I’ve learned that good communication is key to building strong relationships with my customers. I always make sure my team is responsive and helpful, and I encourage them to go the extra mile to solve any problems. By providing excellent support, we can build trust and loyalty with our customers.

Sourcing Strategies: Where to Find Trustworthy Masonry Drill Bit Suppliers

Finding the right supplier can feel like searching for a needle in a haystack.

Trustworthy suppliers can be found through online marketplaces, industry trade shows, and referrals, but thorough vetting is essential to ensure quality and reliability. Be clear about your needs – are you looking for standard masonry bits or heavy-duty concrete drill bits? Here’s how.

Online Marketplaces

Online marketplaces can be a great place to find a wide range of suppliers.

| Marketplace | Descripción |

|---|---|

| alibaba | This is one of the largest online marketplaces in the world, with a huge selection of suppliers from China and other countries. You can find drill bit manufacturers offering a wide range of products at competitive prices. |

| Industry B2B platforms | Consider leveraging industry-specific B2B platforms to find manufacturers. These platforms often have more specialized listings and can provide more detailed information about the suppliers. |

| Amazonas | While it’s known for retail, Amazon also has a section for business-to-business (B2B) sales. You can find drill bit suppliers offering smaller quantities, which can be useful for testing the waters before committing to a larger order. |

I have my own store on Alibaba, and it’s helped me connect with customers all over the world. But I always tell people to do their research4 before choosing a supplier. Check their ratings, read reviews5, and ask for samples before placing a big order.

Industry Trade Shows

Trade shows are a great way to meet suppliers in person and see their products firsthand.

| Trade Show | Descripción |

|---|---|

| International Hardware Fair | This is one of the largest hardware trade shows in the world, held in Cologne, Germany. You can find drill bit manufacturers from all over the world showcasing their latest products and technologies. |

| National Hardware Show | This trade show is held in Las Vegas, USA, and features a wide range of hardware products, including drill bits. It’s a good place to meet suppliers from North America and learn about the latest trends in the industry. |

| Canton Fair | This is a huge trade show held in Guangzhou, China. It covers a wide range of products, including hardware and tools. It’s a good place to find Chinese drill bit manufacturers and negotiate prices. |

I love going to trade shows because I get to meet other professionals in the industry and see what’s new. It’s also a great way to build relationships with potential suppliers and customers. Plus, you can often get special deals and discounts at trade shows.

Referrals and Recommendations

Getting referrals from trusted sources can help you find reliable suppliers.

| Source | Descripción |

|---|---|

| Industry Peers | Talk to other people in your industry and ask them for recommendations. They may have worked with suppliers who offer high-quality drill bits at competitive prices. |

| Professional Associations | Join professional associations related to the hardware or construction industry. These associations often have directories of suppliers and can provide valuable insights and recommendations. |

| Online Forums | Check online forums and discussion groups related to hardware and tools. People often share their experiences with different suppliers and can provide valuable feedback. |

When I was starting out, I got a lot of help from other business owners in my network. They shared their experiences and gave me valuable advice on finding reliable suppliers. Don’t be afraid to ask for help – it can save you a lot of time and money in the long run.

Ensuring Consistency: Quality Control and Supplier Verification Processes

Even after finding a potential supplier, you need to make sure they can consistently deliver quality products.

Verify suppliers through audits, certifications, and testing to ensure consistent quality and compliance with standards, building a reliable supply chain. Make sure to test them with the materials you plan to use them on – brick, stone, or concrete. Here’s how to do it.

Conducting Supplier Audits

Audits help you assess a supplier’s capabilities and quality control processes.

| Audit Type | Descripción |

|---|---|

| On-Site Audits | Visit the supplier’s factory to see their production facilities, equipment, and quality control processes firsthand. This allows you to assess their capabilities and identify any potential issues. |

| Desk Audits | Review the supplier’s documents and records to assess their quality management system, certifications, and compliance with standards. This can be done remotely, which saves time and money. |

| Third-Party Audits | Hire a third-party auditing firm to conduct an independent assessment of the supplier’s capabilities and quality control processes. This can provide an unbiased view and help you identify any potential risks. |

I always recommend doing on-site audits, if possible. It’s the best way to get a feel for a supplier’s operations and see if they’re really committed to quality. I also work with third-party auditors6 to get an unbiased assessment7 of my own.

Verifying Certifications and Compliance

Certifications show that a supplier meets certain standards for quality, safety, and environmental responsibility.

| Certificación | Descripción |

|---|---|

| ISO 9001 | This is an international standard for quality management systems. It shows that the supplier has a well-defined system for ensuring consistent product quality and customer satisfaction. |

| CE Marking | This is a European Union mark that shows the product meets certain safety, health, and environmental requirements. It’s required for products sold in the EU. |

Implementing Product Testing Protocols

Testing helps you verify that the drill bits meet your performance requirements.

| Testing Type | Descripción |

|---|---|

| In-House Testing | Conduct your own tests on the drill bits to see how well they perform in different materials. This can include testing their drilling speed, durability, and accuracy. |

| Third-Party Testing | Hire a third-party testing lab to conduct independent tests on the drill bits. This can provide an unbiased assessment of their performance and help you identify any potential issues. |

| Field Testing | Give the drill bits to your customers or employees and ask them to use them in real-world applications. This can provide valuable feedback on their performance and identify any potential problems that may not be apparent in lab tests. |

Conclusión

Finding a reliable masonry drill bit manufacturer requires careful consideration of quality, capabilities, and verification processes. Understanding the difference between masonry and concrete drill bits will help you choose wisely.

-

Understanding the key features of masonry drill bits can help you choose the right tool for your projects, ensuring efficiency and durability. ↩

-

Exploring best practices in quality control can help enhance your processes and ensure product excellence. ↩

-

Understanding strategies to minimize defects can lead to higher customer satisfaction and product reliability. ↩

-

Understanding the significance of research can help you make informed decisions when selecting suppliers, ensuring quality and reliability. ↩

-

Learning to read reviews effectively can provide insights into supplier reliability and product quality, enhancing your buying experience. ↩

-

This link will help you understand the role of third-party auditors in providing unbiased evaluations and identifying improvement areas. ↩

-

Discover the importance of unbiased assessments in ensuring quality and operational excellence in manufacturing. ↩