Diamond Grinding Wheel

- Your Best Reliable Diamond Grinding Wheel Suppliers -Tenyu Tools Offer Industrial Quality

- You can get consistent quality of the diamond grinding wheel.

- You are cooperating with the best diamond grinding wheel in China,

- Tenyu Tools can provide any maximum orders for your business.

- You will not see any defects on our diamond grinding wheel.

- You can get our experienced diamond grinding wheel technology.

- Send your inquiry to custom your diamond grinding wheel now.

Get Tenyu Tools of Diamond Grinding Wheel to Make Your Business More Prosperous

Tenyu Tools is a professional diamond grinding wheel supplier

As a diamond grinding wheel supplier, we can produce a diamond grinding wheel, industrial grinding wheel, and more.

That’s why we can offer you a high-quality diamond grinding wheel at a competitive price.

Tenyu Tools is the No.1 provider of diamond grinding wheels fit for your grinding wheel business and any related wholesale business. We have all the types of diamond grinding wheels that may offer to our clients.

In Tenyu Tools, we only used high-grade materials in manufacturing our diamond grinding wheels, We always make sure that all of our diamond grinding wheels over standard quality.

Tenyu Tools is a professional supplier of diamond grinding wheels in China. We are featured for our great quality products and outstanding services to our valued clients

Tenyu Tools custom industrial diamond grinding wheels in order for you to choose the industrial quality to satisfy your different customers, that you may need to complete your project with a professional diamond grinding wheels supplier.

Diamond grinding wheels are widely used in a lot of industrial.

If you need Diamond grinding wheels, Tenyu Tools offering its best Diamond to manufacture industrial diamond grinding wheels. absolutely has a perfect quality.

Industrial diamond grinding wheels in Tenyu Tools are safe and meet the highest standard of customer evaluation. If you are in need of diamond grinding wheels for your business, check on Tenyu Tools. you can get the best diamond grinding wheels supplier.

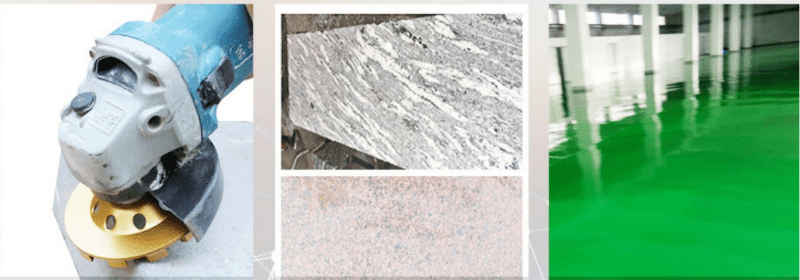

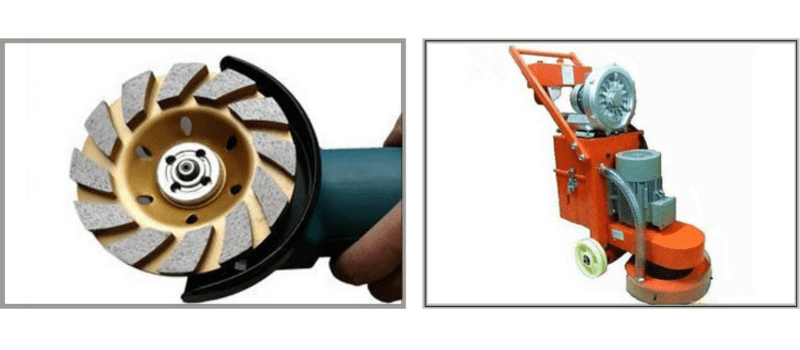

- Manufacturing Machine for Diamond Grinding Wheel

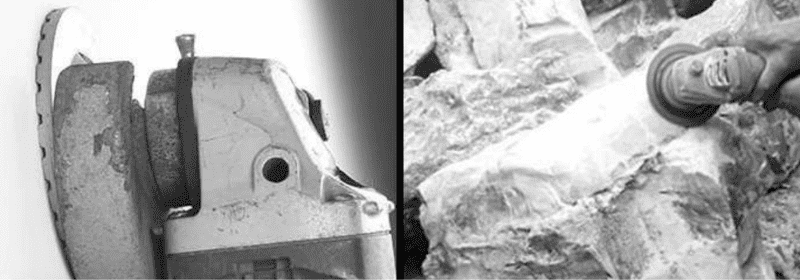

- Diamond Grinding Wheel Using

Tenyu Tools: Your Leading Diamond Grinding Wheels Supplier

Tenyu Tools is Located in the industrial town-Houxiang Town, We are committed to providing you with a solution for diamond grinding wheels.

Tenyu Tools extend always in showing their excellent services for their customers. As a fast-growing supplier providing diamond grinding wheels, you can choose any of our diamond grinding wheels that you may need for the quick success of your business.

For many years, Tenyu Tools is serving customers with our ability and experience in the supplier industrial. We offer the professional industry of diamond grinding wheels products and diamond grinding wheels related commodities.

Send us an inquiry now, we can sure to answer you immediately for diamond grinding wheels.

Custom Industrial Diamond Grinding Wheel to Skyrocket Your Business

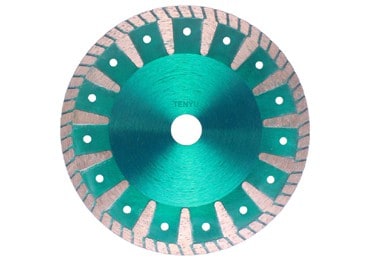

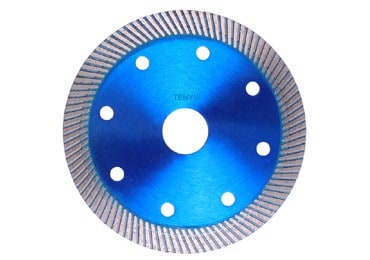

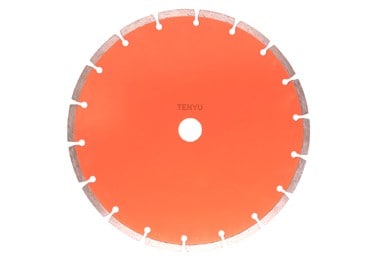

Tenyu Tools offers a variety of colors and thicknesses and quality grades of diamond grinding wheels sheet excellent marble floor and concrete floor applications without compromising the hardness and durability.

The Ultimate FAQ Diamond Grinding Wheel:

Tenyu Tool is a leading global manufacturer of diamond grinding wheels. We understand that you may have some questions about diamond grinding wheels. Here, check out some commonly asked questions and their answers. Check them out below;

1.What can I use diamond grinding wheels for?

Diamond grinding wheels are grinding wheels that have industrial diamonds attached to them to make grinding easier. Diamond grinding wheels are best used to grind extremely hard materials like concrete, gemstones, or carbide.

2.How long can I use my diamond grinding wheel?

The recommended timeframe to use your diamond grinding wheel is two years from the date of manufacture. This duration is dependent on if you have used and stored the grinding wheels under ideal conditions. This is why all diamond wheel suppliers and manufacturers like Tenyu Tool gives tips on how to care for and store your diamond grinding wheel.

3.What is the suitable grit for a diamond grinding wheel for concrete?

The best diamond grinding wheel for concrete should have a maximum coarseness of 30 to 40 grit.

4.Do diamond grinding wheels explode? If yes, why?

In some cases, although rare, diamond grinding wheels do explode, but this does not often happen as a result of the wheel’s quality. Explosions happen as a result of too much heat generated during the grinding process. When grinding, the wheel generates a lot of heat, which expands it and embeds foreign materials into the stone. This results in a differential rate of thermal expansion between the diamond and the foreign materials and ultimately leads to an explosion. Diamond grinding wheels can explode in any situation, even if it is industrial diamond grinding wheels.

5.What are the types of grinding I can carry out with a diamond grinding wheel?

There are five types of grinding that you can execute with a diamond grinding wheel. They are cylindrical grinding, surface grinding, centerless grinding, special grinding, and internal grinding.

6.Can I dress a diamond grinding wheel?

Yes, you can dress a diamond grinding wheel.

7.What does dressing a wheel mean?

When you use your diamond grinding wheel to a point, it begins to lose its sharpness and becomes dull. The dressing is the process of sharpening the cutting edges and surface of the wheel using a wheel dresser. You can get a wheel dresser from your diamond wheel supplier.

8.How often:

Tenyu Tool is a leading global manufacturer of diamond grinding wheels. We understand that you may have some questions about diamond grinding wheels. Here, check out some commonly asked questions and their answers. Check them out below;

1.What can I use diamond grinding wheels for?

Diamond grinding wheels are grinding wheels that have industrial diamonds attached to them to make grinding easier. Diamond grinding wheels are best used to grind extremely hard materials like concrete, gemstones, or carbide.

2.How long can I use my diamond grinding wheel?

The recommended timeframe to use your diamond grinding wheel is two years from the date of manufacture. This duration is dependent on if you have used and stored the grinding wheels under ideal conditions. This is why all diamond wheel suppliers and manufacturers like Tenyu Tool gives tips on how to care for and store your diamond grinding wheel.

3.What is the suitable grit for a diamond grinding wheel for concrete?

The best diamond grinding wheel for concrete should have a maximum coarseness of 30 to 40 grit.

4.Do diamond grinding wheels explode? If yes, why?

In some cases, although rare, diamond grinding wheels do explode, but this does not often happen as a result of the wheel’s quality. Explosions happen as a result of too much heat generated during the grinding process. When grinding, the wheel generates a lot of heat, which expands it and embeds foreign materials into the stone. This results in a differential rate of thermal expansion between the diamond and the foreign materials and ultimately leads to an explosion. Diamond grinding wheels can explode in any situation, even if it is industrial diamond grinding wheels.

5.What are the types of grinding I can carry out with a diamond grinding wheel?

There are five types of grinding that you can execute with a diamond grinding wheel. They are cylindrical grinding, surface grinding, centerless grinding, special grinding, and internal grinding.

6.Can I dress a diamond grinding wheel?

Yes, you can dress a diamond grinding wheel.

7.What does dressing a wheel mean?

When you use your diamond grinding wheel to a point, it begins to lose its sharpness and becomes dull. The dressing is the process of sharpening the cutting edges and surface of the wheel using a wheel dresser. You can get a wheel dresser from your diamond wheel supplier.

8.How often should I dress my grinding wheel?

Dressing your diamond grinding wheel at least once per day is a good rule of thumb.

9.When is the best time to dress my diamond grinding wheel?

Your diamond grinding wheel has specific materials that you should use it to grind. If someone uses the wrong material on it, you have to dress the grinding wheel. Always inspect your wheels before using them to avoid problems.

10.What tool is used to dress a grinding wheel?

There is a grinding dresser specifically designed for trimming or dressing the surface of your grinding wheel.

11.What is the method of making diamond grinding wheels?

When making diamond grinding wheels, diamond grinding wheels manufacturers use the hot pressing method. This method directly sinters the diamond segments in molds using a dedicated sintering press machine under pressure. The diamond segments are then fixed or connected to the body of the grinding wheel using a high-frequency welding method, mechanical mosaic, or laser welding.

12.In grinding wheels, what does a grade mean?

Grade refers to how hard the bond holds the abrasive grains or cutting points of your diamond grinding wheels. Grade does not in any way refer to how hard the abrasive grains are.

13.Can I use a diamond wheel to cut steel?

No, you cannot. Your diamond grinding is designed for grinding materials like plastic, carbide, concrete, and other synthetic materials.

14.Why you need to import the Diamond Grinding Wheel from Tenyu Tools?

Where do the grinding wheels come from? Knowing whether your diamond grinding wheels manufacturer makes the wheels themselves or gets them from another place is another important thing you must know.

Getting answers to these questions before buying will save you a lot of time. Diamond grinding wheels suppliers offer various products from different brands. You have to make sure you choose a supplier that gets its products from Tenyu Tool so you can be safe.

15.What are the characteristics of cutting wheels generally?

Some of the characteristics to consider in cutting wheels include the following

- Size of grain: This determines how coarse the abrasive is going to be.

- Grain spacing: This points to the wheel’s density.

- Material: this refers to what the abrasive itself is made from, e.g., silicon carbide, diamond, ceramic, aluminum oxide, or cubic boron nitride.

- Wheel Grade: This gives a pointer to how strongly or weakly the bond holds the abrasive.

- Bond Type: This can be made from a variety of materials, and it has an effect on wheel speeds, finish, and coolant.

What are Diamond Grinding Wheels Used for?

Diamond grinding wheels as the name suggests, are bound with diamonds on the periphery and are used for grinding extremely hard applications such as carbide cutting, gemstones and concrete cutting etc. This is the reason they are also known as super-abrasives.

Can You Dress a Diamond Grinding Wheel?

Yes, a diamond grinding wheel can indeed be dressed. If you want to dress the same, you will need to select a dressing stick with one/two grit sizes finer than the abrasive on the diamond wheel.

Make sure you cut off the coolant pump before you turn on the machine. Now, once switched on, allow the machine to reach full RPM and then turn off the spindle motor.

What are the Features of Diamond Grinding Wheels?

Diamond Grinding wheels have high hardness characteristics along with high thermal conductivity and the ability to provide high-efficiency machining.

Another major advantage of industrial diamond grinding wheels is you can reduce the processing cost in case of mass production applications.

Diamond Wheel Suppliers nowadays, have started to make customized diamond grinding wheels based on what a customer’s requirements are for an application.

Can I Use a Diamond Wheel on Steels?

Diamond Grinding Wheels are specifically used for grinding carbide, plastics, and other synthetic materials. It is advised not to use it on steel materials.

Can I Customize a Diamond Grinding Wheel from a Diamond Wheel Supplier?

Well, a majority of suppliers have pre-set the specifications of the diamond grinding wheels as per International standards, however, if you have specific requirements and the supplier has a provision to supply customized wheels, you can indeed customize the wheel as per your requirements. This will also let you have the best value for your money and have the confidence in dealing with machining tasks.

What are the Components of a Diamond Grinding Wheel?

You must have heard of this from many industrial diamond grinding wheel suppliers, and they stress it too, that diamond grinding wheels have three main components. These are the plate, the solder and the segments.

Now, to understand how these are bound together, you must know that the small blocks of diamond material called segments are attached to the spinning wheel known as a plate or cup using a product called solder.

How do I Choose a Diamond Grinding Wheel for Concrete?

There is a lot of points to be considered when looking to buy a diamond grinding wheel. The process of selection entails selecting the right category of diamond cup wheel, understanding the hardness of the surface which you are going to process, identifying the right abrasive components, selecting the right grit size, understanding and then selecting different diamond cup wheel shapes, selecting the right bond type, and checking if the selected wheel meets your requirements or not, and lots more.

While you can easily purchase a diamond grinding wheel online or going to the market, no diamond grinding wheels supplier would give you the liberty of customizing the specifications according to your choice.

Thus, selecting the best and customized industrial diamond grinding wheels from Tenyu Tools is the smartest choice you’ll ever make.

Getting a diamond grinding wheel will do you a lot of good when you need to cut through some materials. Getting it from Tenyu Tools is an even wiser decision that you will come to be thankful for in the future. You need a diamond grinding wheel supplier that gives you maximum guarantee before and after the sales. Contact us today at Tenyu Tool to get a quote on your diamond grinding wheel.

The Top 10 Secrets About Diamond Grinding Wheels and How to Get the Best Reliable Diamond Grinding Wheels Suppliers

Are you looking for quality diamond grinding wheels that are affordable, efficient, and durable? We got you covered. By using advanced equipment and highly trained personnel, we are able to manufacture high quality industrial grinding wheels made from pure diamond and export across the globe at competitive rates.

However, before we cover the process of importing diamond grinding wheels, it’s important to discuss a number of things that are related to diamond grinding wheels.

What is diamond grinding wheels?

Simply put, a diamond grinding wheel is used to grind abrasive building materials such as marble, granite, and concrete. It is strongly attached to concrete grinders and fastened before the grinding process starts.

The diamond grinding wheels are available in different sizes and specifications to suit different application requirements or projects. For example, grinding wheels that have large diamond segments are ideal for heavy workloads such as grinding stone and concrete. On the other hand, grinding wheels that have small segments of the diamond as used for less intensive projects such as removing wallpapers, glues, paints, epoxy, and any other surface coating.

It is also important to note that the diamond segments in the diamonds have varying grits, bonds, diamond quality, and concentration. If the material you intend to grind is hard, you should use a diamond grinding wheel whose bond is softer. If the material is soft, use a wheel that has a hard bond.

If you intend to do a coarse grinding project, choose a wheel whose bond is soft but the quality of the diamond should be high because the high friction will make the diamond blunt faster and easier if the quality of the diamond is low.

For fine grinding projects such as polishing, go for diamond grinding wheels whose bond is harder and the quality of the diamonds is low. In this case, the diamonds will last longer since there is not much friction between them and the surface. In addition, diamond segments with a hard bond will come in hardy to promote precision and achievement of fine results.

Ideally, diamond grit ranges between 80 and 120 grit, and the grinding requirements should help you to know the ideal specifications of the diamond grinding wheel you should buy.

Primary Factors That You Should Consider When Shopping for Diamond Grinding Wheels

Needless to say, the success of your project is dependent on the type of diamond grinding wheel that you use. Here is a detailed overview of the various factors that you should put into consideration when shopping for a diamond grinding wheel.

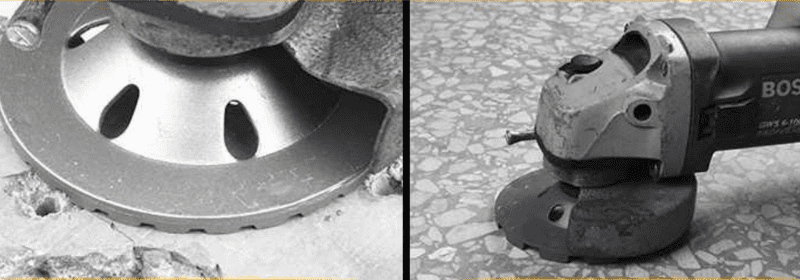

The Components of the Wheel

A diamond grinding wheel has three main parts. The small sections of the diamond material are commonly referred to as segments and are attached to the spinning wheel also referred to as the plate or. The solder is used to attach the diamond segments to the wheel.

So, the three main components of a diamond grinding wheel are:

- Cup

- Segments

- Solder

As from the different manufacturers will vary as some companies add vents or holes to facilitate easy air movement. The large plates (175 mm and beyond) need to be balanced by getting rid/drilling a small percentage of material from the plate surface to enhance its functionalism.

Each plate has diamond segments that are attached to them by using solder at very high temperatures and in a controlled environment. Grinding is done by the segments and that is why they are the first to get worn out. If worn out, you will need to replace the wheel with a new one.

Important Aspects of Diamond Grinding Wheel You Should Know?

The four main aspects of a diamond grinding wheel that you should know are:

- Grit

- Bond

- Surface Area

- Segment Shape

Let us shift gears and look at each of these fundamentals so that you can make an informed decision when placing your order.

Surface Area

The level or degree of speed or aggression is dependent on the cumulative surface area of all the diamond segments in the grinding wheel. You can easily calculate this by measuring the cross-sectional area of each diamond segment then multiply by the number of segments in the wheel.

As any expert will tell you, the larger the surface area, the slower and less aggressive the wheel will be when you turn the grinder on. The vice versa is also true, the smaller the surface area, the faster and more aggressive the wheel will be.

More scratching of the surface will be seen as the surface area of the segments drops. If you don’t want any scratches on the surface, it is recommended to use aggressive diamond grinding wheels.

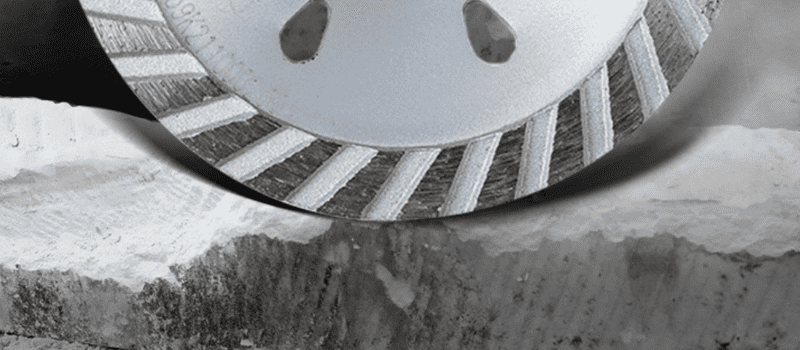

The Diamond Segment Shape

Unknown to most people is that the shape of the diamond segment has a direct impact on the level of aggression that the wheel can deliver as well the dispersion aspects. This factor can also affect the speed at which sticky products such as paints and glues are removed from surfaces.

Any diamond segment that has sharp leading edges is capable of providing more aggression while tapered shapes result in better dispersion if they are set/oriented in the right direction.

Segment Bond

When deciding whether a particular diamond grinding wheel is ideal for use on a harder surface, you need to consider the segment bond as it has a direct impact on performance and rate of wear. The bond suspects the tiny pieces of polycrystalline diamond thereby preventing them from falling on the ground below the work station.

The bond is sacrificial, that is, it wears away as the wheel grinds on the surface to expose the diamond. This is important as the diamond has to be sharp to cut through or grind the surfaces. The force of friction acts upon the diamond as it moves over the floor.

It is also important to note that over time, the bond wears away around the diamond thereby exposing it even more. At a certain point, the exposed diamond splits and shatters thereby creating a sharper edge that continues to cut through the surface.

The degree of hardness of the surface will determine the length of time that the exposed diamond will remain sharp. For example, if the surface is hard, the sharp edges of the diamond will quickly become blunt and will need to constantly fracture to stay sharp.

On the other, if the surface is soft, the rate of wear increases because the dust and grit are abrasive to the bond. As a result, the bond is exposed and often splinter before it becomes blunt. Even though this aspect guarantees maximum grinding speed, it decreases its longevity/durability of the entire diamond wheel. A hard bond slows down the rate of wear to a reasonable level.

Diamond Grinding Wheel Grit

Compared to the other three fundamental aspects of a diamond grinding wheel that we have discussed, grit is the easiest to understand. Grit is usually a reference to the finishing qualities of the diamond segments in the wheel.

The lower the number, the coarser the grit (a large piece of the diamond) and vice versa is also true. That is, the higher the number the finer the grit (small piece of the diamond). Have you ever used sandpaper before, if yes, you already know that as the grit becomes smaller the finish becomes smoother? Right.

In most cases, 30 – 40 grit is the highest level of coarse required when doing a concrete grinding project. The degree of coarse exceeds 30, it will be harder to achieve and maintain even sharpness. On the other hand, if the grit is beyond 40, you will be able to create a smooth surface but productivity will be slowed down.

For polishing projects, it is recommendable to use 60-80 grit diamond grinding wheels. 100-150 grit wheel should be used before resign backed polishing pads. In general, a highly productive diamond grinding wheel will wear out faster than a slow productivity wheel. This is because, in the latter, the grip is always sharp.

As earlier discussed, a slow diamond grinding wheel will not release diamond as quickly as the fast wheel and therefore they will be blunt for extended periods.

Diamond Grinding Wheel Longevity and Speed?

Time is of paramount importance when doing any project. Using the wrong wheel, for example, one that has extremely aggressive properties can result in unnoticed/unexpected rapid wear. Strive to find the fastest and most ideal solution on your budget. The speed of production can surpass labor costs.

Types of Jobs

To help you understand which diamond grinding wheels you should purchase, we will review three different job times namely:

- Removal

- Leveling

- Pre-Polish

Removal of Coatings and Paint

Surface coatings such as paints are removed primarily by the shape of the diamond segment and not the other wheel properties. The surface area plays a critical role in the removal of the coatings. If the surface area is too much, the wheel will go run above the surface instead of cutting through it and dispersing it.

Bond and grit are less important in this kind of project but grit should be coarse enough to disperse the paint in instances that the wheel fails to slice the surface.

In the case of glues and other sticky materials, grit and bond characteristics do not come into play. But to remove excess concrete, all aspects – diamond segments, grit, and bond are relevant. To complete the project quickly, use wheels that have minimum segments and should have the right shape and a matching bond. Grit should be between 30-40 for the best results to be achieved.

Leveling

A more level surface will be achieved if the wheel has a larger diameter of the contact area. On the other hand, smaller contact areas will enable the grinding wheel to follow undulations but the larger wheel usually cut through the hurdles literally.

For the best value for money, it is recommended to use a diamond grinding wheel that has a larger segment as they tend to float over the surface instead of cutting it.

Pre-Polish

The first thing to do when polishing is by preparing the surface. All the surface material must be removed to make it smooth. A diamond grinding wheel with more surface area and small grit size will get the job done well.

Wheel with large diamond segments cannot cut through the surface as they tend to float over the surface instead of cutting through it. As a result, the segments will depend on the weight/pressure of the machine as well as the bond and grit characteristics of the diamond grinding wheel.

How to Import Diamond Cup Grinding Wheels from China?

Step 1: Identify the import rights

Various courier companies such as By sea / By railway/UPS/DHL/FedEx can help ship the products to your premises. But before you go ahead and shop, consider the import rights in your country. For example, if you are in the U.S, you need to provide your Social Security Number or company Internal Revenue Service Number.

Step 2: What do you want to ship

In this case, you are interested in buying diamond cup grinding wheels. Consider the specifications, pricing, and the quantity. Carry out extensive market research to know which type of grinding wheel cups are on high demand.

Step 3: Calculate the cost

Determine the total cost of buying the diamond cup grinding wheels and the importation costs. This includes the cargo transport cost as well as clearance charges at the port. This step will help you budget correctly for the entire shipping process.

Step 4: Find an Industrial Supplier

Most of the companies can ship the products for you or connect you to a credible supplier. If the latter is the case, make sure that you establish a direct communication line with the diamond grinding wheels supplier to avoid any inconveniences down the road.

Step 5: Track your Cargo

Shipping products such as diamond grinding wheels in bulk usually takes time but the wait is worth it considering the great quality and cost. Track the cargo to know the expected time of arrival. Note that it is the duty of the importer to make arrangements for examination and release of the diamond grinding wheels.

Step 6: Obtain the Shipment

Once the package arrives at the port, contact the customs broker to facilitate the customs clearance process. Once you get the goods, check the industrial quality, labels, instructions, packaging, and everything else to be sure everything is in order for your diamond grinding wheels.

Conclusion

The process of importing diamond cup grinding wheels does not have to be complicated and time-consuming. Follow the above tips to get your shipment in your country in no time. Make sure that you also consider all the factors that we have discussed to get the best quality industrial diamond grinding wheel.

Make you more trust that you have chosen the most reliable diamond grinding wheel supplier.