Cutting melamine can be tricky. You want a clean cut without chips or rough edges, but it takes a little know-how to get it just right.

To cut melamine without chipping, use a fine-tooth blade (80+ teeth) designed for laminates. Score the cut line on both sides, apply masking tape to support the surface, and feed the material slowly and steadily through the saw. Proper blade choice and technique ensure clean, smooth edges. Choose a high-quality fine-tooth blade designed for melamine or laminates, ideally with 80 or more teeth. Score the cut line lightly on both sides before making the final pass. A slow, steady feed rate through the table saw helps minimize chipping.

It’s all about using the right blade and method.

Cutting Melamine without Chipping?

When it comes to melamine, the challenge is avoiding those pesky chips. Trust me, I’ve been there—trying to cut through the board only to end up with rough edges1 and an unsatisfied feeling.

To cut melamine without chipping, use a fine-tooth circular saw blade, preferably 80-100 teeth, and consider scoring the surface before making the full cut. Keep the blade sharp, and use masking tape along the cutting line to support the melamine layer and reduce the risk of chipping.

Most chips occur when the teeth that are not actually removing material come in contact with the surface. By cutting one side at a time, you prevent most tear out. Turn the saw off, and back the piece back behind the blade. Or, if using a circular saw, set the saw in the same position.

Techniques for a Chip-Free Cut

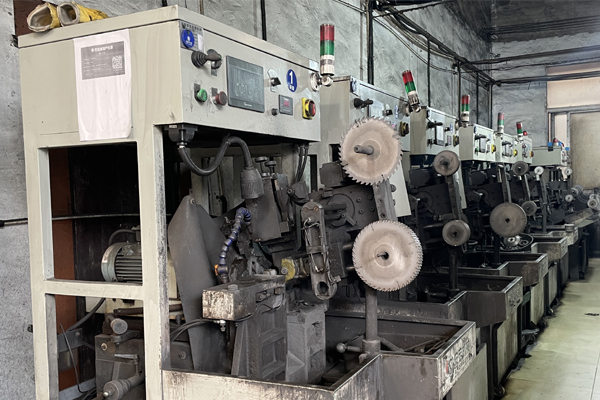

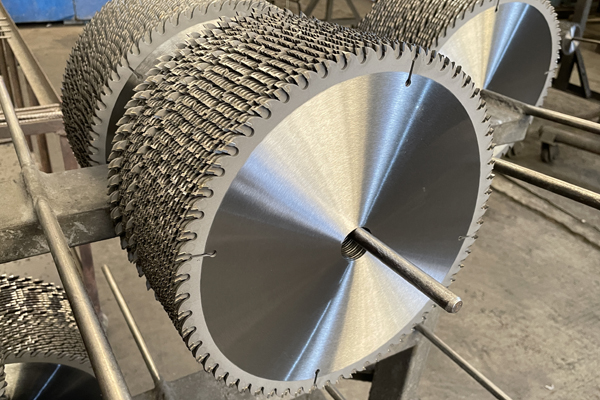

First off, always use the right blade. A sharp, carbide-tipped blade with lots of teeth is your best friend here. If you’re unsure, an 80-tooth or higher saw blade made for melamine or laminates will do wonders. Why? Well, the more teeth, the cleaner the cut—simple as that.

Also, consider the scoring technique. This means running the blade along the cut line just enough to cut through the top layer without going all the way through. Then, when you make your actual cut, the top surface has already been cleanly severed, reducing any chance of chipping.

Another trick is using masking tape along the cut line. Place tape on both sides to give the top layer some extra support. And hey, slow and steady wins this race. Feed your melamine through the saw at a moderate pace—too fast, and you risk more chips.

How to Cut Laminate Countertops?

Cutting laminate countertops is like trying to keep icing on a cake from cracking—it’s all about the finesse.

To cut laminate countertops, use a fine-tooth blade, and place masking tape along the cutting line to prevent splintering. Always cut with the laminate face down when using a circular saw. A jigsaw with a fine-tooth blade can also work for more intricate cuts, like corners and sink cutouts.

Finding the Sweet Spot for Cutting Laminate

Laminate can be tricky since it’s a bit more delicate compared to standard wood. You’ll want a sharp blade with plenty of teeth, again—80 or more is ideal. For those smooth, straight cuts, a circular saw2 works well. But remember, face the laminate side down to get the cleanest cut from underneath where the blade exits.

If you need to make more detailed cuts, like around a sink, a jigsaw with a fine-tooth blade is perfect. Just keep in mind that it’s super easy to chip laminate, so slow movements and good support are key. And a bonus tip? Always measure twice, cut once. Nothing’s worse than realizing your perfect cut doesn’t quite fit.

Is More Teeth on a Circular Saw Blade Better?

You might have heard people say, "More teeth make a better cut," but is that really true for every job?

Yes, a saw blade with more teeth generally provides a smoother cut, especially for materials like melamine or laminate. More teeth mean less material removed per tooth, which results in finer cuts and fewer chips. But for rough cutting or thicker wood, fewer teeth might be better for speed and efficiency.

Choosing the Right Blade for the Job

When you’re cutting something delicate like melamine, yes, more teeth mean a cleaner edge. A blade with 80 to 100 teeth will give you a finish that’s nice and smooth. Think of it like using a fine-tooth comb—the more teeth, the finer the control.

However, if you’re ripping through thick hardwood3, those extra teeth can actually slow you down and heat up the blade. For this kind of heavy-duty work, a 24- or 40-tooth blade works much better.

So, the "more teeth" rule really depends on what you’re trying to accomplish. More teeth for smooth finishes, fewer for power and speed.

What is the Best Saw for Cutting Laminate Flooring?

Ah, laminate flooring. It’s durable, it looks great, but cutting it to fit your space can be a bit challenging.

The best saw for cutting laminate flooring is a circular saw with a fine-tooth blade or a miter saw. Both of these saws allow for precise cuts, which is crucial when fitting the flooring perfectly into your space. If you need to trim pieces already in place, a jigsaw can also be handy.

Tools That Make Cutting Laminate Easy

Laminate flooring can be awkward to handle, especially with those longer boards. A miter saw is excellent if you’re making straight cuts4 across the planks—it keeps the line clean and the work simple. If you’re cutting lengthwise, a circular saw with a sharp, fine-tooth blade will do just fine. Place the board face down to avoid chipping on the finished side.

For those trickier, in-place cuts or detailed areas, a jigsaw can be helpful, though it requires a steady hand to avoid chipping. There’s also a specialized tool called a laminate cutter, which can work wonders without the noise or dust of a power saw. It’s slower, but it’s super easy to use if you’re not in a rush.

Fazit

Cutting melamine and laminate doesn’t have to be a headache. With the right blade, steady hands, and some thoughtful prep, you’ll get that clean, chip-free finish every time.

-

Rough edges indicate improper cutting techniques or tool setup, identify and address the causes of rough edges, enhancing the overall cutting quality. ↩

-

A circular saw is a widely used tool for straight cuts, for achieving professional cutting results. ↩

-

Fewer teeth are better for cutting dense, thick materials, and choosing the right blade for heavy-duty tasks. ↩

-

Achieving clean, precise straight cuts with a miter saw, which is essential for professional-looking results. ↩