Ever wondered how long your diamond blade will last? It’s a common question for anyone who relies on these powerful tools. Let’s dive into the details together.

Diamond blades are essential for cutting through tough materials like concrete, stone, and asphalt. Their longevity depends on various factors, including usage, maintenance, and the type of material being cut. On average, a diamond blade can last anywhere from a few hours to several weeks, making them a valuable investment for both professionals and DIY enthusiasts.

Understanding the lifespan of your diamond blade can help you get the most out of your investment.

What are Diamond Saw Blades?

What exactly makes a diamond saw blade different from other blades?

Diamond saw blades are equipped with industrial-grade diamonds embedded in their edges, allowing them to cut through extremely hard materials with ease. These blades are designed to offer precision, durability, and efficiency, making them a top choice for various cutting applications.

Diamond saw blades are not just your average cutting tools. They represent a fusion of advanced engineering1 and material science, bringing unparalleled performance to demanding cutting tasks.

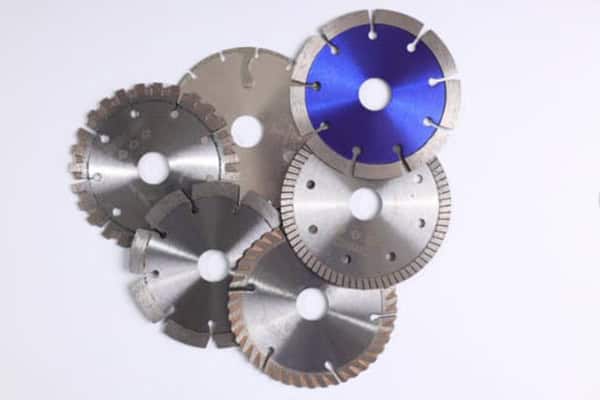

Types of Diamond Blades

- Segmented Blades: Ideal for dry cutting, these blades have spaces between segments for better cooling and debris removal.

- Continuous Rim Blades: Best for wet cutting, they offer smoother finishes without chipping.

- Turbo Blades: A hybrid between segmented and continuous rim, providing versatility for different materials.

Factors Affecting Longevity

- Material Being Cut: Harder materials cause more wear and tear on the blade.

- Cutting Technique: Proper technique reduces unnecessary stress on the blade.

- Maintenance: Regular cleaning and proper storage extend the blade’s life.

- Blade Quality: Higher quality blades with better diamond concentration last longer.

| Factor | Impact on Blade Longevity |

|---|---|

| Material Hardness | Harder materials wear blades faster |

| Schneidgeschwindigkeit | Higher speeds increase wear |

| Maintenance Practices | Good maintenance extends life |

| Blade Quality | Higher quality blades last longer |

By understanding these aspects, you can make informed decisions to maximize your diamond blade’s performance and lifespan.

Diamond Blade Composition

The heart of a diamond blade lies in its composition. The diamonds are bonded to the blade’s edge using a special matrix, which is typically sintered.

- Sintered Bonds: These provide flexibility, making them suitable for harder materials. They allow the diamonds to move slightly, reducing the risk of chipping and enhancing the blade’s durability.

Advancements in Diamond Blade Technology

Over the years, diamond blade technology has seen significant advancements. Innovations such as enhanced bonding techniques and improved diamond concentration have contributed to longer-lasting and more efficient blades.

- Enhanced Bonding Techniques: Modern blades use advanced methods to secure diamonds more effectively, ensuring they remain intact during prolonged use.

- Improved Diamond Concentration: Higher diamond concentrations lead to faster cutting speeds and extended blade life, especially when dealing with abrasive materials.

By staying updated with these technological advancements, you can choose blades that offer the best performance and durability for your specific needs.

Real-World Applications

Diamond blades are used in a variety of industries due to their exceptional cutting capabilities:

- Construction: Cutting concrete, asphalt, and masonry with precision.

- Stone Fabrication: Shaping and sizing natural stones like granite and marble.

- Roadwork: Slicing through tough road materials for repairs and maintenance.

- Tile Installation: Providing clean and accurate cuts for ceramic and porcelain tiles.

Each application may require different blade types and maintenance practices to ensure optimal performance and longevity.

Environmental Impact

Using diamond blades can also have environmental benefits. Their efficiency reduces the time and energy required for cutting tasks, leading to lower fuel consumption and reduced emissions on job sites. Additionally, their durability means fewer blades are disposed of, minimizing waste.

How Do You Check a Diamond Blade?

How can you tell if your diamond blade is still in good condition?

Regularly inspecting your diamond blade is crucial to ensure optimal performance and safety. Look for signs like uneven wear, missing segments, or excessive glazing. Using a magnifying glass can help spot micro-chips or cracks that aren’t visible to the naked eye.

Keeping an eye on your blade’s condition can prevent costly mistakes.

Regular inspections might seem tedious, but they’re essential for maintaining the blade’s effectiveness and ensuring safety during use.

Visual Inspection

Start with a thorough visual check:

- Uneven Wear: Look for areas where the blade has worn down more than others.

- Missing Segments: Ensure no segments are broken or missing, as this can affect cutting performance.

- Glazing: A glazed or shiny surface indicates excessive heat buildup, which can dull the blade.

Performance Testing

- Cut Quality: Notice if the blade is producing clean cuts or leaving rough edges.

- Cutting Speed: A slower cutting speed than usual can signal blade wear.

- Noise Levels: Increased noise during operation can indicate damage or wear.

Maintenance Checks

- Tension: Ensure the blade is properly tensioned; loose blades can be dangerous.

- Mounting: Check that the blade is securely mounted and free from vibrations.

- Cooling System: For wet blades, verify that the cooling system is functioning correctly to prevent overheating.

Tools for Inspection

Using the right tools can make the inspection process more effective:

- Magnifying Glass: Helps identify micro-chips and cracks.

- Blade Indicator: Measures the runout and balance of the blade.

- Lubricant: Regularly apply the appropriate lubricant to reduce friction and wear.

By regularly performing these checks, you can catch potential issues early and ensure your diamond blade remains in top condition, extending its useful life.

Personal Anecdote: The Cost of Neglect

I remember the first time I ignored a small crack I noticed during an inspection. It seemed minor, but during a crucial project, the blade failed, causing not only delays but also additional costs. From that day on, I never skipped inspections, no matter how busy I was. It was a hard lesson, but it underscored the importance of regular blade2 checks.

Common Inspection Mistakes

- Relying Solely on Visual Cues: Sometimes, damage isn’t visible to the naked eye. Using tools like magnifying glasses or blade indicators can reveal hidden issues.

- Skipping Maintenance Checks: Ensuring the blade is properly tensioned and mounted is just as important as checking for wear.

- Ignoring Performance Changes: If you notice changes in cut quality or speed, it’s a sign that the blade needs attention, even if it looks fine.

How Does a Diamond Blade Work?

Ever curious about the mechanics behind diamond blades?

Diamond blades work by using industrial diamonds bonded to the edge of the blade. As the blade spins, the diamonds grind away at the material, creating a precise cut. The continuous contact between the diamonds and the material ensures efficient and effective cutting, even on the toughest surfaces.

Let’s explore the fascinating process that makes these blades so effective.

Understanding how a diamond blade operates can give you insights into why it performs so well and how to maintain it properly.

The Cutting Process

At the heart of a diamond blade’s functionality is the abrasive action of diamonds:

- Grinding Action: The diamonds grind away the material as the blade rotates, rather than cutting through it like a traditional blade.

- Heat Dissipation: The design of the blade allows for efficient heat dissipation, preventing overheating and maintaining blade integrity.

Blade Composition

- Diamond Concentration: The number of diamonds per square inch (DPT) affects the blade’s cutting speed and durability.

- Bond Type: The type of bond (sintered) influences the blade’s flexibility and how it wears down over time.

- Sintered Bonds: More flexible, better for harder materials.

Cutting Techniques

- Wet vs. Dry Cutting: Wet cutting uses water to cool the blade and reduce dust, while dry cutting is quicker but can cause more wear on the blade.

- Speed and Pressure: Maintaining the right speed and applying consistent pressure ensures efficient cutting and prolongs blade life.

Efficiency Factors

- Blade Size and RPM: Matching the blade size with the appropriate RPM ensures optimal performance.

- Material Properties: Knowing the hardness and abrasiveness of the material helps in selecting the right blade type.

| Component | Funktion |

|---|---|

| Diamanten | Provide the abrasive action for cutting |

| Bond Material | Holds diamonds in place and affects flexibility |

| Blade Structure | Ensures stability and heat dissipation |

| Cooling System | Prevents overheating and reduces wear |

The Role of Industrial Diamonds

Industrial diamonds are the cornerstone of diamond blades. Unlike gemstones, these diamonds are not valued for their appearance but for their unparalleled hardness3 and abrasive qualities. They enable the blade to cut through materials that would quickly dull or destroy conventional blades.

Bonding Techniques

The method used to bond diamonds to the blade significantly impacts performance:

- Sintered Bonding: This involves heating the diamond and blade materials together until they fuse, creating a strong bond that allows for flexibility. This flexibility helps in maintaining the blade’s integrity during intense cutting operations.

Thermal Management

Effective thermal management is crucial for maintaining blade performance. Excessive heat can degrade both the diamonds and the bond, leading to reduced cutting efficiency and shorter blade life. Proper cooling systems, whether through water or air, help maintain optimal operating temperatures.

Real-World Application: Cutting Through Concrete

Cutting through concrete with a diamond blade is a common task in construction and renovation. The blade’s diamonds grind through the dense material, creating clean, precise cuts with minimal effort. Understanding the blade’s mechanics allows for better handling and longer-lasting performance, ensuring that projects are completed efficiently and effectively.

Maintenance and Operation Best Practices

To ensure your diamond blade operates at peak efficiency:

- Proper Installation: Ensure the blade is installed correctly to avoid imbalance and vibrations.

- Consistent Use: Avoid sudden starts and stops, which can stress the blade.

- Regular Monitoring: Keep an eye on blade performance and condition throughout use.

Safety Considerations

Using diamond blades safely is paramount:

- Protective Gear: Always wear appropriate protective equipment, including gloves, goggles, and ear protection.

- Secure Workpiece: Ensure the material being cut is firmly secured to prevent movement during cutting.

- Proper Handling: Handle blades with care to avoid accidents and extend blade life.

Innovations in Diamond Blade Design

The industry continues to innovate, introducing new designs that enhance performance:

- Laser-Guided Blades: Incorporate laser guides for more accurate cuts.

- Smart Blades: Equipped with sensors to monitor blade condition in real-time.

- Eco-Friendly Blades: Designed with sustainable materials and processes to reduce environmental impact.

How to Extend the Life of a Diamond Saw Blade?

Want to make your diamond blade last longer?

Absolutely! Proper maintenance and mindful usage can significantly extend the life of your diamond blade. Regular cleaning, using the right cutting techniques, and ensuring proper storage are key steps. Additionally, selecting the appropriate blade for your specific tasks can prevent unnecessary wear and tear.

Let’s talk about some practical tips to keep your blades in top shape.

Extending the life of your diamond blade is all about taking proactive steps and being mindful of how you use and care for it.

Maintenance Tips

- Regular Cleaning: Remove debris and buildup after each use to prevent clogging and overheating.

- Proper Storage: Store blades in a dry, cool place to avoid rust and damage.

- Inspect Before Use: Always check for cracks or missing segments before starting a new project.

Optimal Usage

- Correct Speed: Operate the blade at the recommended RPM to avoid excessive wear.

- Appropriate Pressure: Apply steady, moderate pressure. Too much force can damage the blade, while too little can reduce cutting efficiency.

- Use Suitable Coolant: For wet blades, ensure an adequate flow of water to keep the blade cool and reduce dust.

Choosing the Right Blade

- Match Blade to Material: Using a blade designed for your specific material type minimizes unnecessary wear.

- Quality Over Cost: Investing in higher-quality blades may cost more initially but save money in the long run by lasting longer.

- Consider Blade Features: Features like segment design should align with your cutting needs to maximize efficiency and lifespan.

Proactive Practices

- Rotate Blades: If you use multiple blades, rotating them can distribute wear evenly.

- Sharpen When Needed: Some blades can be sharpened to restore their cutting edge, extending their usability.

- Train Properly: Ensure that operators are trained in the correct handling and usage techniques to prevent accidental damage.

| Tipp | Benefit |

|---|---|

| Regular Cleaning | Prevents clogging and overheating |

| Proper Storage | Avoids rust and physical damage |

| Correct Speed and Pressure | Enhances cutting efficiency and blade life |

| Choosing Right Blade | Minimizes unnecessary wear |

Personal Insight: The Importance of Training

I’ve seen firsthand how proper training can make a significant difference in blade longevity. When new team members are thoroughly trained on the correct usage and maintenance of diamond blades, not only does the blade last longer, but the quality of work improves as well. It’s a win-win situation that benefits both the tool and the project outcomes.

Advanced Maintenance Techniques

For those looking to take their blade maintenance to the next level, consider the following advanced techniques:

- Blade Dressing: This involves sharpening the blade to restore its cutting edge. Regular dressing can significantly extend blade life.

- Coolant Management: Using the right type and amount of coolant can reduce heat buildup and prevent premature wear.

- Automated Cleaning Systems: In industrial settings, automated systems can keep blades clean and free from debris, ensuring consistent performance.

Environmental Considerations

Proper blade maintenance also has environmental benefits. By extending the life of your diamond blades, you reduce waste and minimize the environmental impact associated with manufacturing and disposing of blades. Additionally, using water efficiently in wet cutting can help conserve resources and reduce dust pollution.

Real-World Example: Construction Site Efficiency

On a busy construction site, time is money. By implementing regular maintenance schedules and training workers on optimal usage techniques, a team can ensure their diamond blades perform efficiently throughout the day. This not only keeps projects on schedule but also reduces the frequency of blade replacements, leading to significant cost savings over time.

Common Mistakes to Avoid

- Ignoring Manufacturer Guidelines: Always follow the manufacturer’s instructions for usage and maintenance to avoid voiding warranties and ensuring optimal performance.

- Overloading the Blade: Applying too much pressure can cause excessive wear or even blade failure.

- Using the Wrong Blade for the Material: Matching the blade to the material is crucial for maintaining blade integrity and achieving the best cutting results.

Long-Term Strategies for Blade Longevity

- Inventory Management: Keep track of blade usage and rotate your inventory to ensure that no single blade is overused.

- Investment in Quality Tools: Higher-quality blades may have a higher upfront cost but offer better performance and longer life, providing better value in the long run.

- Continuous Improvement: Regularly review and update your maintenance practices based on the latest industry standards and technological advancements.

By implementing these strategies, you can ensure your diamond blades remain effective and last longer, providing you with reliable performance for all your cutting needs.

The Economics of Blade Longevity

Investing in high-quality diamond blades may seem expensive initially, but the long-term savings are substantial. Fewer blade replacements mean reduced operational costs and less downtime. Additionally, higher-performing blades can increase productivity, allowing more work to be completed in less time.

Case Study: Maximizing Blade Efficiency

Consider a mid-sized construction company that switched to high-quality sintered diamond blades. By implementing a strict maintenance schedule and training their workforce, they extended the life of their blades by 30%. This not only reduced their costs but also improved their project timelines, leading to increased client satisfaction and repeat business.

Technology Integration for Maintenance

Modern technology offers tools that can aid in blade maintenance:

- Digital Monitoring Systems: These systems track blade usage and performance in real-time, alerting you to potential issues before they become serious problems.

- Data Analytics: Analyzing usage data can help identify patterns and optimize maintenance schedules, ensuring blades are serviced at the right times.

- Automated Alerts: Set up automated alerts for maintenance tasks, ensuring that no blade is neglected.

Sustainability and Blade Usage

Sustainability is becoming increasingly important in all industries. By choosing durable, long-lasting diamond blades and maintaining them properly, you contribute to a more sustainable operation. Reducing waste and conserving resources aligns with global sustainability goals and can enhance your company’s reputation.

Employee Training Programs

Effective training programs are essential for maximizing blade longevity:

- Comprehensive Training: Provide thorough training on blade installation, operation, and maintenance.

- Regular Refresher Courses: Periodically update training to incorporate new techniques and technologies.

- Hands-On Demonstrations: Practical demonstrations can help workers understand the importance of proper blade handling and maintenance.

The Future of Diamond Blade Technology

Looking ahead, diamond blade technology4 is poised to continue evolving. Innovations such as self-sharpening blades and blades with adaptive bonding materials promise even greater efficiency and longevity. Staying informed about these advancements can help you stay ahead in your industry and maintain optimal blade performance.

Practical Tips for DIY Enthusiasts

Even if you’re not a professional, extending the life of your diamond blades is achievable with some simple practices:

- Clean After Every Use: Wipe down your blade to remove any residue.

- Store Properly: Keep your blades in a protective case or storage area to prevent damage.

- Use Correctly: Follow the manufacturer’s guidelines for speed and pressure to avoid unnecessary wear.

Troubleshooting Common Issues

Encountering problems with your diamond blade? Here are some common issues and how to address them:

- Blade Dulling: If your blade isn’t cutting as effectively, it may need sharpening or replacement.

- Vibration: Excessive vibration can indicate imbalance or damage. Inspect the blade and ensure it’s properly mounted.

- Overheating: Ensure adequate cooling during cutting operations to prevent overheating and prolong blade life.

Building a Maintenance Routine

Establishing a consistent maintenance routine is key to maximizing blade longevity:

- Pre-Use Inspection: Check the blade for any visible damage before each use.

- During Use Monitoring: Keep an eye on performance and listen for unusual noises.

- Post-Use Cleaning: Remove debris and inspect the blade for any signs of wear.

- Scheduled Maintenance: Perform deeper maintenance tasks, such as sharpening and detailed inspections, on a regular schedule.

Leveraging Manufacturer Support

Don’t overlook the support offered by blade manufacturers:

- Technical Support: Reach out for assistance with blade selection, maintenance tips, and troubleshooting.

- Warranty Services: Take advantage of warranties to replace defective blades without additional cost.

- Educational Resources: Access training materials, guides, and best practices provided by the manufacturer.

Integrating Blade Maintenance with Overall Equipment Care

Blade maintenance should be part of your broader equipment care strategy:

- Tool Maintenance: Regularly service your cutting tools to ensure they operate smoothly with your diamond blades.

- Equipment Calibration: Keep your equipment calibrated to maintain optimal cutting performance.

- Spare Blade Inventory: Maintain an inventory of spare blades to minimize downtime when replacements are needed.

Feedback and Continuous Improvement

Gathering feedback from blade users can provide valuable insights:

- User Feedback: Encourage operators to share their experiences and suggestions for blade usage and maintenance.

- Performance Data: Collect data on blade performance to identify trends and areas for improvement.

- Continuous Improvement: Use the feedback and data to refine your maintenance practices and blade selection criteria.

Fazit

Taking good care of your diamond blades ensures they perform well and last longer. Implement these tips to get the most out of your tools.

-

Allow readers to explore the specific engineering principles that contribute to the effectiveness of diamond saw blades, offering a deeper understanding of the technology behind their high performance. ↩

-

Explaining how blade failure can cause delays and additional costs. ↩

-

An in-depth explanation of why hardness is such an important factor in the performance of industrial diamonds, which directly impacts the efficiency and lifespan of diamond blades. ↩

-

The latest trends in diamond blade technology help users gain a deeper understanding of the technological innovations shaping the industry, offering them a competitive edge. ↩