Cutting Discs Manufacturers

- Why Tenyu Tools is the Best Cutting Disc Manufacturer in the Market

- You won’t have problems with tooth-loss – all our discs are durably welded

- Tenyu Tools can deliver industry-specific cutting discs based on your need

- You can trust us and our R&D team in delivering high-quality products

- We’ll be able to get you all the cutting discs you need, wherever you may be

- After more than a decade of manufacturing cutting discs, Tenyu Tools has mastered the art of specifying client requests.

Being The Number One Cutting Disc Manufacturer in China, We’ll Never Fail You!

Whatever size, make, shape, and material you want – we can get it for you! A lot of our clients trust us when it comes to manufacturing specially and specifically-designed discs; they were never disappointed.

Tenyu Tools can manufacture electroplated, sintered, and brazed discs – you choose, we make!

Advantages of Choosing Our Cutting Discs

If there are a lot of other cutting disc manufacturers, why choose us here at Tenyu Tools?

Worn-out cutting blade, which you won’t ever experience with us!

A lot of our clients understand the following and continue to patronize our products and services:

- Tenyu Tools’ cutting discs are applicable for both wet and dry applications

- The bodies of all the cutting discs we manufacture are treated accordingly

- Tenyu Tools’ cutting discs have extended lifespans and life expectancies

- All our cutting discs are resistant to impact and weather

- And many more!

These are just some of the perks you can get if you choose us as your cutting disc manufacturer.

Work with us and know more about all the different cutting discs we offer!

Applications of Tenyu Tools’ Cutting Discs

You’ll be able to apply our cutting discs to cut a wide variety of materials, such as:

- Sheet metals

- Cast iron

- Tubes, pipes, and fitting

- Aluminum steel

- Stainless steel

Whether you’re a business in need of a cutting disc due to the nature of your business, or if you’re a retailer of tools and accessories, Tenyu Tools will be your best choice!

You can work with and we’re open to all business opportunities available!

Why Choose Tenyu Tools as Your Cutting Disc Manufacturer?

Choosing Tenyu Tools as your cutting disc manufacturer will be your best option.

We use state-of-the-art machines we ourselves manufactured

- We’re trusted by over 990 clients/businesses worldwide

- We can produce large volumes of tools and accessories in a single day

- All our products are made and manufactured using machines we built ourselves

- You can view all our products via our online showrooms and workshops

- We continue to innovate and strive to stay atop the industry’s ladder

Don’t hesitate to give us a nudge here at Tenyu Tools. We can give you a free quotation of all the cutting discs you need!

Contact us and get the cutting discs you need at the most reasonable rates and prices!

Inquiry now! We can reply in 24hours!

- Manufacturing Machine for Cutting Discs

- Applications of Cutting Blades Manufacturer?

Cutting Disc Manufacturer – The Ultimate FAQ Guide

A lot of companies stay uninformed on how they can find the best cutting disc manufacturer to work with.

With a lot of factors in play – adding the fact that there already are a lot of newcomers – it’s really a challenging task.

In this guide, we’ll help you understand cutting discs more. From what they are, how you can use them – to choosing the best and the most appropriate cutting disc manufacturer in the market.

What are Cutting Discs?

It’s a type of material you use for cutting steel and metal.

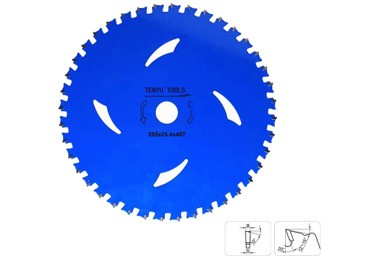

A cutting disc we’re offering here at Tenyu Tools

Otherwise known as cut off wheels, you’d usually find them made and manufactured from solid abrasive material.

Can You Use a Grinder as a Cutting Disc?

Grinders and cutting wheels or discs are pretty much the same thing.

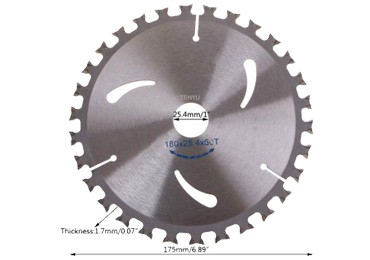

Sample of a grinding wheel we’re offering here at Tenyu Tools, which you can use to cut

The key difference is with the thickness; cutting discs are made to be thinner than grinding discs.

This allows a neater and a cleaner cut, compared to that of a grinding disc – which is specifically purposed to grind material.

However, you can use a grinding disc to cut or subtract materials, too!

What is a Cutting Disc Made Of?

More often than not, a cutting disc is a tool made from abrasive material, organic resins, as well as fiberglass.

The outside is comprised of an abrasive compound.

What are the Different Types of Cutting Discs?

You’re looking at cutting discs but you fail to recognize each of the types.

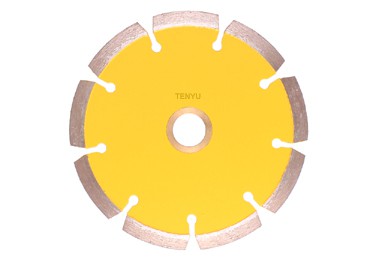

An example of two (2) different cutting discs or wheels we manufacture

Some of the most common types of tools cutting disc manufacturers produce, include:

Cut Off Discs

It’s the tool you’d use for cutting or slicing through various materials like metal or steel.

Sanding Discs

Alternatively known as a disc sander, it’s a type of sandpaper in the shape of a disc.

You use it to finely sand and finish a certain material. The quality of the finishing will depend on the grit you’ll use.

Abrasive Discs

They’re the general type of disc or wheel you’d want to use.

You can use them for grinding, cleaning, smoothing/sanding/polishing – or even finishing.

These are three (3) of the most common types of discs available in the market. There are a lot more but these are the discs that are known to be the most popular.

Different Cutting Disc Sizes

The sizes that cutting disc manufacturers make actually depend on what their best-sellers are.

In addition to that, there are suppliers that manufacture and supply industry and client-specific cutting discs.

If we’re talking about the most common size of cutting discs, it’s 9” and 4.5”.

How Do I Know the Cutting Disc to Use?

Cutting discs or wheels with a larger diameter tend to be used in a wide range of heavy-duty applications.

The manufacturing process of cutting discs that are separated by different categories

This would involve usage of the disc for maximum hours, for thick materials and workpieces, etc.

Wheels and/or discs that are smaller, however, are useful for finer, cleaner, and smoother work. Each would have a different result and therefore, you need to be wary of the disc you’ll purchase.

Can I Use a Metal Cutting Disc on Concrete?

Yes, you will be able to work on concrete, as well as other types of masonry using cutting discs.

A cutting disc cutting through a thick slab of concrete

In fact, you will be able to cut through even harder, thicker, stronger materials.

What’s Included in a Cutting Disc Label?

Several cutting disc manufacturers might label their discs differently.

Cutting disc label with all the information about the cutting wheel

The labels are different, but, we’ll be able to identify them by dividing or categorizing them.

First things first; at the top of the disc, the label is the name of the product. It also has the code, the application, the speed applicable, as well as the dimensions or the measurements of the disc/wheel.

What Type of Cut Off Wheel is Used for Stainless Steel?

The best cutting disc you can use to cut or slice through stainless steel is zirconia grain.

Cutting wheel cutting through a strip of stainless steel

Because of its properties, as well as the fact that it has high tensile strength, it’d be the best. The most common types of zirconia-grain cutting discs come in 1/32 and 1/16-thick cut off wheels.

The grit could sit between 46 grit to a grit of 60, depending on how you like it.

What are the Usual Specifications of Cutting Discs?

Before purchasing a specific cutting disc for your need, it’s important to take note of the following characteristics:

Grain Size

This describes the size of each grain present on the abrasive or the outer layer of the disc.

Typically, discs with a larger grain will be able to cut faster and easier; but the smoothness might not be as good as how you want it to be.

Smaller and finer grains are perfect for quality and precision-work.

Hardness

Generally speaking, the hardness of a cutting wheel describes the difficulty level or degree to which the abrasives fall while being used.

It basically is the level of durability in which the grains are able to resist wear.

Wheel Grade

The “wheel grade” refers to the hardness or the tenacity of how the bond is in the context of it holding the grains in place.

Don’t be confused – it’s not the hardness of the grain of the abrasive itself. It’s the typical hardness of what’s holding the grains.

Bond Type

The bond type is the kind of material holding the abrasive in place. There are various types of bonds – welding, among others.

Grain Spacing

Lastly, the grain spacing is the distance of one grain to another.

The compactness and the closeness of each abrasive are relatively important as it dictates the proprietary strength of a disc.

These are just some of the specifications you need to note when it comes to cutting discs. Some cutting wheel manufacturers are open to discussing this, while there are some that just display it on the label.

Can I Use Cutting Discs for Wood?

Cutting discs are primarily used for cutting through hard and thick materials.

A cutting disc is best used for harder materials than regular wood

As we’ve discussed, you’ll be able to use a cutting disc to cut through marble, stone, concrete, as well as steel, and metal.

In answering the question, yes, you can use a cutting disc to cut wood. However, it wouldn’t be the best and the most ideal since wood isn’t actually that hard.

Why? Because wood is combustible; the abrasives on a cutting disc can contribute to make a wood fire or ignite up – resulting in a problem.

The Most Common Problems With Cutting Discs

If you thought cutting discs are all precious, think again.

An example of a problem or a defect that a cutting disc has

Akin to other types of cutting tools and materials, cutting discs have some problems and defects, too.

The most common defects cutting disc manufacturers need to take note of include:

The chattering of the Wheel

You’ll know wheel chatter when the rotation or the rolling of the wheel is already inconsistent. In addition to that, it also can result in the wheel losing and regaining grips.

The most common causes of it include:

- The vibration of the machine

- Imbalanced wheel

- Spindle vibration

Burning of the Workpiece

There are instances where the workpiece will be so fired up to the point where it can burn.

Part of the most common reasons for workpiece burning while cutting include:

- Wheel dressing is too fine or thin

- Fast feeding of the stock

- Coolant is not properly placed

Inappropriate Surface Finish

Has there been an instance where the finish of a cutting is not what you have been expecting?

It’s actually one of the most common problems you can experience in using cutting discs. The most common reasons for it include:

- Incorrect dressing of the wheel

- The wheel’s grade is too hard

- The dressing tool of the wheel is already worn out

Loading and Glazing of Wheel

Glazed wheels happen when the grains of the abrasive disc is already dull; loading, on the other hand, is when the external material becomes trapped in the spaces of the abrasive grit.

Some of the reasons why glazing and loading happen include:

- The grit of the wheel is too small or fine

- The abrasives are too hard or durable

You can put an end to this particular problem by:

- Using a grit that is softer and coarser

- Utilizing a sharper abrasive

- Increasing the traverse or the speed of the wheel dressing

There could be other problems and defects, but these are the most common problems you can experience when you use cutting discs.

Do Cutting Discs Have Expiry Dates?

Yes, not a lot of people actually know this, but cutting discs actually expire.

The location of where the expiry of a cutting disc usually is

As a matter of fact, you’ll see it printed on the center of the label – and it usually has the following format:

MM/YYY

The expiration of a cutting disc is existent because the bonds of these abrasives aren’t actually capable of holding them forever.

When the bond is deteriorating, you’ll see that it’s slowly starting to wear out.

Usually, the location would be at the center of the disc. This is for clients to easily see it. However, some manufacturers have it located someplace else.

Top Cutting Disc Manufacturers in the Industry

There is a myriad of cutting disc manufacturers you can trust. However, you might not be pleased with the rates and prices.

Since they’re popular brands, they’ve already established themselves, allowing them to price their products highly and differently.

The most common manufacturers of cutting discs are:

- Tyrolit

- LAM PLAN

- RHODIUS

- Weiler

- Walter Surface Technologies

- Osborn

These popular and leading brands are as is because of the effects they’ve offered their clients. So, don’t expect that you’ll save a lot of money if you patronize these brands.

Which Cutting Disc Supplier Should I Trust?

Out of all the cutting disc suppliers in the market, which one should you trust and work with?

Here in China, no other cutting disc manufacturer has trusted but us here at Tenyu Tools. We’ve been the most relied on and trusted supplier for over 15 years!

You can ask us to help you with whatever requirement you have with your cutting wheels!

With us here at Tenyu Tools Co., Ltd., you can get tremendous-quality cutting discs for a considerate price!

Why Tenyu Tools Co., Ltd. is Your Best Option?

- We’ve helped and assisted more than 990 clients

- We can help you create the cutting discs you need with the specifications you need

- You can bank and count on us wherever you are

- All our cutting discs are checked and assessed duly

You don’t have to worry about legitimacy – we here at Tenyu Tools Co., Ltd. are certified and licensed.

We have certifications that are applicable and accepted in Africa, Asia, Australia, Europe, and the Americas!

Do We Have a Minimum Order Quantity (MoQ)?

Tenyu Tools Co., Ltd., being the best cutting disc manufacturer, only requires a minimum order of 100 pieces.

Unlike other companies that have a minimum of 500 to 1,000 – you only need to order 100 pieces to order from us!

That’s a relatively low requirement, considering the quality of our products.

What is the Difference Between a Cutting Wheel and a Cutting Disc?

A lot of people often find difficulty in determining a cutting disc from a cutting wheel. But, are they the same, or are they different?

To cut to the point straight, cutting wheels and cutting discs are technically the same. They’re both used for cutting, and they only differ when it comes to the shape or the overall form of the disc.

The primary difference between a cutting wheel and a cutting disc is the shape. Cutting wheels have the distinctive factor of having a depth on the middle of the disc while cutting wheels don’t. They’re usually just a flat-out surface with a hole in the middle.

But, they’re both offered to have the same user while the other tends to lean more on the side that it’s purposely made for.

Best Cutting Disc For Metal

While the market is filled with a ton of different options, there are various cutting discs for metal that are considered the best and most effective.

According to customer demand the top cutting discs for metal cutting discs, the best one would be the DEWALT general-purpose metal cutting disc that’s sized at 4-1/2 inch.

It’s a type of multi-purpose blade that’s about 0.45” thin in diameter that is specially designed for fast cutting. One of the primary advantages of choosing the DEWALT general purpose metal cutting wheel is that it’s durable and long-lasting.

Moreover, it’s not only suited for cutting, you can also use it for grinding, polishing, and even for sharpening as well!

If you’re interested to get the DEWALT general purpose cutting disc, you might have problems with its price, because, to be totally fair, it’s not that cheap.

Get the same quality of cutting disc from us here at Tenyu Tools without the risk of paying for high rates and prices! We can produce OEM cutting discs that meet – even exceed some of the market’s top picks for cutting discs!

We’ll get to that in the latter part of the article. For now, do you know what you really need for the project you’re doing?

Cutting Disc vs. Grinding Disc: Which One Do You Need?

Just like you, a lot of people have the constant battle in deciding whether they need a grinding disc or a cutting disc for their application.

But, what really are the distinctive factors involved? What makes a cutting disc different from a grinding disc?

In this table below, we’ll be outlining some of the most notable differences that they have with one another.

| Cutting Discs | Grinding Discs |

| Cutting discs are primarily used for the purpose of cutting materials into two (2) or more pieces. | Grinding discs are for the purpose of grinding, or, other times, polishing of the edges of materials. |

| Typically thin, about 2.5 mm thick on average, but can be as thin as 1mm. | Thicker than cutting discs and are usually above 3mm in thickness. |

| Usually made from carbon or high-speed steel (HSS) for the body of the disc. | Fiberglass is often used as the primary body of the disc. |

| Topped and polished with abrasives (usually synthetic diamonds) on the edges of the disc for better and more accurate cutting. | Abrasives are poured into the mold to create the outer layer of the grinding disc. |

These are the common differences and distinctions of cutting discs and grinding discs.

Cutting Disc For Grinder: Is it Possible?

If you initially thought that cutting discs’ sole purpose is to cut, slice, and shear, you’re wrong!

There are several cutting discs that have been engineered to be able to grind, polish, deburr, and even finish certain materials, bringing out the best in them.

So, to answer the question, yes, you can use a cutting disc and mount it onto a grinder. A lot of cutting disc manufacturers do not actually mention this, but it’s actually what the case is.

Angle Grinder Wheels

These are the wheels or the discs that you mount onto angle grinders, which is purposely for the process of cutting, deburring, finishing, grinding, and even polishing.

Ideally, you can mount cutting discs to angle grinders, too because of the fact that that the hole on the middle of it is round/circular. Therefore, it’ll be easy and convenient to mount even cutting wheels and discs onto it.

There are several types and kinds of angle grinder wheels in the market. However, the most common would be:

- Angle Grinder Wheels For Metal

- Angle Grinder Wheels For Wood

- Angle Grinder Wheels For Concrete

These different types of angle grinder wheels will be different from one another. For instance, an angle grinder wheel for metal would have a different composition of materials. The parts and components of it should be capable of cutting metal, steel, as well as other materials of the like.

On the other hand, angle grinder wheels for concrete would usually be embedded with synthetic diamonds on the edges of it. This is to ensure that the blade or the disc wouldn’t break easily.

4-Angle Grinder Wheels

4-angle grinder wheels are considered as the most common or the standard size of grinder wheels or cutting discs.

Because of the fact that most applications of these cutting discs would be for materials that are thinner than 4 inches, a 4” angle grinder would already be enough.

You’ll find a lot of 4-inch angle grinder cutting discs in the market today. You’ll easily be able to find them on websites like Amazon, eBay, Bosch Tools, Home Depot, and many more!

However, if you’re looking for wholesale cutting discs, going with websites and resources such as Alibaba, Made in China, AliExpress, Trade India, and India Mart would be your best choices.

Not only will you have higher profitability when you choose a Chinese cutting disc manufacturer, you’ll also be exposed to various markets and suppliers within the supply chain of what you are dealing with!

Cutting Disc Manufacturers in China

The cutting disc manufacturers in China are known to be the most dominant in the industry, due to the fact that companies, corporations, and enterprises around the world have trusted them dearly.

In fact, the majority of European and American cutting disc suppliers go and work with Chinese cutting disc factories to produce their products wholesale! From them, they’ll proceed to assemble it, and then rename it so that they can call it their product.

But out of all the various cutting disc manufacturers in China, which one should you work with?

For many years, businesses in and out of the country have relied on us here at Tenyu Tools Co., Ltd. for the cutting discs they need.

We’ve streamlined our processes to be able to offer only the best and highest quality of cutting discs to businesses and corporations globally.

We were able to inculcate and utilize various materials and components to further the effectiveness and efficiency of our products.

From those alone, you’d already have an idea why we are considered as the top and most trustworthy cutting disc manufacturer in all of China!

Why Choose Tenyu Tools as Your Cutting Disc Supplier?

While there are tons of cutting disc suppliers in the country, Tenyu Tools Co., Ltd. remains as the best and most trusted cutting disc manufacturer because of a few factors.

- We are comprised of a team that are considered as experts and masters of the industry

- We’re equipped with the latest, the best, and most advanced technology

- All of our sources here at Tenyu Tools are all in reliable positions of the supply chain

- Custom cutting discs are all available upon request

Tenyu Tools Co., Ltd. wouldn’t be labeled as the best and most skilled cutting disc supplier for almost two (2) decades if we only produced usual and regular-quality cutting discs.

With our help and the mixture of high-tech equipment and good-quality raw materials, we can assure you that the products you’ll be getting from us would befit whatever your business needs and requirements are!

What Other Products Can Tenyu Tools Offer?

Apart from our cutting discs, you can also entrust to us the production of other power accessories and components of power tools such as SDS chisel bits, hole saws, diamond cutting wheels, regular circular wood saws blades, and many more!

Reach out to us and get the exact types of cutting discs you need! Get a free quote within 24 hours by leaving a message on our website, and never overpay for the orders of your cutting discs ever again!

Can I Order Custom Made Cutting Discs From Tenyu Tools?

Yes, Tenyu Tools is a manufacturer that can help and assist you in manufacturing and producing custom cutting discs.

Whether you need a cutting disc with a specific dimension, a specific type of bond, or a type of abrasive, we will never fail you!

Whether you’re a business needing a cutting disc or if you’re a retailer or a merchandiser – we can help you!

Contact us and we’ll never let you down! Get the highest quality of cutting discs you need for whatever project you have!