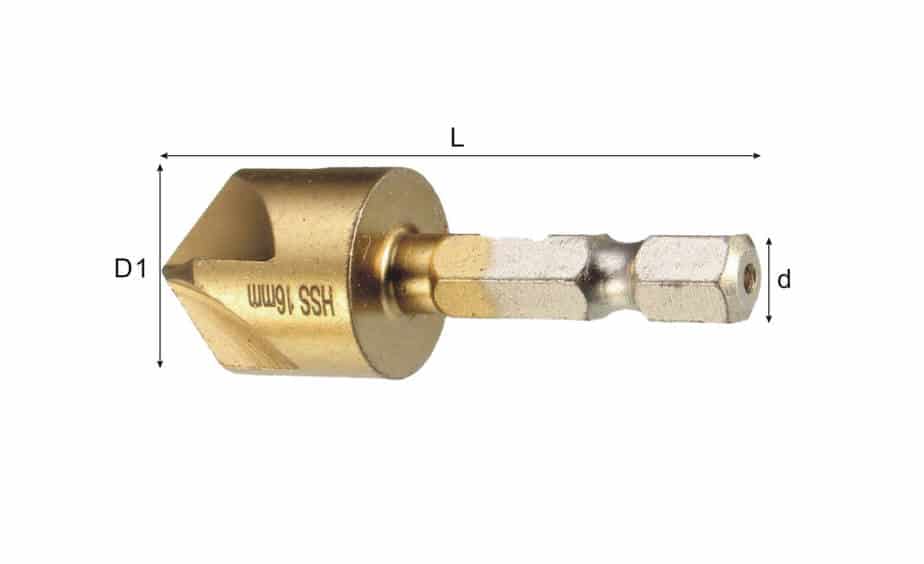

Countersink Drill Bit

- Tenyu Countersink Drill Bit

- Countersink Drill Bit materials: High Speed Steel (HSS).

- Countersink drill bit is a tool attaches to a drill press.

- Buy china best countersink drill bit in TENYU TOOLS.

Tenyu Countersink Drill Bit

Read This Countersink Drill Bits FAQ—

You Can Get How to Select Countersink Drill Bits for Flush-Set & Plugged Screws?

Countersink Drill Bit can be found in a selection of dimensions and also styles depending upon the task, the screws you’re making use of, and also individual choices. For energy store furnishings or various other spur-of-the-moment jobs– particularly momentary things– we usually uncommitted much regarding the screws. They can be noticeable or otherwise, pleased with the surface area or otherwise; occasionally, it simply does not matter.

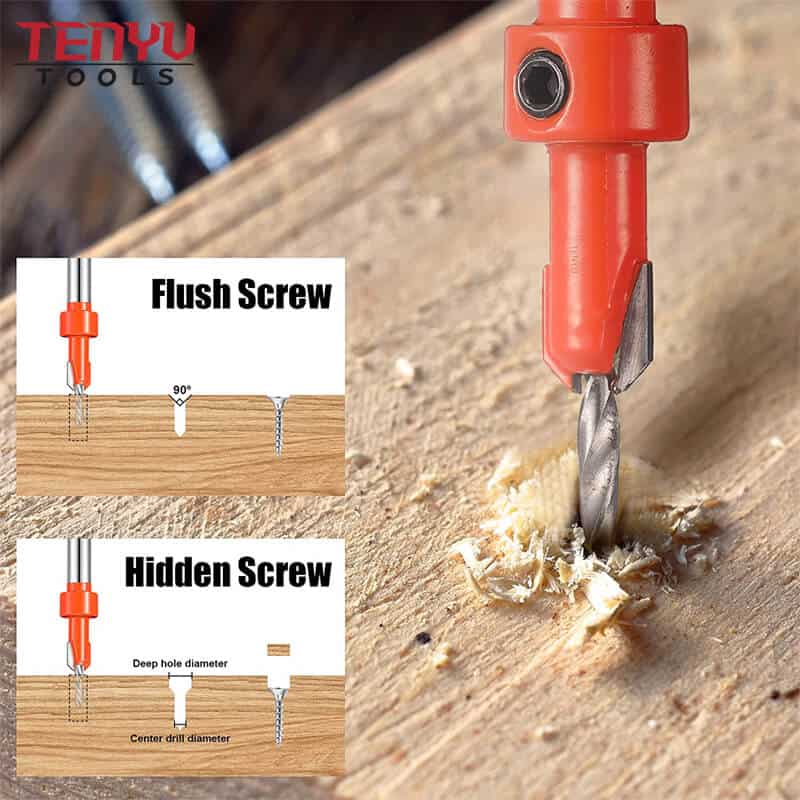

But also for a lot of our job, if a screw is mosting likely to show up we desire it to look great, seated flush, and also smooth with the bordering surface area whenever feasible. Certain, you can by force drive a flathead screw flush, however, that often splits the timber surface area fibers as well as looks dreadful. Inwood, you could not also have the ability to establish the screw flush. This is where Countersink Drill Biting (or its close loved one, counterboring) has been available. When you round off a pilot opening with a Countersink Drill Bit, the screw head seats completely: all its surface areas get in touch with the timber with the very same quantity of pressure, producing a tidy appearance as well as a solid accessory.

If you drill your Countersink Drill Bit deep sufficient to permit for them to be glued in over the screw, you can conceal your flat-head screws with timber connects. When we desire those screws to go away totally, an appropriately sized deep-drilled Countersink Drill Bit can approve a wood plug that can after that be reduced as well as a fined sand flush for an accented look as well as a smooth surface area. Managing these jobs, and also much more, is the work of a specialized Countersink Drill Bit. Yet there is a great deal of them available: one item or a mix of drill bit, as well as Countersink Drill Bit, single-fluted or with several grooves (or none whatsoever) as well as a vast array of chamfer angles, create a complicated choice. Similar to nearly all woodworking jobs, Countersink Drill Bits function best when appropriately matched to the task available.

Types of Countersink Drill Bits

A relatively current sort of one-piece Countersink Drill Bit called a cross-hole Countersink Drill Bit has no grooves. As opposed to sharp reducing sides, the bit has actually an opening tired via the cone at an angle. As the bit rotates, the tracking side of the hole makes it. Utilized similarly as fluted bits (pilot opening initially, Countersink Drill Bit 2nd), cross-hole Countersink Drill Bit Drill Bits reduced extremely efficiently and also eliminate product swiftly, and also they stand out at expelling chips as they drill. These drill bits usually set you back a bit greater than their fluted relatives.

Fluted bits have several reducing sides, cross-hole Countersink Drill Bits have a tilted opening in the suggestion which works as the reducing side. One-piece Countersink Drill Bits can be found in 2 major tastes, one of the most generally identified being a fluted Countersink Drill Bit, which has a brief shank with a lengthened cylindrical tube covered with a cone-shaped pointer. (The form constantly advises me of the old Apollo command module.) One of the most common fluted Countersink Drill Bit made use of to have 4 reducing sides on the cone, although one-piece fluted Countersink Drill Bits today a lot more generally have a strange variety of reducing sides– normally one or 5.

Fluted Countersink Drill Bit has been available in numerous dimensions, able to reduce cone-shaped openings planned to fit screws of differing head measurements. A pilot opening is first pierced for the screw, complied with by Countersink Drill Biting the hole to permit a flat-head screw to seat flush with the job surface area. It’s constantly best to make use of a Countersink Drill Bit with a body size that carefully matches that of the screw head; utilizing one also slim will not produce a large sufficient Countersink Drill Bit to approve the screw head, as well as utilizing one also broad risks of developing a crater-sized Countersink Drill Bit that entirely ingests the screw.

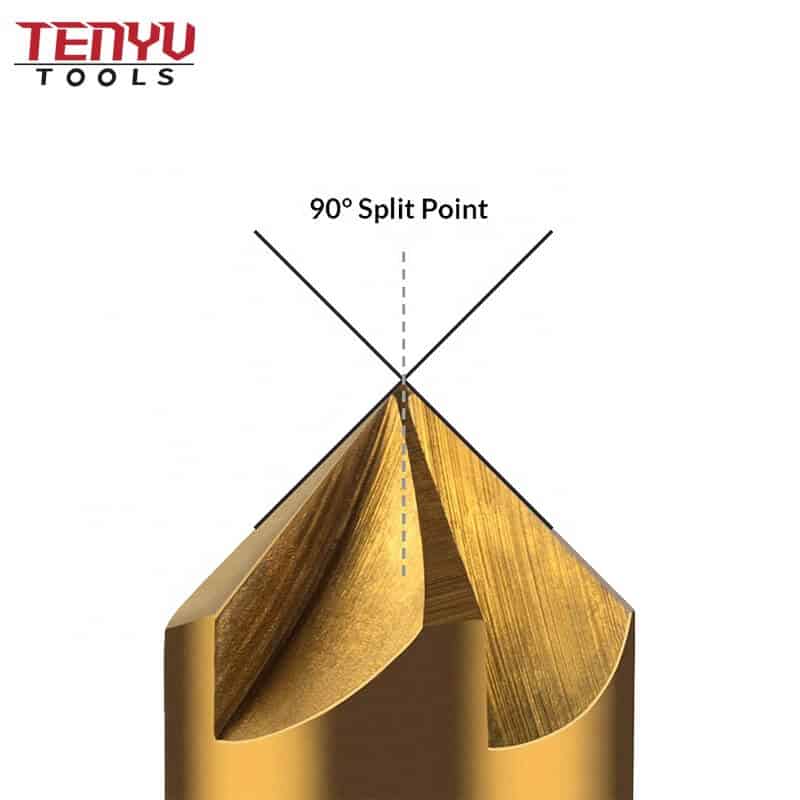

Getting the Angle

Given that possibilities are great that you’ll just utilize screws with 82 ° heads, does it make a distinction which Countersink Drill Bit you make use of as well as a purchase? Well, that depends. With the 90 ° Countersink Drill Bit, as a result of the 8 ° distinction, the extremely lower of the screw head reaches the timber initially, leaving the sides as well as the top of the screw in need of support. The screw should be additionally tightened up to bring the remainder of the head right into contact with the Countersink Drill Bit, developing a better pressure on the timber near the bottom. Basically, what you’re doing is by force extending the Countersink Drill Bit by overdriving the screw. With the 82 ° Countersink Drill Bit, all surface areas of the screw head reach the timber at the same time and also with an equivalent quantity of pressure.

Good sense will certainly inform you that matching the screw to the Countersink Drill Bit is the appropriate means to go. This is specifically real with wood, as completing the screw tighter in an initiative to appropriately seat the screw right into the Countersink Drill Bit places a great deal of anxiety on the head– try it with a brass screw, as well as the head will likely break off. For wood, matching the Countersink Drill Bit is constantly best. For softwood, nonetheless, not almost as much stress and anxiety is produced when seating an 82 ° screw in a 90 ° Countersink Drill Bit, and also the distinction might be undetectable.

Screws with 90 ° heads are made to the ISO Standard; they’re typically statistics and also even more typical overseas. Many identified in North America is the Unified Thread Standard of 82 °, which matches practically all woodworking screws you may experience in the U.S. as well as Canada. Nonetheless, both criteria of Countersink Drill Bit Drill Bits are easily offered right here.

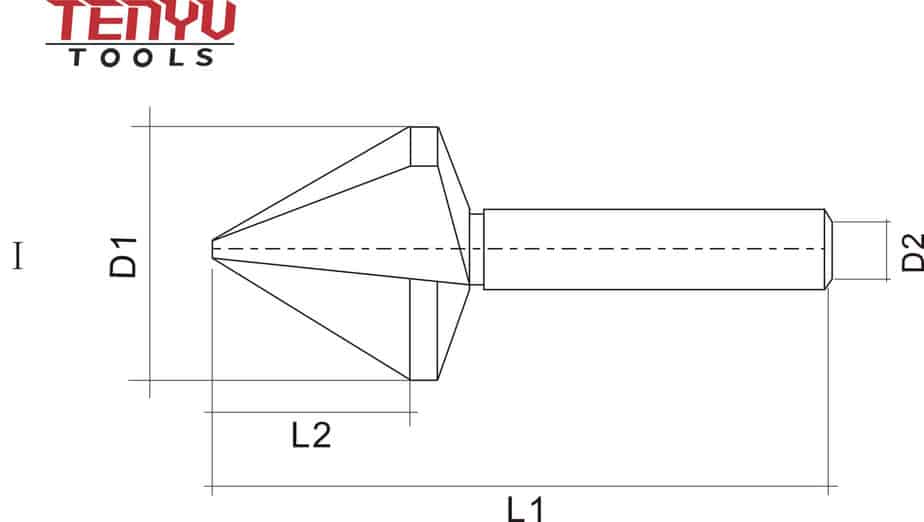

One of the most usual chamfer angles is 82 ° as well as 90 °, however, the majority of screws have an angle of 82 ° to make sure that is the angle that needs to be made use of in a lot of tasks. Countersink Drill Bit Drill Bits are readily available with cones formed to develop 6 unique chamfer angles– 60 °, 82 °, 90 °, 100 °, 110 °, and also 120 °– made to match a specific screw’s head angle.

Team Effort

They resembled arrowheads. There was absolutely nothing flexible concerning these– you either had the appropriate dimension or you really did not– as well as the Countersink Drill Bits and also openings they made weren’t much to consider, however, they got the job done rapidly as well as in a solitary action. They are marketed by the thousands, and also possibilities are great that any individual that’s been woodworking for a couple of years has a pair rattling around the all-time low of a tool kit someplace.

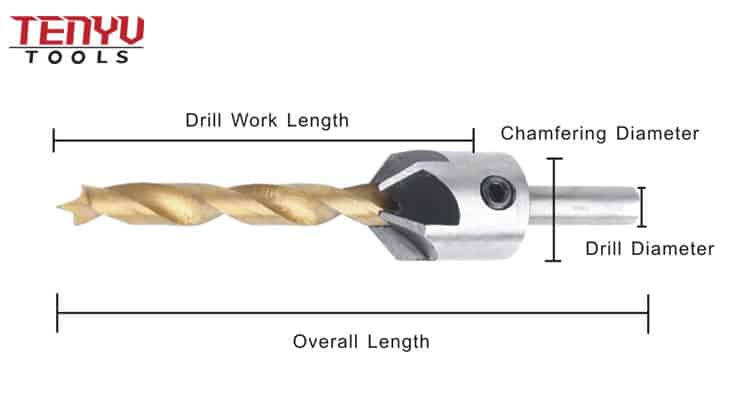

With the bits I’ve defined thus far, Countersink Drill Biting is a two-step procedure: pilot opening initially, adhered to by the Countersink Drill Bit. It’s reliable, yet time-consuming. Nonetheless, a wide array of mixed Countersink Drill Bit, do both jobs at the same time. Passing a number of names– Countersink Drill Bit drills, pilot screw Countersink Drill Bits and also piloted Countersink Drill Bits are simply a couple of– these bits cover a fluted Countersink Drill Bit around a flexible drill bit. (Crosshole Countersink Drill Bits aren’t made use of for these.).

It’s unusual to locate the old-style level steel piloted Countersink Drill Bit bits, however, they are fantastic for piercing Countersink Drill Bits rapidly (if inefficiently). The initial suggestion for these was around years ago with piloted Countersink Drill Bits constructed from a solitary item of level steel with completions rolled to develop a shank.

Flip-style Countersink Drill Bits have 2 ends one to drill the pilot hold as well as establish your Countersink Drill Bit, after that make use of the various other end to drive the screw. Today’s variations generate much better outcomes as well as are even more functional. Designs differ, yet each jobs is essentially similar.

Virtually every significant device producer that provides drills (in addition to a couple of that do not) creates fundamental, cost-effective mix Countersink Drill Bits of this kind. A lot of these are created in a “flip” design, with a double-ended cutter. You can drill both pilot opening as well as Countersink Drill Bit when it’s snapped onto the driving body in the Countersink Drill Bit set. Break the Countersink Drill Bit off, turn it around as well as break it back in to subject the proper vehicle driver bit to establish the screw.

Each Countersink Drill Bit is actually a mixing device, and also it contains a different drill bit focused in a through-hole in the body of the Countersink Drill Bit and also kept in area by either a collet or a setscrew activity of the Countersink Drill Bit body. The drill bits can either be conical or straight, their boring size flexible just by loosening up the setscrew or collet, gliding the drill bit to the preferred size and also retightening.

A lot of these Countersink Drill Bits can be utilized with a quit collar that establishes the deepness of the Countersink Drill Bit, and also a lot of can be found in collections that consist of different dimensions of matched Countersink Drill Bit as well as drill bits to suit the screws being made use of.

Modern Countersink Drill bits consist of the Rockler Pro Tapered Countersink Drill Bit, the CleanStop Countersink Drill Bit from Woodworker’s Supply, and also the Jack Bunny from Jack Bunny Device.

For reducing activity, there are 2 extra-long grooves that prolong up the Countersink Drill Bit body to assist expel chips via the deepness quit. The three-piece collection costs around $60, however, each Countersink Drill Bit is additionally offered separately, with # 5 as well as # 12 Countersink Drill Bits likewise offered.

The CleanStop shares a comparable set of lengthy grooves for chip ejection, yet it makes use of straight drill bits as opposed to tapered. 4 mix Countersink Drill Bit sized for # 6, # 8, # 10, as well as # 12 screws, can be found in the collection, yet just 2 deepness quits are consisted of: they should be shared amongst the 4 Countersink Drill Bit. The deepness quits are distinct and also include a two-piece layout with a polymer cap connected to the front of the steel quit. When it calls the work surface to aid protect against shedding the job or ruining surface area, the cap rotates easily yet quits. The primary shank is a 1/4″ hex layout. The four-piece collection costs around $60, yet Countersink Drill Bit is likewise marketed separately.

The established consists of the exact same 4 dimensions as the CleanStop, yet it makes use of a solitary body. Each Countersink Drill Bit is a different collet that screws right into the driving body, tightening up on the drill bit as it’s implemented. Business finishes sporting activity 4 brief grooves that do not prolong past the deepness drop in common usage. A solitary brass deepness quit is consisted of for the driving body.

The Countersink Drill Bit is a “quick-change” mix, making use of different drive shanks showing off both Phillips as well as square-drive ends. Being used, you drill the pilot opening as well as Countersink Drill Bit, after that simply breaking the driving body off the shank as well as drive the screws home in a fast one-two activity. The collection, which includes a set of wrenches for tightening up the collet-style cutters, 2 double-ended chauffeur shanks as well as an alluring ring for the motorists, costs around $58 since 2011. All 3 collections consist of a storage space situation, in addition to Allen wrenches. Substitute drill bits are offered for all.

Each has some distinct functions. The Pro Tapered is available in a trine full Countersink Drill Bit mixes, sized for # 6, # 8 as well as # 10 screws.

The bits are perfectly tapered to match the account of conventional woodworking screws, and also each drill bit has actually a squashed shank for safe locking with the setscrew. A deepness quit with 2 setscrews is consisted of for every bit, and also these Countersink Drill Bit Drill Bits have the biggest primary shank of 3/8″.

Other Countersink Drill Bit Styles

A customized Countersink Drill Bit in addition to a spherical tenon cutter and also drill develops completely seated mortise-and-tenon joints. Although there’s not constantly a great deal of ask for it in numerous woodshops, there’s a customized Countersink Drill Bit for making rustic log furnishings with rounded mortise-and-tenon joinery.

When an opening (the mortise) has actually been pierced to approve the round tenon of a furnishings part, these wedge-shaped Countersink Drill Bit conveniently taper the top of the mortise to specifically match the conical form of regular round tenons. The mortise-and-tenon joint companions completely for an extremely solid link. These Countersink Drill Bits are usually utilized with a durable drill.

You can make standard Countersink Drill Bits with a portable device, all they are a comfortable-to-grip manage with a Countersink Drill Bit snapped onto one end. Not all Countersink Drill Bits call for a drill, nevertheless. Hand Countersink Drill Bits include a deal with comparable to a screwdriver’s, with specific Countersink Drill Bit that break right into the front. Initially, drill your opening and after that, with a couple of spins, you have a standard, no-frills Countersink Drill Bit all set to approve the screw. They’re exceptional to maintain within arm’s reach or stowed away in the tool kit for making a fast Countersink Drill Bit or 2 without putting in the time to bring your drill as well as normal Countersink Drill Bits. These men do take a little bit of muscular tissue power, nevertheless, and also your wrist will certainly obtain its workout if you make numerous loads Countersink Drill Bits in oak with among these. However, for a fast one-off Countersink Drill Bit, they can not be defeated.

Using Countersink Drill Bits

The screw will certainly stay pleased of the surface area; go also deep and also the screw will certainly seat as well superficial if you do not drill the Countersink Drill Bit deep sufficient. With usage, you’ll rapidly obtain the feeling of certain Countersink Drill Bits, yet up until after that it’s smart to readjust all your setups (drill bit deepness, Countersink Drill Bit dimension, deepness quit area) as well as make an examination drill right into an item of scrap prior to piercing the actual work surface.

When Countersink Drill Biting, rate isn’t constantly your good friend. Exploration also quickly can result in too-large or too-deep Countersink Drill Bits, specifically in softwood. Broadband is likewise among the primary root causes of “babble,” a Countersink Drill Bit with a ragged edge as well as an internal surface area that is chewed out in an undulated pattern. For conventional conical timber screws, a Countersink Drill Bit with a conical drill is practically the most effective to utilize. Straight timber screws, such as those common black screws from the housing facility, job efficiently with straight drill bits. Nevertheless, in many usages other than in the hardest of woods, the sort of drill bits utilized in Countersink Drill Bits are compatible. In softwood, the distinction is minimal.

Maintain a close eye on the drill bits in your mix Countersink Drill Bits. Like any kind of a bit, they are reduced inefficiently when boring. Eliminate them as required as well as change them. Almost all Countersink Drill Bit producers make substitute bits that are simple to exchange in. Very same goes with the reducing sides of the Countersink Drill Bit itself. Develop them as needed or change them. Once more, all the producers provide substitutes. (In some instances, the substitute cutters are marketed along with brand-new drill bits.).

A lot of contemporary piloted countersinks are both depth-adjustable as well as have bits that are detachable for simple cleansing, developing, as well as a substitute. When utilizing a Countersink Drill Bit is to match the dimension properly to the screw being utilized, the most crucial point to maintain in mind. This goes with all facets of both the pilot opening as well as the Countersink Drill Bit itself. A too-large Countersink Drill Bit will certainly ingest the head of a screw in what will certainly appear like a moon-sized crater; a too-small Countersink Drill Bit will not fit the screw head, and also by force driving the screw in can tear the timber fibers around the Countersink Drill Bit.

Other Uses for Countersink Drill Bits

Mentioning deepness quits, take care with them. There’s no requirement to ram that Countersink Drill Bit down right into the work surface till the deepness quit bangs to a quit. All that will certainly obtain you are a ruined surface area. And also if you do not quit piercing quickly sufficient, the rotating deepness quit can quickly shed the timber surface area too … yet one more factor to stay clear of high-speed Countersink Drill Biting. One of the most effective methods to make a Countersink Drill Bit is to relax, as well as reduce the drilling rate as the quiet nears the surface area. When it just barely kisses the timber, you’re done. It’s most likely that after you obtain made use of to just how a specific Countersink Drill Bit jobs, you’ll leave the deepness drop in its instance. As soon as acquainted, you’ll have the ability to inform the proper deepness naturally.

Among the most significant comforts an excellent Countersink Drill Bit gives is having the ability to drill a pilot opening and also the appropriate Countersink Drill Bit, as well as concurrently placed both at the end of a much deeper opening that will certainly approve a wood plug. These deep Countersink Drill Bits are often described as “counterbores,” however that’s practically not quite exact.

You can make deep Countersink Drill Bits quickly by establishing the Countersink Drill Bit’s deepness quit permitting the Countersink Drill Bit to drill even more deeply right into the work surface. Make certain to determine the dimension of your plug to ensure your Countersink Drill Bit’s body will certainly make the right-size opening. Similarly, establish your deepness quit thoroughly. As pointed out previously, a fast examination drill in scrap is constantly a great concept when making changes to Countersink Drill Bit collections.

There’s one last job at which Countersink Drill Bits stand out, as well as it has nothing to do with timber: they are the fastest, most effective method to deburr a fresh pierced opening in steel. You may not believe there’s a great deal of requiring that in the woodshop, yet reconsider. Boring openings in joints, steel angles, jig parts, cast-iron for table accessories, rack braces and so on all leave an undesirable– as well as alarmingly sharp– burr around the side of the hole. One fast touch with a Countersink Drill Bit eliminates this burr. It’s finest not to utilize your normal woodworking Countersink Drill Bits for this job, nonetheless. Rather, get a number of inexpensive, one-piece fluted Countersink Drill Bits just for the function. (They make pricey Countersink Drill Bits for steel boring, however, for periodic deburring, the least expensive you can discover will certainly suffice.) Maintain them with the drill bits you usually utilize for steel, and also you can not fail.