Concrete Grinding Disc

- Your Trusted and Reliable Concrete Grinding Disc Suppliers

- You get a high-quality, durable concrete grinding disc.

- All Tenyu Tools products are made from the highest grade materials.

- Power tool accessories are manufactured using state-of-the-art equipment and tools.

- Tenyu Tools use cutting-edge technology to ensure excellent craftsmanship.

- You get access to different power tool attachments and accessories.

- All products are covered by a reasonable warranty.

- You can have your grinding discs customized to promote your business brand.

- You get exciting deals and discounts as a Tenyu Tools partner.

- They can handle your bulk orders.

- You get the assurance of fast and efficient delivery of your orders, wherever you are in the world.

Tenyu Tools Offer Industrial Quality --Concrete Grinding Disc

A concrete grinding disc is an abrasive tool that helps you reveal a smoother and more polished surface.

It is a circular expendable wheel or disc that is made from solid steel or aluminum material.

The grinding ability comes from the compressed or bonded coated abrasive materials.

It makes handheld or walk-behind concrete grinders perform their basic functions.

To ensure excellent results, it is necessary to find the ideal size and type of concrete grinding disc.

These factors also determine the disc rotation speed to get the job done.

Features

The crucial role of a concrete grinding disc in removing imperfections is undisputed.

The abrasive used for the disc determines the following:

- Hardness

- Strength

- Impact resistance

- Fracture toughness

Most handymen and masons use super abrasive materials like diamond and tungsten-carbide.

Both materials are known for their durability and high-performance.

Another important component of the grinding disc is the grit.

- Fine grits can help you create smooth and fine finishes.

- Coarse grits produce not so smooth surfaces.

Take note that all concrete grinding discs have expiry dates.

Make sure to check the label or the product itself to see when it will expire.

Proper disposal of damaged and expired discs is a must.

Product Applications

The concrete grinding disc has multiple uses.

- It grinds down concrete materials.

- It removes sticky tile glue and vinyl blue.

- It breaks down industrial buildups, dirt, grease, and other contaminants.

- It opens the pores of the concrete surface for easy removal of rust, paint, and coating.

- It levels up uneven concrete slabs or high spots.

Investing in a high-quality set of grinding discs is imperative if your business involves a lot of concrete grinding.

The right concrete grinding disc can deliver your desired surface such as:

- Rough surface

- Smooth, polished, and finely densified surface

- A surface that is suitable for slip protection grip or glue application

This versatile tool attachment can grind and polish almost all kinds of concrete materials.

It can be used for both interior and exterior concrete materials.

Related Products Mention

A trusted supplier of the concrete grinding disc is important in business.

Tenyu Tools is your best choice if you aim to scale up your distributorship.

They have different types of grinding discs for various applications.

As one of the leading concrete grinding disc suppliers in China, Tenyu Tools provide high-quality products.

They offer different types of drill bits, saw blades, and a variety of non-standard tools and accessories.

Your chance to make your business more dynamic is now.

Tenyu Tools got your back when it comes to supplying premium products.

Call them now for partnership deals and enjoy the privilege of accessing their premium products at discounted prices.

Tenyu Tools can handle your bulk order of concrete drilling disc and other power tool accessories.

So, what are you waiting for?

Call Tenyu Tools now.

- Manufacturing Machine for Concrete Grinding Disc

- Concrete Grinding Disc Using

The Ultimate Concrete Grinding Disc FAQ:

The concrete grinding disc is crucial to people whose works involve grinding concrete materials.

This is one grinding accessory that you cannot do without.

A concrete grinding disc or wheel helps you cut or grind the surface excellently.

To get the grinding job quickly, you need high-quality discs.

But before heading out to the nearest store or ordering online, best to check out this guide.

It has all the information you need to know about a concrete grinding disc like its types, features, uses, benefits, and proper care.

If you are in a distributor business and looking for the best concrete grinding disc suppliers, it helps you find one.

What is a Concrete Grinding Disc?

Concrete grinding is necessary to prepare for flooring purposes.

It uses an abrasive tool that houses a concrete grinding disc.

The concrete grinding disc does the trick and reveals a smooth finish that allows you to install the flooring.

It helps you polish and removes unwanted materials from the concrete slab.

This circular expendable disc makes various grinding, polishing, and cutting more efficient.

It can be made from aluminum or solid steel with bonded particles to the surface.

The bonded or compressed coated abrasive materials do the grinding.

A premium quality concrete grinding disc gives you a smooth, clean, and even level surface.

This sturdy cutter can also be used for materials like gemstones, marbles, and more.

Whether you are using a handheld grinder or a specialized floor grinder, the right disc gets the job done.

What are the Uses of Concrete Grinding Disc?

This horizontally rotating concrete grinding disc can perform different tasks.

The rotary action of the disc removes materials to about 1/8 inch.

It leaves a smoother and more polished profile, without abrading the surface of the material.

Concrete grinders have multiple uses and are ideal for various applications.

- leveling high spots or uneven concrete slab, eliminating the need to cover or replace it

- grinding down concrete material, exposing aggregate that offers a unique polished look

- removing stubborn vinyl glue or tile glue

- opening the pores of the concrete for easy removal of coating, paint, and rust

- breaking up deposits of industrial contaminants, dirt, and grease

The key to the grinder’s versatility is the attachment or the concrete grinding disc.

It is necessary to find the right type and grit to suit particular applications.

Investing in a variety of discs and other attachments will help you complete different tasks.

The common attachments include:

- diamond-segmented tools for removal of thin coating and for profiling work

- tungsten-carbide inserts to remove rubber deposit, resin, adhesives, paint, tar, industrial buildup

- silicon-carbide stones that provide rough finishes, level high spots, and smooth trowel marks

What Kind of Finish Does the Concrete Grinding Disc Give?

The finish you get depends on your objective and concrete grinding disc.

There are three options to choose from:

- smooth, polished, and finely densified surface

- rough surface

- a surface that is suitable for slip protection grip or glue application

The sophisticated and sleek surface is made possible by a concrete grinder with a diamond attachment.

This concrete grinding disc works excellently on various rough surfaces, leaving a smooth finish.

Can All Surfaces Be Polished by the Concrete Grinding Disc?

The answer is yes.

A concrete grinding disc is a heavy-duty abrasive grinding tool that can shear off unwanted layers.

It can remove glues or imperfections effectively.

With the help of a concrete grinding disc, your grinding tool works powerfully.

Almost all pre-existing concrete materials can be smoothed and ground down with grinding discs.

However, the effectiveness of concrete grinding is determined by the age of the concrete slab.

The older the slab, the easier for the concrete grinding disc to grind or polish the surface.

Another factor to consider is the strength of your concrete material.

Is it soft or hardened composite?

You also need to check the overall quality of the material if it is cracked or porous concrete.

All these factors affect the performance of your concrete grinding disc.

Like interior concrete, your exterior concrete flooring can also be polished.

But, there are some variables you need to watch out such as:

- Water damage

- UV radiation exposure

Both factors are detrimental to the application of polyurethane or epoxy.

You also need to consider the safety of everyone because concrete polishing can make your floor slippery.

What Kind of Concrete Grinding Disc Works Best for Various Applications?

For walk-behind concrete grinders that work best for floor and slab surfaces

- A single-disc can cover a width of 10-12 inches, which is ideal for small and restricted spaces.

- A dual-disc grinder covers 20 inches or more working width.

- A multiple-disc grinder is perfect for high-production grinding and large slab surfaces.

For handheld grinders that suit tight working areas like corners

- Smaller discs with a grinding diameter of 5 to 12 inches are ideal.

They can grind concrete countertops and remove bumps, graffiti, and form marks.

Disc rotation speeds vary from 250 to more than 3,000 revolutions per minute (RPM).

What are the Different Types and Sizes of Concrete Grinding Disc?

A concrete grinding disc comes in a variety of configurations.

You can find one for a handheld angle grinder or specialized tools for worktops and countertops.

Concrete grinding disc suppliers also have specific discs for purpose-build concrete floor grinders.

These types of grinders require more heavy-duty grinding discs to handle the higher sliding friction.

The diameter of a concrete grinding disc varies from one inch to 20 inches.

In terms of thickness, it ranges from 0.035” to ½”.

The largest concrete grinding disc can cut through concrete and metal materials.

The smallest grinding discs are ideal for minor projects.

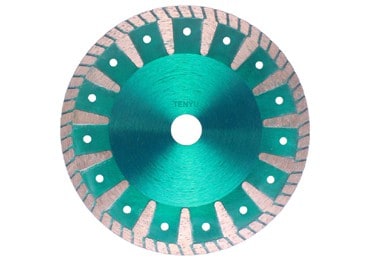

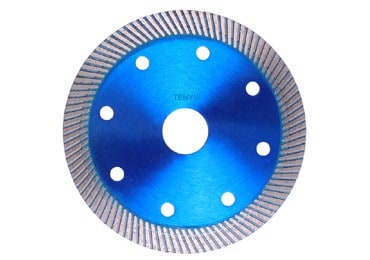

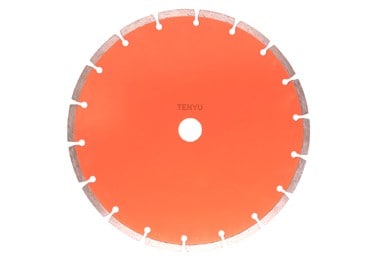

Different types of grinding discs include:

(insert figure 2 image here)

- Diamond disc

It is the best grinding disc for sturdy materials like concrete, precious stones, and carbide cutting tips.

This disc has industrial diamonds that are bonded to its periphery.

- Cylinder disc

Masons use this type of concrete grinding disc to make flat surfaces.

It suits vertical or horizontal spindle grinders.

- Straight disc

It is the kind of concrete grinding disc you use to create slightly concave surfaces.

It is useful for making cylindrical, centerless, and surface grinding jobs.

This disc can create a slightly concave surface.

- Tapered disc

You can use this type of disc to grind threads and gear teeth.

This flat-face disc tapers toward the center and is thicker at the hub.

- Straight cup disc

It delivers an extra radial grinding surface.

- Dish cup disc

This disc is good for cutter grinding and jig grinding.

It is used to grind in crevices and slots.

- Saucer disc

It helps you maintain saw blades and grind milling cutters or twist drills.

What are the Components of a Concrete Grinding Disc?

The four fundamentals of the concrete grinding disc are:

- Surface area

The surface area of the segment determines the level of speed or aggression.

The larger the area, the slower or less aggressive the disc becomes.

More aggressive and less segment concrete grinding disc delivers a less polished surface.

The output is a not-so-smooth surface with lots of scratches.

Discs with more segments bring a smoother surface.

- Segment shape

The segment shape of your concrete grinding disc influences its dispersion characteristic.

A tapered shape delivers better dispersion when it is oriented in the correct direction.

The shape also affects the aggression or removal speed of the concrete grinding disc.

- Segment bond

The segment bond suspends the grits from falling out into the surface.

It works to keep the polycrystalline diamonds from wearing away.

Diamond segments are gradually revealed through grinding friction.

Once completely exposed, the diamonds split and shatter to create a sharp grinding surface.

- Grit

The final part of the concrete grinding disc is the grit.

- 30 to 40 grit is the coarsest

- finer than 40 grit creates a smooth surface

- 60 to 80 grit disc is ideal for polishing

Why is Grit Important for a Concrete Grinding Disc?

The grit corresponds to the individual size of the grain in the concrete grinding disc.

It refers to the number of openings in every linear inch in the screen.

Lower numbers (9, 15, 23) mean that the disc has a coarser grain that suits larger materials.

The coarse grains in the concrete grinding disc also offer rapid removal of materials.

It is applicable when you do not aim for a fine finish.

The higher numbers of grit (75, 150, 180) translate to the smaller openings in the final screen.

The fine grit discs deliver fine and smooth finishes.

Why Do You Need to Consider the Abrasive Used to Make a Concrete Grinding Disc?

Abrasives are essential factors when you are searching for the best concrete grinding disc.

They come in different varieties with unique properties that indicate the following:

- Strength

- Impact resistance

- Hardness

- Fracture toughness

Concrete grinding disc suppliers usually use two kinds of abrasives during manufacturing.

- Conventional abrasives

- Silicon-carbide

A silicon-carbide concrete grinding disc is an economical choice.

It helps you create rough finishes, smooth trowel marks, and level high spots.

It suits concrete, cemented carbides, marble, and other stone materials.

- Aluminum oxide

- Ceramic

- Super abrasives

- Diamond

A concrete grinding disc with diamond properties is perfect for difficult and tough surface materials.

It can remove thin surface coatings with greater efficiency and speed.

Diamond-segmented abrasive suits applications for granite, stones, marbles, and cemented carbides.

It is ideal for profiling applications and removing minor imperfections on the surface.

The diamond segments are bonded to the backing plate.

They are embedded in a resin or metal matrix and sit on the surface.

As your tool grinds, the matrix wears away gradually exposing new diamonds.

- Tungsten-carbide

The concrete grinding disc with tungsten-carbide abrasive strip heavy buildups.

It is capable of removing stubborn adhesives, paints, and more without digging.

The disc works like a scraper, removing unwanted elements to thicker materials.

- Cubic boron nitride

Masons and contractors who work on concrete surfaces prefer using super abrasive discs.

When deciding whether to use a diamond or a tungsten carbide, think about these main factors:

- Type of material

- Thickness and strength of the surface’s mechanical bond

For materials that can be cut using a knife, choose tungsten carbide.

Diamond segments suit a thinner coating of not more than 1/16 inch.

Use diamond segmented concrete grinding discs with a hard bond for soft materials.

A soft-bonded matrix is best for grinding hard materials.

How Do You Choose the Best Concrete Grinding Disc?

With numerous grinding discs available on the market today, you need to know what kind of disc you need.

You should consider the design of your machine or tool in choosing the right set of grinding discs.

It is imperative to remember that cheaper discs do not guarantee durability and long-lastingness.

Substandard abrasives used to manufacture the concrete grinding disc can affect the production process.

Every concrete grinding disc has a set of properties and characteristics.

The functionality and performance of the concrete grinding disc depend on its vital elements.

During the selection, check out the following elements:

- Bond strength

The bond holds the grain and abrasive spacing of the concrete grinding disc.

The grain spacing typically spans from 1 being the densest up to 17 which is the least dense.

The strength of the bond refers to the grade of the bonding material.

It can be classified into A to H (soft), I to P (moderately hard), and Q to Z (hard.)

The soft-bonded discs tend to release grains quickly, making the wheel wear out fast.

The hard-bonded concrete discs tend to cause glazing that makes the grains wear out.

The grade of the concrete grinding disc will determine the following:

o grinding depth

o wheel speed

o maximum and minimum feed rates

o coolant flow

- Structure

The open-structure concrete grinding disc cuts more freely, deeply, and broadly with less coolant.

It also plays a significant role in the quality of the finish.

Does a Concrete Grinding Disc Have an Expiry Date?

Yes, your concrete grinding disc has an expiry date.

Not all people are aware of this important information.

The expiry date appears on the concrete grinding disc in month and year format.

It usually appears on the center ring of the disc.

All concrete grinding disc suppliers imprint the dates to comply with the regulation of the industry.

The expiry of the concrete grinding disc is usually three years from the date of manufacturing.

Some smaller grinding discs have expiry dates on the product label.

The reason behind the expiry date is the resin that is used by the manufacturers.

The resin helps to bond the grinding abrasives.

As time goes by, it begins to absorb moisture that causes deterioration in the concrete grinding disc.

Check the imprinted expiry date of your concrete grinding disc regularly.

Using an expired disc for grinding poses major risks to the person handling the tool or anyone around.

Why Correct Usage Is Necessary When Using a Concrete Grinding Disc?

Injury and accident prevention in the work site begins by using the concrete grinding disc properly.

Although the grinding tool has safety features, correct usage promotes better protection.

When operating a grinder of any form, always use personal protective equipment (PPE) such as:

- Safety goggles

- Safety gloves

- Dust mask

- Ear defenders

- Protective clothing

- Safety shoes

They protect you from the flying sparks that are formed during the grinding.

Moreover, the silica dust from the grinding process is toxic to your lungs.

Always follow the necessary precautions for personal safety.

Safety procedures should be observed.

- Organize the wiring to avoid serious electrical incidents.

- Make sure the concrete grinding disc is completely static in the grinder to prevent accidental spinning.

- Before plugging the grinder into the power supply, check if it is switched off.

- Operate the tool according to the instructions in the user manual.

- Use the appropriate concrete grinding disc for the application.

- Always keep the grinder’s safety guard at all times during the grinding.

- Use your two hands when grinding to ensure safe operation.

- Before using or replacing parts, always inspect the grinder.

- Keep your focus during the grinding process and take proper breaks.

How to Keep the Concrete Grinding Disc in Good Condition?

To keep everyone safe on the job site, it is important to conduct an inspection before and after using your tools.

A ring test is the best way to check if your concrete grinding disc has cracks or defects.

- Make sure that the disc is dry and free from any dust.

- Hold the disc through the bore at about a 45-degree angle to the surface.

- Lightly tap the disc using a non-metallic instrument like the handle of a screwdriver.

- Strike the periphery of thick and large discs, rather than the side part.

- Rotate to test the other side of the disc.

A clear “ring” sound means that your concrete grinding disc is in top condition.

When it is cracked or defective, you get a dense, unclear, muffled “ring” sound.

- Rotate and repeat the test to the other side of the concrete grinding disc.

- Do not use the damaged concrete grinding disc anymore.

Concrete grinding disc suppliers recommend performing the test before mounting it on the tool.

How to Store Your Concrete Grinding Disc?

The way you handle and store your concrete grinding disc affects its performance and longevity.

When stored and used properly, the abrasives would perform excellently until their expiry dates.

Neglecting to observe the recommended ways to store your tool attachments can compromise safety.

Abrasive products require careful storage and handling.

For all your bonded or coated abrasives, observe the following conditions:

- The area should be dry and frost-free.

- Keep the concrete grinding disc away from damp and cold areas.

- Excessive humid or dry storage can cause deformity.

- Keep the attachment in the room with an ideal relative humidity of 45°C.

- Store the disc in a room with a temperature that ranges from 18°C and 26°C.

- Avoid exposing your concrete grinding disc to direct sunlight or high-temperature variations.

If you have storage racks, drawers, or bins for your grinding discs, keep similar types in each section.

- To store super abrasives, store them using the original packaging.

You can use protective separators to prevent contact.

- Soft-grade discs/wheels should be placed rim-to-rim- and base-to-base.

This prevents cracking of walls and chipping of edges.

- Hard-grade and thick discs can be stored on the periphery.

Where to Find Trusted Concrete Grinding Disc Suppliers?

A reliable supplier of the concrete grinding disc can help you grow your distributorship business.

One of the best suppliers of power tool accessories and attachments in China is Tenyu Tools.

They have been partnered with many importers, wholesalers, and distributors.

Tenyu Tools is now serving North America, Eastern Europe, Northern Europe, and China’s domestic markets.

They offer a high-quality, durable variety of discs at very reasonable prices.

All Tenyu Tools products are made from commercial-grade materials and covered with a warranty.

What Advantages You Will Enjoy If You Get Tenyu Tools as Your Concrete Grinding Disc Supplier?

As one of the biggest and most popular China-based manufacturers of different grinding discs, Tenyu Tools is your best partner.

- You can easily grow your business and provide a huge supply to your own distributors.

- Tenyu Tools can handle your order of large volume and allow customization if necessary.

- They have the most modern production facilities of Tenyu Tools and cutting-edge technologies.

- You get to enjoy the fast delivery of your orders and other amazing deals that they give to their partners.

- All their products passed the strict quality standards of the manufacturing industry.

- The grinding discs are tested to ensure durability and long-lastingness.

If your goal is to upscale your business and try both the domestic and global market, Tenyu Tools got your back.

They offer a wide array of power tool accessories and attachments for different applications.

If you are interested in getting Tenyu Tools as a supplier of concrete grinding discs, call them now.

The sooner, the better for your business.

Now that you are more informed about the concrete grinding disc, you are more adept at picking the best ones.

If you have other questions regarding the product or about Tenyu Tools, don’t hesitate to call their hotline.