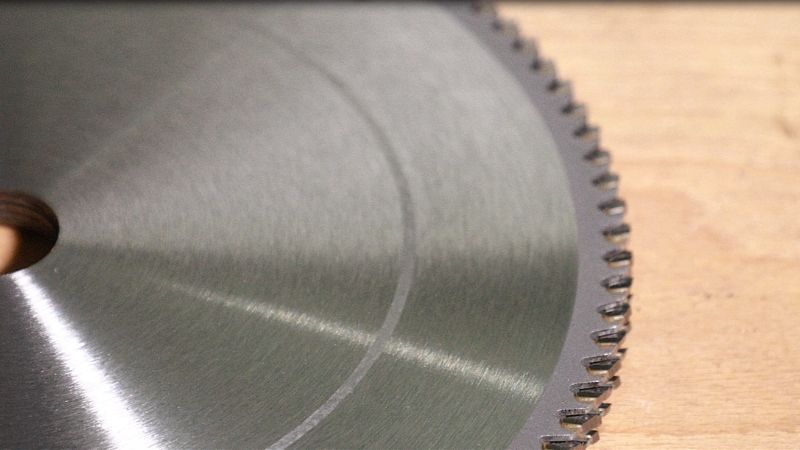

Wood Saw Blade

9 Inch 60 Teeth Carbide Circular Saw Blades for Wood

- High Precision, Low Noise, Sharp Teeth

- The teeth material is tungsten carbide provide excellent wear and heat resistance

- The positive cutting angle which provides fast and efficient removal of chips and swarf

- Special Coating can prevent wood circular saw blade rusty

- Wood cutter blade can use with Circular Saw, Miter Saw, Table Saw, Radial Arm Saw

- Product Details

- Factory

- Material

|

Production Description

|

||||

|

More Choice For You: Home > TCT Circular Saw Blade > For Wood

|

||||

|

Product Name

|

Tungsten Carbide TCT Circular Saw Blade Types for Wood Cutter Blade 9inch 60teeth

|

|||

|

Material

|

Teeth Material: Tungsten Carbide Body Material: 65Mn Steel

|

|||

|

Progress

|

Automatic Welded

|

|||

|

Teeth Type

|

ATB Teeth (FT Teeth, Trapezoid Teeth, ATB Teeth with Anti-kick Back, ATBR Teeth are available)

|

|||

|

Arbor Hole Size

|

All size is available upon request,such as 5/8”, 1” 20mm, 22.23mm, 25mm, 30mm, 35mm…etc

|

|||

|

Teeth Design

|

Teeth Number ould be adjusted upon request; Hook angle could be adjusted upon request

|

|||

|

Package

|

One piece in one PVC double blister, paper box or PVC Skin Card

|

|||

|

Features

|

1. This TCT Circular saw blades size is 9 inch. It is designed as general crosscut blades, suitable for cross-cutting softwood,hardwood, plywood, chipboard, multi-board, panels, MDF, plated&counted-plated panels, laminated&Bi-laminate plastic, and FRP. Providing a high degree of finish edge. The blades also can rip cut along the grain. 2. Incorporates an ATB (Alternating Top Bevel) offset tooth design, The angle of the tooth scores the surface of the wood in advance of the cut, cleanly cutting the wood fibers before the following teeth remove the chip. This provides for a much smoother cut, with much less chance of splintering the surface of the wood. 3. Tungsten carbide teeth provide excellent wear and heat resistance. The Cricle Saw Blades are for wood cutting.The positive cutting angle which provides fast and efficient removal of chips and swarf. 4. Fully hardened steel blade body – delivers accuracy and resists bending and deflection for true cuts.

5. Heattreat expansion slots allow the blade rim to expand and contract without warping for straight and accurate cuts, Wood cutter blade for smooth surface.

6.Equipment used with Circular Saw, Miter Saw, Table Saw, Radial Arm Saw, etc.

|

|||

| Product Size | |||||

| Diameter | Kerf | Plant Thickness | Arbor Hole Size | Teeth Number | |

| Inch | mm | mm | mm | mm | |

| 5″ | 125 | 2.6 | 1.6 | 20/25.4 | 24,30,36 |

| 6″ | 150 | 2.6 | 1.6 | 20/25.4 | 28,30,36,42,48 |

| 7″ | 180 | 2.6, 2.8 | 1.6, 1.8 | 20/25.4 | 32,36,42,48,54,56 |

| 8″ | 200 | 2.6, 2.8 | 1.6, 1.8 | 20/25.4 | 36,40,48,56,64 |

| 9″ | 230 | 2.8 | 1.8 | 20/25.4 | 40,48,54,60,64,66,72 |

| 10″ | 250 | 3 | 2 | 20/25.4 | 48,50,60,64,72,80 |

| 11″ | 270 | 3 | 2 | 25.4/30 | 48,50,60,64,72,80 |

| 12″ | 300 | 3.2 | 2.2 | 25.4/30 | 60,72,80,84,96 |

| 13″ | 330 | 3.2 | 2.2 | 25.4/30 | 60,72,84,96,100 |

| 14″ | 350 | 3.2 | 2.2 | 25.4/30 | 72,84,98,100,108 |

| 16″ | 400 | 3.5 | 2.5 | 25.4/30 | 80,96,112,120 |

| 18″ | 450 | 3.5 | 2.5 | 25.4/30 | 90,108,126,140 |

| 20″ | 500 | 3.5, 3.8 | 2.5, 2.8 | 25.4/30 | 100,120,140 |

| 22″ | 550 | 3.8 | 2.8 | 25.4/30 | 110,120,144 |

| 24″ | 600 | 4 | 3 | 25.4/30 | 120,144,150 |

| 26″ | 650 | 4 | 3 | 25.4/30 | 120,140,150 |

| 28″ | 700 | 4.2 | 3.2 | 25.4/30 | 120,140,150 |

| 30″ | 750 | 4.2, 4.6 | 3.2, 3.6 | 25.4/30 | 120,140,150 |

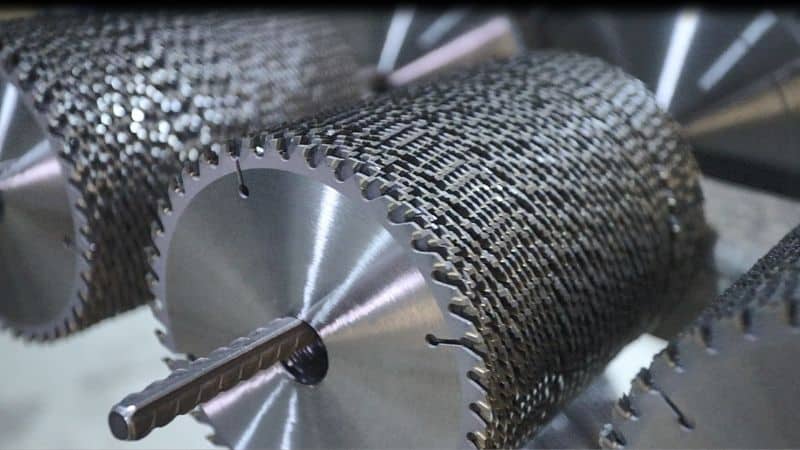

Factory

TENYU 9 Inch 60 Teeth Circular Saw Blades are carefully designed for cutting efficiency and fast. Tungsten carbide has a high hardness compared to other metals so the saw blade teeth can cut the wood easily. Wood circular saw blade grooves can reduce the noise. The saw blade coating can prevent rusty.

- Teeth Material: Tungsten Carbide YG8C

- Blade Material: 65Mn or 50# Steel

- Teeth Type: ATB Teeth

- Usage: Wood Cutting

Wood circular saw blades provide you a smooth cutting.

ATB tooth design, tungsten carbide teeth and special coating.

- Teeth Material: Tungsten Carbide YG8C

- Blade Material: 65Mn or 50# Steel

- Teeth Type: ATB Teeth

Related Products

Wood Cutting Blade – The Comprehensive FAQ Guide

There are a lot of wood cutting blades you can choose from in the market. There are those made with tungsten carbide, made with copper, steel, and other materials.

But what is the best wood saw cutter for your projects?

In this post, we will tackle everything you need to know about wood cutting blades. We’ll also be discussing where you can get the best quality of wood saw blades in the market.

What is a Wood Cutting Blade?

By definition, it’s a tool that you can use to cut, slice, and alter wood.

You can choose from different wood cutter types, such as plywood blades, dado blades, fine-tooth blades, and crosscutting blades.

What’s the Best Saw Blade for Wood?

There have been a lot of discussions about what the best saw blade is for wood.

But, among the most popular is the 40-tooth general-purpose blade. Every woodworker or a company involved in wood should have this type of wood cutting blade.

However, the best would still depend on the type of wood you’ll be working on.

Different Types of Circular Wood Cutter Saw Blades

There’s a lot of types of circular wood cutter blades you can choose from.

- Ripping Blades

- Plywood Blades

- Crosscutting Blades

- Finishing Blade

- General Purpose or Combination Blades

- Thin Kerf Blade

- Dado Blade

- Treated Wood

All of them have their uses and benefits; you should choose according to what you need.

What is the Best Tool to Cut Wood?

You can choose from a myriad of options of wood cutting tools.

Depending on your preference, there are manual tools and power tools; a wide range you can choose from.

The best tool you can use will be based on what type of material you’ll need to work on.

But, to give you a quick rundown of the most common tools used, here they are:

Manual Tools

If you were to use these tools, you wouldn’t need electricity or power to make them work.

Handsaw

Ideally speaking, handsaws are the most traditional type of tool you use to cut wood.

There are a lot of variations of handsaws; they’re objects where you’ll use your hand to work on wood.

The most common handsaws include:

- Crosscut Saw

- Bow Saw

- Coping Saw

- Hacksaw

- Two-Man Crosscut Saw

Chisels

Chisels are simply tools you can use for woodcarving. They’re often made out of steel with an edge shaped specifically for carving and cutting.

Those are just some of the most common tools you can use in cutting wood.

Now, let’s head onto those that need electricity or power.

Power Tools

From its term alone, power tools are tools that require power for it to work.

There are a lot of types and kinds of tools you can use to cut wood, but the most common include:

Chainsaw

Chainsaws are, perhaps the most traditional of all power tools. Being popularized by the horror movie The Texas Chainsaw Massacre, a lot of people knew what chainsaws are capable of.

You can use chainsaws for a lot of things, but the most common would be for cutting trees.

Circular Saw

Considered as the universal saw, circular saws are exactly what you think they are.

The blade is in a shape of circle with many teeth and you can use it for a lot of types of cutting.

Router

Routers are one of the most powerful wood cutter tools out in the market.

They’re what you’ll use if you want to create cabinets, and they’re known for the flexibility of their functionality.

They’re what you’ll use if you want to create cabinets, and they’re known for the flexibility of their functionality.

Materials Used to Create Wood Cutting Blades

You can employ different elements and materials in making blades for wood cutting.

But, the most common ones are:

- Regular Steel

- Stainless Steel

- Tungsten Carbide Tipped (TCT)

- Aluminum Oxide

Other types of abrasives and material are what you need to use for cutting metal, PVCs, etc.

What are TCT Circular Saw Blades?

TCT is short for Tungsten Carbide Tip and is common in manufacturing saw blades.

It’s a type of saw blade with durable and strong teeth that you can use to cut on many things. You can cut on rails, metal tubing and fitting, titanium, and many more.

TCT saw blades have tungsten carbide coating, which protects and provides the ability to cut through a wide range of materials – wood, among others.

What is a Saw Kerf?

The term “kerf” is what you use to identify the distance of teeth with each other.

Can You Cut Wood Using TCT Blades?

Yes, you can cut wood by using TCT blades.

The saw kerf does not promote wide differences; what you need to take into account would be the material you’ll be cutting.

Do All Wood Cutting Blades Have the Same Teeth?

No, in fact, you can choose from many different kinds of wood cutters.

You can choose from 24 teeth, 32t teeth, 40 teeth; going up to 60 and 80 teeth.

The teeth count has a difference – and it’s more relevant than you think.

More teeth mean a smoother and a faster cut for you; while fewer teeth mean more material would be taken and removed.

The Best Circular Wood Cutting Saw Blades

Out of all the many choices of wood cutting blades in the market, the top in our list include:

- Tenyu Tools Wood Cutting Saw Blade (Best choose)

- DeWALT Parent Title Circular Saw Blade

- Mibro Circular Saw Blade

- Oshlun Circular Saw Blade

- IRWIN Metal Cutting Circular Saw Blade

- Freud Tooth Diablo Ultra Fine Circular Saw Blade

Top Wood Cutter Suppliers and Manufacturers

You need to ensure that the manufacturer you’ll work with is known. Why? – It’s not just about popularity, it also is about quality and the discipline they have.

Among the wide selection of wood cutting blades, the best ones, according to people selection include: Among the wide selection of wood cutting blades, the best ones, according to people selection include:

- Tenyu Tools (Best choose)

- Dimar

- PILANA

- Freud

- AKE

There are a lot more manufacturers, but they’re the best known and considered as the top.

The only problem is that their rates and prices aren’t that friendly.

Different Sizes of Circular Saw Blades

You can choose from a wide range of sizes for your circular wood cutting saw blades.

But, that’s more than just looking for the size, it also has something to do with speed.

You can choose from the widest range of saw blades from 165 millimeters (mm) or 6 and ½ inches to 550 millimeters (mm) or 22 inches.

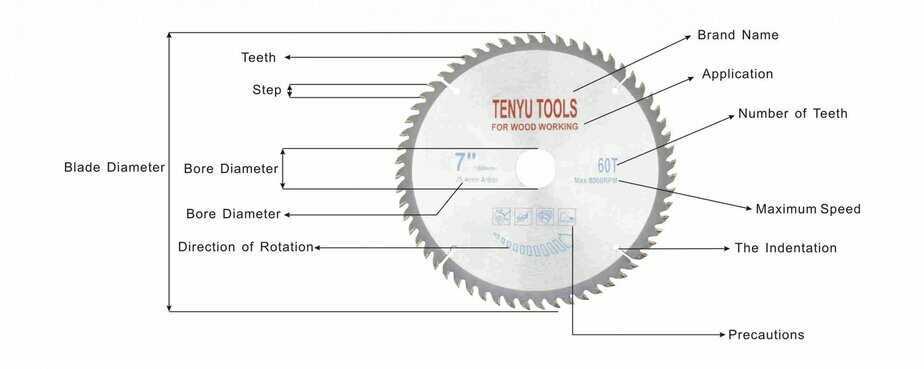

Parts of Circular Blades For Wood Cutting

Several manufacturers and companies might call it differently.

But, the most common parts that would never be taken include:

- Tooth

- Tooth Tip

- Gullet

- Bore

- Expansion Slot

Wood Cutters For Trees vs. Cutting Blades for Metal

A lot of people aren’t aware of this, but are there differences in wood cutting blades for trees and for metal?

Yes, you can’t just use what you intend to use for wood for metal.

For one, cutters with smaller and a higher teeth count are what you usually use with metal. In fact, even different types of metal require different blades.

Generally speaking, larger and fewer teeth is what you use in wood; but, then again, there are specific blades for different types and kinds of wood.

Using wood cutters in slicing metal can make the teeth break. When it does, it can impose danger to whoever’s working on it.

What Materials Can a Circular Wood Cutting Blade Work On?

You can use wood saw cutters for a wide range of wood types.

You can choose to use it for:

- Hardwoods

- Softwoods

- Pine

- Mahogany

- Red Oak

- Ash

In addition to that, you can also purchase specific types of cutters for other kinds of wood. You can use some wood cutting blades for cutting bamboo, ash, maple, and so on.

Where Can You Find Wood Cutting Band Saw Blade Suppliers You Can Trust?

Across the entire globe, only in China will you be able to find reliable and trustworthy suppliers.

Whether you need band saw blades for wood cutting, circular wood saw tools and materials – or any other kind of wood cutters, you’ll never see a shortage if you look in China.

Applications of Wood Cutting Saw Blades

When it comes to its applications, you may choose wood cutting blades for a wide range of uses.

Most people think that it’s only for construction, but, you can also use it if you’re in:

- Furniture Creation Industry

- Forestry Industry

- Shipping Containers

- Pulp and Paper Industry

- And Many More!

So long as you need to alter wood, you can find wood saw cutting blades useful!

Tips to Find the Best Wood Cutter Blade Manufacturers

It’s not unknown that China is a country home to a myriad of manufacturers of all materials. You can find a lot of suppliers for what you need here.

With that in mind, how do you go about finding the best manufacturer of saw wood blades?

Check Certifications

The first thing you have to do is to make sure if the manufacturer you’re eyeing on is legit. One way to figure this out is by looking for the certifications they have.

You’ll always have problems in choosing a wood cutting blade supplier without certifications.

Product Expertise

Is the manufacturer an expert in making the specific type of wood saw cutter blade you need? Can they produce sufficient amounts of products you’re looking for?

Knowing whether a manufacturer is skilled enough to produce the material you need is relevant. This can help you save a lot of time and money in perfecting the equipment you’re looking for.

Production Frequency

Not a lot of manufacturers can produce proliferate materials; this is why looking for a manufacturer that can produce materials in big amounts is as important as ensuring quality.

There are a lot of things you need to consider before you choose a manufacturer of wood cutting blades.

But, these are the top tips for you to properly select the supplier that you can trust.

Wood Saw Cutter Prices

The prices of wood saw cutter blades will depend on the make, the material, and the brand.

You really can’t have a specific estimate of how much it will be. However, to give you a rough estimate, it can cost you anywhere between $10 and $1,000.

Where Can You Get High-Quality Wood Saw Blades?

China is known to be the best country that houses manufacturers of all kinds.

Should you want the highest quality of wood saw blades, there’s no other company you can trust but us here at Tenyu Tools Co., Ltd.

We’ve been considered as the best manufacturer of steel and metal tools for many years. You can trust us to supply you with the wood cutting saw blades that you need!

Why is Tenyu Tools Co., the Best Wood Cutter Blade Manufacturer?

We’re considered as the best because our market has reached and expanded to areas in North America, Northern and Eastern Europe, and Australia.

Tenyu Tools Co., Ltd. has dominated the entire Asian market; and you can trust us to manufacture and produce the wood saw cutters that you are in dire need of!

Being the best wood cutting saw blade manufacturer, you can be sure that we have the right certifications. We have OSA certifications, topped with the standard for European work (EN13236).

Become one of our clients and enjoy the best wood cutting band saw blades you can get!

Tenyu Tools is China’s number one company in producing wood cutting blades.

You can trust us! We’re the country’s top manufacturer of screws, drill bits, blades, and more!

If you need wood cutting blades that can work on a wide range of woods, Tenyu Tools will deliver! Why should you choose the wood saw cutting blades that we offer?

Tenyu Tools’ Wood Cutting Blades

You can choose from our catalog of wood cutter blades, depending on what you need.

You can choose from the wide range of blades that we offer; we have 20 teeth blades, as well as blades that have 80 teeth! You can even get or purchase blades that have 100 teeth!

Tenyu Tools can help you manufacture the specific circular saw blades for wood cutting you need! Whether you need a 7-inch cutter or a 10-inch cutter, we got it!

You can use the saw blades for woodworking that we offer for a lot of things!

If you’re a woodworking business, or if you want to perform DIY wood furniture, and the like, you can bank and count on us!

Features and Benefits

While other manufacturers and companies offer blades that have the same structure, Tenyu Tools will never fail you when it comes to features and advantages.

Apart from these benefits, Tenyu Tools’ wood saw blade cutters can also be used with other equipment, including table saws, miter saws, radial arms, etc.

Applications of Our Wood Cutting Blades

There are a lot of businesses and companies that trust us for the wood cutters they need.

But, among the most common businesses and industries that approach us to include:

- Furniture fabrication industries

- Woodworking industries

- Construction and Structural industries

- Forestry

Other Products and Equipment We Offer

Tenyu Tools isn’t only focused on producing and manufacturing circular saw wood cutters.

In fact, we can also help you with drill bits (for wood and for metal), diamond, metal, and masonry cutters, and many more!

You can reach out to us here at Tenyu Tools via email! You can get high-quality wood cutting blades!

Get it at a fast and steady rate without compromising the strength, effectiveness, and efficiency of the tools!

In fact, we can also help you with drill bits (for wood and for metal), diamond, metal, and masonry cutters, and many more!

You can reach out to us here at Tenyu Tools via email! You can get high-quality wood cutting blades!

Get it at a fast and steady rate without compromising the strength, effectiveness, and efficiency of the tools!

Additional Content for Wood Cutting Blade/Cutting Blade

Finding the correct variant of wood cutting blade is something that’s not easy to do.

That’s why we’ve come up with this guide to help and to assist you on how you can purchase the best and the most appropriate wood cutting blade for your projects!

Can You Use a Wood Cutting Blade to Cut Concrete or Metal?

The short and simple answer is yes, you can use wood cutting blades to cut metal or concrete.

Although it’ll take more time if you do so, you will be able to cut it. In addition to the time, the life expectancy or the longevity of the cutting blade is also at risk of being damaged or broken earlier and easier compared to if you just use and utilize it for wood.

Most wood cutting blade manufacturers don’t recommend it, of course, because it’s dangerous. When it malfunctions, the bits or the fragments of the blade could shoot up through the sky.

Can You Get a Wood Cutting Disc For an Angle Grinder?

From the term, an angle grinder is a type of power tool you use to cut or grind tile, pavers, etc.

To answer the question, yes, you can use wood cutting discs or blades on angle grinders. Most wood cutting blade suppliers don’t just recommend it because accidents could possibly occur.

These accidents don’t just involve the breakage of the saw blade, but also health and safety-threatening accidents such as blades flying out of the grinder, the teeth chipping off and ricocheting, and others of the same kind.

What is the Cut Made by a Saw Called?

There are two (2) primary cuts wood cutting blades make and give, and it is the crosscut and the rip cut.

How are they different? Which one should you use? For this, you really don’t need to rely on your wood cutting blade manufacturer – this strategy or tip will really depend on what you need.

But, to help you with it further, here are some of the notable differences between them.

The Rip Cut is the type of cut that you make where the cut you’ll make is parallel or is equidistant to the workpiece’s grain direction. On the other hand, a Crosscut is a type of cut where the cut is made at the right angle fi the direction of the wood grain.

What is the Best Wood Cutting Blade?

According to many sources and wood cutting blade manufacturing companies, the best type of wood cutting blade is a circular saw blade.

They are, in fact the most typical type of blade you can use for woodworking. Due to the distinctive number of teeth on the blade, as well as the quality of how circular wood cutting saw blades are made.

But, of course, circular saw blades aren’t the only blades you can use. In fact, many wood cutting blade suppliers market too few types of other blades, too such as rip blades, crosscut blades, band saw blades, router blades, and many more.

For you to get the best and the highest quality of cuts, asking your wood cutting blade manufacturer would be a good way to start. But, there are a couple of things you can do to help you with the choosing as well.

That brings us to our next question, which is…

How Do You Select the Wood Cutting Blade For Your Table Saws?

Of course, the wood cutting blade you want to choose and select must be the blade that can give you the results you need.

You can’t blame the wood cutting blade manufacturer for what they’ll give you – but, you can ask them what you can get by simply telling them the results you’re looking to get.

For you not to waste time speaking with various wood cutting blade suppliers and manufacturers, you can follow this specific guide to choose the cutting blade you can use for your table saws.

Blade Size

Part of the first things you need to take note of would be the size of the blade. There are multiple sizes that you can choose from – most of which are identified via the diameter.

To give you an idea, most of the handheld saw blades manufacturers produce are within the range of 7 ¼ inch to 8 ¼ inch.

Table saws and stationary saws, on the other hand, have sizes that range from 10 inches t 12-inch wood cutting blades. There are certain models that are only 8 inches in size or diameter but they’re not efficient for heavy-duty woodworking.

However, wood cutting blade suppliers also produce and manufacture specialty blades that have sizes below or above that typical size.

The sizes are never constant – and most of the time, you can request for custom ones from your wood cutting blade wholesale manufacturer.

NOTE: Many people are wondering, but could smaller-sized blades be mounted and used for saws that are large in size? The simple answer is yes. You can do so – but, most wood cutting blade manufacturers wouldn’t advise this because of safety reasons. So long that it’s secured, you can use a smaller blade with a larger saw.

Wood Cutting Blade [Type]

After determining the size you’ll go with, you would then want to choose from the various types of wood cutting blades there is.

This would probably be the most important distinctions in choosing a saw blade – and it is as important as choosing the wood cutting blade manufacturer you’ll be working with.

If you are going for wholesale wood cutting blade suppliers, you’ll come across different types of blades. The ones that you will be able to choose from are:

Rip-Cut Blades

As we mentioned above, a ripped cut is a type of cut where it’ll be parallel to the workpiece’s grain. This way, the blade wouldn’t have to work with extra effort in making the cut.

If you’re going to use miter saws and other of the sort, DO NOT PURCHASE rip-cut blades. You shall only use rip-cut blades are only for radial arm saws and table saws.

Crosscut Blades

If you ask your wood cutting blade supplier what the most popular type of saw blade is, they’ll tell you that it’s crosscut blades.

Designed to have teeth that are sharp and chiseled, you can expect better, higher-quality, and faster results when you choose crosscut blades.

Unlike rip-cut blades, you can use crosscut blades on miter saws – in fact, it’s the only saw blade that’s seen to be the most compatible.

General Purpose Blades

After crosscut blades, the next type of blade you would want your to wrap your head around on would be general-purpose blades.

With general-purpose blades, all its teeth are of the same size and shape. It’s the type of blade that is always interchanged with combination blades because of its features.

Combination Blades

Combination blades are the blades you want if you want your results to revolve around cross and rip-cutting simultaneously.

The reason why most wood cutting blade manufacturers prefer combination blades is because of the multifunctional features that it has.

Akin to rip-cut blade, you’ll only be able to use them with table saws and radial arm saws.

What You’ll Cut

The next thing you want to consider before asking the wood cutting blade manufacturer you’ll be working with is the material you’ll cut.

Wood, in itself, is soft, but wood cutting blade manufacturers up the game. They do by providing specific types of blades to different clients depending on their specific need.

For instance, some wholesale wood cutting suppliers would market saw blade A as the perfect saw blade for softwood, plywood, or laminate. Saw blade B, on the other hand, is the saw blade that you want if you’re going to work on maple, hardwood, and thick-sized wood.

While this is the case, most wood cutting blades that manufacturers produce are perfect for whatever type of wood it is.

The only real precaution in this is that you must refrain from and avoid using wood cutting blades for metals, steels, and concretes because they’ll break and deteriorate faster and easier.

Tooth-Count

Last but not the least is the tooth-count of the wood cutting blade.

In case your wood cutting blade isn’t telling you about it, most blades are categorized by their tooth-count.

To help you understand it, here are a few pointers you can remember about it:

- Rip-cut blade have the fewest teeth, which you can use if you want to cut fast

- All the other three are unpredictable – so you would need to ask your wood cutting blade manufacturers about it.

- The fewer teeth, the faster the cut, but it’ll leave rough and unfinished edges – the more teeth, the smoother the cut, but it’s a bit slower.

The best thing to do to ensure that you’ll be purchasing the correct material is to ask the wood cutting blade supplier you’ll be working with.

They will, oftentimes, direct you to the most appropriate and the best option. Of course, you also have to consider the fact that them, being wholesale wood cutting blade manufacturing companies, are entertaining multiple clients like you.

Which Wood Cutting Saw Blade Makes the Smoothest Cut?

Like what most wood cutting blade manufacturers will tell you, the best cuts can be produced by none other than crosscut blades.

Having teeth that spans from the usual 60 to 80 counts, you can expect it to help you produce the best, the smoothest, and the most flawless cuts.

So, if you’re after smoothness and quality, don’t go around asking your wood cutting blade manufacturer about it. Ask them about which crosscut blades are the best in their arsenal.

How Do You Sharpen Wood Cutting Blades?

Most wood cutting blade manufacturers wouldn’t really tell you that you can sharpen saw blades.

This is for the very reason that they want you to purchase every time it gets dull.

Needless to say, though, it is quite of the expectation that re-sharpened blades would not be as effective as how it was when it was still new.

So, that may be what wood cutting blade suppliers have in mind, too.

To free you from wonder, sharpening wood cutting blades is actually easy:

- Remove or dismount the blade from the saw

- Secure the blade by using a vice gripor any other technique so that it faces upwards

- The next thing you want to do is to make and create marks on the top-side of the blade. This is imperative as this’ll be the sign that you have covered the entire blade.

- Pass the file in four (4) to six (6) strokes up and down.

- Next is you want to turn the blade so that you’ll be working on the other side – do whatever you’ve done in step #4.

- Lastly, you want to file the tips so that they’re finished smoother and better. You would want to go on and file both sides of the tips so that they’re all better, more effective, and more efficient.

That’s the hidden secret wood cutting blade manufacturers wouldn’t easily share with you! But, for safety and precautionary purposes, again, it’s never a guarantee that re-sharpened wood cutting blades will be as effective as how they were before.

There could be lapses on them that you never expected. A good practice is to ask your wood cutting blade supplier if sharpening their saw blade is okay, but most of the time, they’ll tell you that you can if you ask.

Can I Use a TCT Blade as a Wood Cutting Blade?

Akin to the sharpening, many wood cutting blade manufacturers wouldn’t recommend this as well. Why? – Because of the simple reason that TCT saw blades are specifically used in the cutting of metals, steels, as well as other ferrous and non-ferrous metals.

While it’s never “forbidden” to use TCT blades for wood, it’s not the most recommended and the most practical to do.

Can You Use Circular Saw Blades for Wood Cutting?

Yes! In fact, it’s what most wood cutting blade manufacturers recommend.

Because of their versatility, circular saw blades would be the best type of blade you can use for woodwork.

You’ll find this as a fact from most wood cutting blade manufacturers and suppliers from all across the globe.

Can You Use a Sawzall as a Wood Cutting Blade?

While your local wood cutting blade supplier will tell you it’s not possible, you actually can!

In fact, many Chinese wood cutting blade wholesale manufacturers are already on the move in producing higher-quality Sawzall wood cutting blades for the purpose of cutting through wood.

There are limitless options in what you can use for your woodworking – you can even consider using custom wood cutting blades, too!

Can You Purchase Custom Wood Cutting Blade Manufacturer?

With the versatility and diversification of businesses nowadays, you will find it hard to find a wood cutting blade manufacturer that can help you with custom blades.

But if you choose to work with us here at Tenyu Tools Co., Ltd., you will never be disappointed. For more than a decade, we’ve been helping out clients like in producing custom wood cutting blades they need for their business.

Whether they need custom circular wood cutting blades, or any other type of saw blades, we’re ready and prepared to help them.

Wood Cutting Blade Price List

Knowing the price of a particular item from a wood cutting blade manufacturer’s list is difficult. This is why for you to know what the exact price is, the best thing to do is to ask them.

More often than not, manufacturers of wood cutting blades wouldn’t just display their rates and prices scattered. This is because they’re opening their doors on you making deals with them.

For instance, we here at Tenyu Tools Co., Ltd. can strike up a deal to help you with the wood cutting blade manufacturing company you have back in the West.

If you’re purchasing 2,000 units of wood cutting blades wholesale monthly, we can work up a deal so you can save more money long-term.

With Tenyu Tools Co., Ltd. as your wholesale wood cutting blade manufacturer, you will never have any problems on the quality, the supply, the volume, and the overall production capacity that we have.

What Wood Cutting Blades Do We Offer Here in Tenyu Tools Co., Ltd?

In case you’re wondering, we have a complete lineup of various wood cutting blades that you can purchase wholesale.

We have 4-inch 40-teth circular saw blades which are perfect for the wood cutting blade supplying business you have, we have PCD or polycrystalline diamond fiber cement cutters, 10-inch 80-teeth ATB, and many more!

You can find all the other wood cutting blade products and items that we have on our website!