Carbide Blade

- Why Should you Choose Tenyu to be your Supplier and Manufacturer?

- You can receive sharper and more accurate carbide blades.

- You’ll never have to think about purchasing these tools again because they offer long life expectancy.

- You can expect to receive extremely tough blades for your power tools.

- Tenyu Tools’ carbide blade is resistant to extreme temperature and thermal damage.

Tenyu: Your Leading Carbide Blade Manufacturer

Why Choose Tenyu Tools’ Carbide Blades?

Since 2000, Tenyu Tools Co., Ltd. has been the top brand in carbide blade manufacturing. We have been providing all our clients the quality of custom carbide blades they deserve.

Because of our Research & Development (R&D) team, we can specify and accurately produce the custom carbide blades that you need!

You can also ask us for a free sample if you wish to!

You Can Trust Us

- You can approach us if you have damaged or broken screw extractors; we do repairs and replacements, too!

- You can trust our processes as we use machines we manufactured ourselves!

- You can freely visit our manufacturing plant that is over 5,000 square meters!

- You’ll visibly see the factory next to our warehouse!

You can always bank and count on Tenyu Tools Co., Ltd. if you are in need of carbide blades!

Whether you need pre-made carbide blades, or if you want custom carbide blades – you can trust us!

Upon visitation, you’ll be able to see the effectiveness and efficiency of our R&D team!

Send inquiry now! we can reply in 24hours!

- Manufacturing Machine for Carbide Blade

Carbide Blade Manufacturers – The Extraordinary FAQ Guide

Looking for carbide blade manufacturers is one of the toughest things to do. If you don’t have any ideas on the history of a supplier or a manufacturer, you’re clueless about their quality.

So how do you look for the best manufacturers of carbide blades? This guide is for you!

In this FAQ Guide, we’ll help you understand carbide blades better, as well as how you can choose the best manufacturers for it.

What are Carbide Blades?

Carbide blades, also known as carbide tips, are additions to a body of steel.

You usually attach them at the “tip” or at the edge of blades to be sharp, accurate, and efficient.

Understanding the Composition of Carbide

You can think of carbide as an element, or rather – a compound.

Its basic composition includes carbon (C) and a type of alloy or any metallic steel.

One good example is tungsten carbide, the metal part is tungsten, partnered up with carbide.

What is a Carbide Blade Used For?

Carbide is known for its sharpness and relative toughness.

Therefore, you can choose to use it for cutting, slicing, and other forms of fabrication.

You can find it almost all the time with craftsmen, woodworkers, diamond workers, etc.

But, you can also find use for it in the following industries:

- Surgical Tools

- Milling and Turning Products

- Jewelry

What are Carbide Blade Tips?

Carbide tips or carbide blade tips are the same. They’re just different terms.

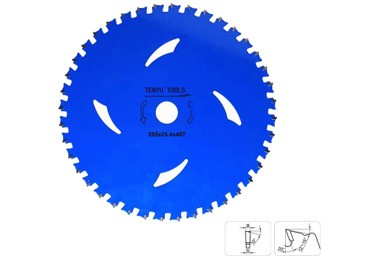

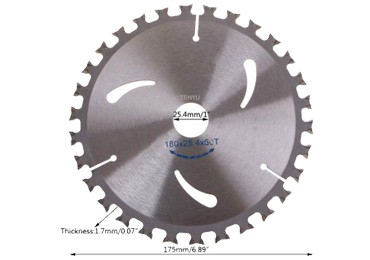

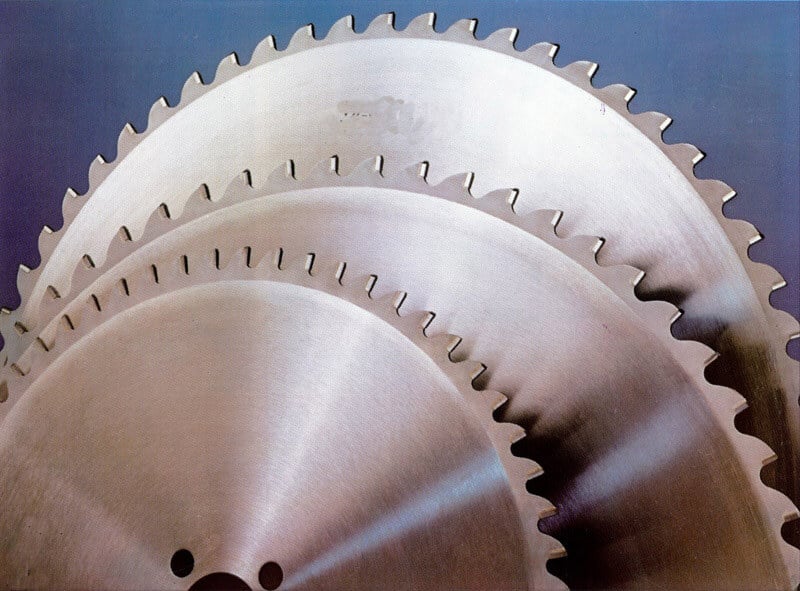

What are Carbide Blade Circular Saws?

They’re circular saws that you can use to cut wood, concrete, metal, diamonds, etc.

Depending on your project, you can ask to build or produce a specific carbide saw blade.

How are Carbide Inserts Made and Manufactured?

Typical carbide inserts are comprised of 20% metal matrix, and 80% carbide.

- The usual carbide inserts start as powder

- Then, a container will be filled with a mixture of all the ingredients necessary for the process

- The mill is also filled with water and ethanol, a solution popular for manufacturing carbide tips

- Once done, the result will be dried for up to 55 hours, depending on the consistency – it should become powder

- After being finalized and inspected, the powder is transported to the pressing machines

- The platen or the cavity will be filled with the powder made

- It’s then sent to an oven where the made insert will be heated to harden

- Lastly, it’s going to be left for more than 10 hours for everything to fuse

Depending on the insert quality, it’s going to come back and forth to the laboratory and the rebuilding to be checked and inspected.

Carbide vs. Tungsten Carbide

A lot of people misuse the word “carbide” for “tungsten carbide.” They think that it’s just the same.

How to Choose the Right Carbide Blade Manufacturer

You can find many carbide blade tip manufacturers and suppliers in the market.

However, some of them have distinctive prices and rates, offering the same quality.

In this case, you need to choose the correct manufacturer of carbide tips. Here are some of the best strategies you can take advantage of.

Checking Reviews

Whatever type of product you’re looking to purchase, the best thing to do initially is to check the reviews of the company or the manufacturer you’re eyeing on.

This can tell you a lot about the quality of their products, their service, response time, etc.

Do They Offer Free Samples?

Another thing you want to check on would be their samples.

Does the manufacturer you’re eyeing on offer free samples? Or do they require you a minimum order for you to get an item?

Checking if a manufacturer offers a free sample is imperative because you’ll be able to get a firsthand look at what you’re about to get.

Customization of Orders

There are manufacturers that just stick to the products they have. They’re afraid to customize or to specify an order.

There are manufacturers, though, that accept customization of orders. These manufacturers usually have their own consultants and research & development (R&D) teams.

You would want to choose them because you don’t have to worry about adjusting what you already have from the carbide tips and blades you’ll be getting.

Their Rates

Lastly, it’s typical to think that low rates are too good to be true – because they are!

You may be able to find suppliers that offer unbelievable low rates, but think about it. Would they have good business if they didn’t have enough capital?

Rates are crucial – rates that are unbelievably low almost always guarantee insufficient quality. Higher than the usual rates, on the other hand, might not satisfy you.

Do your research on how much the prices and rates are regularly. You might be surprised at how far you’re imagining them to be!

Those are just some of the few tips you can use to find the best and the right manufacturer for your carbide blades.

If you have other strategies, good for you! These are only general guidelines you can utilize, and it has proven a lot of businesses.

Usual Rates of Carbide Blades and Tips

Purchasing carbide blades and tips usually come in a package.

For instance, if manufacturer A offers a box of 100 pieces for $500, then it’s $5 each. The rates of these carbide tips and blades largely differ because there are many different types and kinds.

But, carbide blade and tips can have rates between $1 and $100, depending on the size, make, type, and use.

Can Carbide Blades be Used for Cutting Steel?

Yes, you can use carbide blades to cut steel.

In fact, you can use most types of carbide blades in slicing and cutting through both non-ferrous and ferrous metal.

However, you need to be aware of the fact that in cutting metal using carbide blades, the limit is usually just about 3/8 inches thick.

Going thicker than that might require additions to the steel base or the carbide tip itself.

Saw Blade Sharpening Near Me

One of the most common misconception that people have when it comes to carbide blades is that it can’t be sharpened.

When in fact, it can actually be sharpened! The ideal amount of sharpening sits between three (3) to four (4) times; going over can damage the teeth and kerfs, requiring you to replace it.

You can try searching for the nearest saw blade sharpening services from where you are located.

There are businesses and companies scattered out in the market; you just have to make sure to choose the company that can really do an excellent job.

Applications of Carbide Blades

Many businesses find carbide saw blade manufacturers as they understand the benefits it has.

The following are the types of industries and businesses that usually look for carbide blades:

- Forestry Industry

- Woodworking Industry

- Furniture Making

- Metalworking Industry

- Welding and Fabrication Industry

- Construction and Structural Industry

- Coal and Mining Industry

- And Many More!

You’re not just limited to these industries and sectors.

Now that you know the uses of carbide tips and blades, it’ll be easier for you to figure out if carbide tips and blade are what you need!

Carbide Blades for Woodworking

Woodworking isn’t just the activity of cutting regular naturally thin wood; you also need to consider hardwood, cedar, maple, and the like.

While these types of wood are hard, you can trust a lot of carbide tip manufacturers to help you. You can ask them to specify and customize a particular carbide blade so it fits what you need it for.

There are certain types of carbide tips and blades – take tungsten, for example – that can cut through a wide variety of materials.

Carbide Tip Replacement: Can it be Done?

Akin to how other additives and tools are, carbide blades and tips wear out.

If you use them more often, they’ll wear out faster; it’s not like they stay like what they are forever.

When the time comes that you either need to repair or replace them, you can have a carbide tip replacement.

Whether you’re replacing a blade or a tip, it is easy; you just have to follow these steps:

- Remove the old carbide material by heating them, you can use a torch

- Push out the carbide material off of it – it doesn’t fall off on its own

- Prepare the new carbide material (blade or tip) and position it on the steel body

- Utilize a braze flux and start by applying it to where you need the new carbide material

- Place the new carbide material with the alloyed braze side against the flux

- Heat it so that the two materials integrate together. Usually, a temperature of 1,500 degrees Fahrenheit is too much, keep it within the ranges of 1,200 to 1,350 for the steel.

Can Carbide Tip Saw Blades be Repaired?

Manufacturers of carbide blades and carbide tips usually also offer repair or replacement. Yes, you can repair carbide blades if you think it’s not yet the best time to replace them.

You can choose to repair circular saw blades, carbide inserts, etc. You can have them re-sharpened, if they need sharpening, or repaired if they’re damaged.

Repair of carbide blades would be depending on the skill and experience of the company.

What are Cemented Carbides?

A cemented carbide is an extra hard material you can use as a cutting tool – just like carbide.

Usually, it’s just a regular tungsten carbide with a different finish.

How are Cemented Carbide Blades Manufactured?

You can create or make cemented carbide by fusing heat-resistant, hard carbides with metal. Usually, cemented carbides are manufactured by following this general structure:

- Preparation of powder (breaking of the materials into their powder forms)

- Pressing and forming of the carbide

- Sintering or compressing (volume reduction, can go as much as 50%)

- Surface treatment (grinding, polishing, edge preparation, sand blasting, erosion, etc.)

- Quality control

Where Can You Find Custom Carbide Blade Manufacturers?

It’s not that difficult to find carbide blade manufacturers, especially if you know where to look.

China is a country home to a lot of manufacturers, and we’re globally recognized. Because of this, a lot of businesses and companies took this opportunity to develop and enhance to cater to more businesses worldwide.

The Best Manufacturer of Carbide Blades in China

Here in China, Tenyu Tools Co., Ltd. is the top and the most reliable manufacturer of carbide blades and tips.

You’ll never have a problem if you choose to work with us here at Tenyu Tools. Since 2000, we’ve given all our clients the particular carbide blades that they needed.

Whether they’re looking for carbide tips and inserts, circular carbide saw blades, drill bits, grinding wheels, etc., we will be able to deliver!

You can also get carbide tools from us! Just say the word and we’ll get it working for you!

Why Tenyu Tools is the Best in Offering Carbide Blades

- You can trust us to provide high quality carbide blades

- You can get our products wherever you are in the world

- You can get all your orders within 2 to 6 weeks

- Your requests will be accommodated fairly through the help of our Research & Development (R&D) team!

- You can ask us for a free sample of the carbide blades you need!

Tenyu Tools Co., Ltd. is one of China’s top and most sought after carbide blade manufacturers. All your needs and requirements in terms of carbide material – you can trust us!

You can expect us to produce carbide circular saw blades, carbide tips and inserts, carbide drill bits, and many more!

Tenyu Tools’ Carbide Blades

Being the best manufacturer of carbide blades, you will never have any problems in choosing us.

You can purchase carbide blades to cut through a wide range of materials, such as:

- Wood

- Paper

- Concrete and Masonry

- Metals and Steels

- Glass

- And Many More

You have the chance to get the best and the highest quality of carbide-based tools if you choose us! You can get all the power tool accessories you require in the cheapest and most reasonable rates!

Applications of Our Carbide Blades

You can use the carbide blades that we offer here at Tenyu Tools for a wide range of applications!

- Woodworking and Furniture Making

- Steel or Metalworking

- Shipbuilding & Shipyard Industry

- Jewelry Industry

- Paper and Pulp Industry

- Forestry Industry

- And Many More!

What are Other Products We Offer?

Aside from general carbide blades and tips, you can also trust us if you need:

- Drill Bits and Custom Drill Bits

- Circular Saw Blades

- Nibbler Cutters

- Grinding Wheels

- Screw Extractors

- Etc.!

Reach out to us and experience the care of the best carbide blade manufacturer in the industry. Contact us and have us create the exact carbide tips you need!

Custom Made Carbide Blades and Tools

Apart from our expertise in handling carbide-induced materials, Tenyu Tools is also the company you can trust if you’re looking for custom carbide blades.

We have our dedicated Research & Development (R&D) team to craft the specific type of tool you need!

- You can get high quality products in just a short time period

- Whether you’re in Eastern or Northern Europe, North America, Asia, and Africa, you can get our products!

- You can receive a large volume of the tools that you need on a daily basis!

- All our tools are assessed and inspected before packaging

Tungsten Carbide Blade Manufacturers

In case you didn’t know, there’s a myriad of tungsten carbide blade manufacturers in the market today.

As a matter of fact, you are not limited to choosing a manufacturer from the United States or even in other countries in Europe.

We here at Tenyu Tools are known to provide some of the industry’s top and most-wanted tungsten carbide blades! Our products reach the far ends of the globe as we produce tungsten carbide blades for businesses and companies in different regions of the world!

Types of Carbide Saw Blades

Contrary to popular belief, there is but one type of carbide saw blade that you can purchase in the industry.

In fact, you’ll be able to find multiple types and kinds of carbide saw blades and among the most common of them include:

- Carbide Tipped Standard Saw Blades

- Cermet Tipped Saw Blades

- Friction and Hot Saw Blades

- Carbide Tipped Thin Kerf Saw Blades

- Segmental Saw Blades

- Solid High Speed Steel (HSS) Saw Blades

NOTE: These are not all the types of carbide saw blades there is. These are just the most common and the most popular because they’re the most predominantly used in the market.

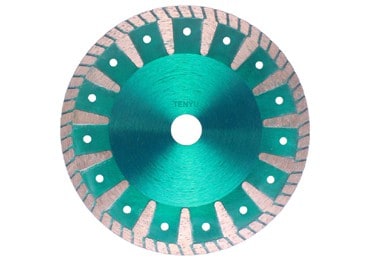

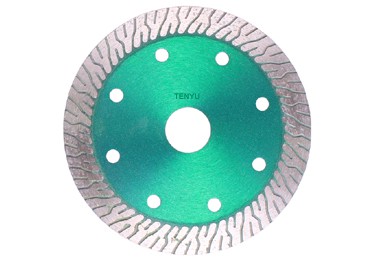

Differences Between Carbide Blade and Diamond Blade

A lot of you might have thought that diamond blades and carbide blades are the same. When, in fact, they are far different from one another.

NOTE: What we’re talking about here would be the tip or the added coating on the teeth of your saw blades.

In order for you to understand and to comprehend it a little better, here’s a table of their differences:

| Carbide Blades | Diamond Blades |

| Best used for cutting wood, plastics, as well as ferrous and non-ferrous metals. | Ideally used for the cutting or the processing of concrete, tiles, asphalt, and other masonry. |

| Also known as “tungsten carbide blades.” | Also known as “continuous rim blades.” |

| Has about 60 to 100 teeth, depending on the application. | Can contain up to 40 teeth. |

You might look at and consider them to be the same, but, they’re actually not. They’re different in terms of application, how they’re used, how you can clean, maintain, and care for them, as well as how they react when they’re used abruptly.

There are far more differences between carbide blades and diamond blades, these are just part of the most common and most noticeable.

What Can You Cut With Carbide Blades?

Carbide blade manufacturers usually market their products as an all-around type of cutting tool.

In fact, here are some of the different materials that you can use carbide blades for.

Wood

Wood is actually the primary material that these carbide blades can cut. They’ve been engineered and designed to cut wood and other similar materials with precision and accuracy.

Steel and Metal

Not all carbide blades are designed to cut metal. However, there are certain specialized carbide blade manufacturers that produce steel and metal-cutting carbide blades, like us here at Tenyu Tools.

Plastics and PVCs

Plastics or PVCs follow wood in the list of the materials and things that carbide blades can cut. Since they’re not as hard as metal, it’s safe to consider the vast majority of carbide blades to be used for cutting PVCs and plastics.

Can Carbide Blades Cut Masonry?

It’s not a common feat for a carbide blade to be used for cutting masonry like stones, rocks, asphalt, cement, tiles, and others of the same kind.

Just like metal and steel-cutting carbide blades, there are specialized tools that would help and allow you to cut masonry. But, if your application requires you to cut or slice through masonry, then purchase a diamond blade instead.

What to Look For in a Carbide Blade?

It’s difficult to tell a good carbide blade from a bad carbide blade if you are not well versed when it comes to the grade of the steel used. Unless you’re a steel expert, you’ll find it almost impossible to tell apart.

So, here are a few of the most important tips that you can use so that the carbide blade you will be purchasing are going to be of a good quality.

Physical Toughness

In the industry, there’s nothing more important than the physical toughness and strength of a carbide blade. This will determine the efficiency and effectiveness of the blade regardless of what application you will have for it.

You can check the toughness and durability of the carbide blade by:

- Asking for an official sample

- Testing the blade

- Contacting previous customers that purchased it

Longevity

The longevity of the carbide blade will determine if you’ll actually be able to use it again in the future. Most carbide blades would have the same lifespan, and it will also actually depend on how you use it.

So, ask your manufacturer of the maintenance of it, as well as what the best ways are to use it.

Application and Use

Lastly, you need to consider the application or the usage of it. It’s not right to purchase a carbide blade if you’re going to use it for masonry without knowing if it’s eligible to be used for masonry.

Consider what you’ll be using it for, as well as the future uses you may have for it.

These are the top things that you would want to consider when choosing a carbide blade for your business.

Features and Benefits of Tenyu Tools’ Carbide Blades

Tenyu Tools’ carbide blades are so effective and efficient that they’ve immediately been picked up by a lot of business sectors and industries worldwide.

Some of the most notable features of our carbide blades include:

- High resistance to wear and tear

- Corrosion-resistant

- Has excellent-quality friction control and distribution

- They’re easy to use

You can consider Tenyu Tools as your main carbide blade manufacturer, wherever you are! Send us an email or an inquiry through our website – get a free quotation, too!

Receive high quality carbide blades and tools for a competitive rate that you can’t find elsewhere!