Many people have now shifted their focus on DIY projects rather than getting professional workers for woodworks, furniture-making, and other such tasks. Not only does woodworking all by yourself save you the extra costs of using professional services, but it also gives you good physical exercise.

However, buying the right tools and equipment is essential for these jobs to be completed efficiently. As a result, the demand and need for high-quality blades have increased, and people are now focused on finding the right sellers, retailers, and wholesalers who can provide them with the right product.

As a wholesaler or importer, it is vital to keep stocked-up with the perfect, highest quality blades. But how does one identify the right blades to keep in stock? This article will help you decide how to select the best kind of wood circular saw blades to keep in your wholesale stocks.

As a wholesaler or importer, it is vital to keep stocked-up with the perfect, highest quality blades. But how does one identify the right blades to keep in stock? This article will help you decide how to select the best kind of wood circular saw blades to keep in your wholesale stocks.

What is a Wood Circular Saw Blade?

You need to understand the core functionality, propose, and mechanism of a saw blade. These blades are multi-purpose and have several dimensions to them. While looking up wood circular saw blades, remember that they can be used for multiple materials and purposes at once.

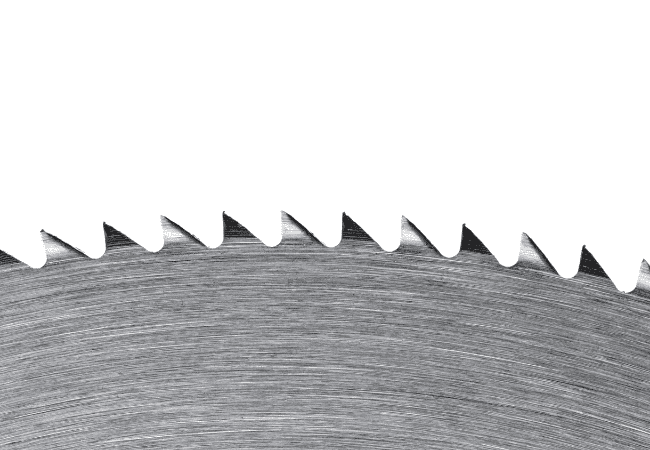

Wood-working requires a power saw that runs on an electric motor. The circular saw is usually a piece of hand-held equipment that you use for cutting wood as well as other materials such as plywood and even metals. The blades, or the teethed discs, work in a circular, spinning motion that allows the machine to cut through the material. There are several different kinds of blades available in the market, varying in terms of their sizes, teeth type, construction material, and so on.

If you are looking for saw blades to add in your wholesale stock, here are some important features you can consider.

Features to consider when buying a blade

The following features are all related to the blades; therefore, giving importance to these features can help you pick the right kind of products to add to your stock.

● Teeth

Generally, the rule is that the more teeth the blades have, the finer, cleaner cuts are made. However, that is not the only thing to consider. Another important thing to consider about the teeth of the blades is to identify the type. We have discussed the different types of teeth later on.

● Thickness

The thickness of the blade is also referred to as the kerf. A thicker blade will mean better, sturdier construction and, therefore, a longer-lasting life. Thick blades also have more room for sharpening them up if they become bland.

However, due to heavier mass, more thickness means slower functionality. Therefore, many people prefer going for thinner blades since they work faster and give more precision. It’s good to have both kinds in your product portfolio as both the blades have separate applications, uses, and benefits.

● Gullet

The gullet is often considered to be a technical term that not many people are aware of. However, the importance that this feature has in selecting and finding the right blades is immense.

The gullet is basically the space between two teeth of the blade. This space has a very technical function to play; it accommodates chippings, dust, dirt, and any other waste from all the wood cutting. The larger space is, the more deposit it can hold. This way, dust and wood chips do not get in the way of your blade cutting the material.

Different kinds of blades have deeper depths and sizes of gullets. Normally, ripping blades have a very deep gullet, compared to cross-cutting blades that have smaller gullets.

● Expansion slot

Since there is a significant amount of friction between the blade and the material being cut, a lot of heat is produced. To prevent the blade from deforming due to extreme heat, an expansion slot is added to the blade’s design through laser cutting.

● Material to cut

For woodcutting, all saw blades are not appropriate. As a wholesaler, you will have customers asking you for blades that are particularly suitable for certain materials. Therefore, if you want to stock up on wood circular saw blades make sure to check the compatibility of the blades you are buying.

Different types of blade

Woodcutting is not as easy as it sounds since there are a lot of technicalities to take care of. Keep in mind that each kind of blade cuts different types of woods, and makes cuts differently as well.

Let’s see how the differences matter:

● Ripping blades

These are primarily used for cutting the wood in a parallel direction to the wood grains. These kinds of blades do not make smooth cuts and also cut faster. Therefore, they are used for initial cutting.

● Crosscutting

These blades are known for creating smoother cuts in a cross-direction of the wood grain. They have fewer teeth.

● Plywood blade

As the name itself suggests, these blades are used primarily for cutting plywood. They are known for their smooth, fine cutting quality due to the extra sharp teeth that are also greater in number.

● General-purpose blades

Also known as all-purpose blades or combo-blades, these are perfect for cutting all kinds of woods in all various directions. This means that the blade can cut cross the wood grain, or parallel to it. These are the most commonly used ones and therefore have a higher demand since they are appropriate for all applications.

● Finishing blades

Very obvious from the name, finishing blades are able to create fine, smooth cuts and are used at the very final stages of the wood-cutting project. They have a larger number of teeth and are used for precise and fine cuts. For woodwork that requires wood carving and cuts on the exterior, these kinds of blades are incredible.

● Kerf

As we discussed earlier, the kerf is basically the thickness of the blade, or the cut you are making. So, thin kerf blades are specialized units made particularly for fine and thin cuts. These blades are not appropriate for thick or tough wood since they can easily bend due to the extreme thinness. So, for use with a softer wood, thin kerf blades are ideal.

● Plastic blades

While there are not any particular blades made for plastic cutting, it is true that you can use wood-cutting blades for cutting plastics as well. The main key here is finding a blade with more teeth and good build quality, so it does not flex easily on hard plastics.

● Masonry blades

It is important to know what other out-of-the-box options you should stock up on. Your knowledge about the variety of products available will help you select the perfect products for your business.

Therefore, masonry blades are not for woodcutting but are for fiberglass. These kinds have no blades at all. Their mechanism depends upon wearing away the material and slicing through it rather than cutting through like other wood-blades.

Types of teeth

Now that you have learned about the most important features to consider and the various kinds of blades, let’s take a look at how the blades’ teeth differ.

● Flat top

For working with hard, tough, and thick wood, flat top teeth work the best. These are used to make rough cuts, as they rip the wood along with the grains as well. This is also the most durable kind of blade teeth.

● Alternate top bevel

The complete name for these blades is Alternate Top Bevel with Raker, also referred to as the ATB/R teeth. These are ideal for crosscutting and smooth cuts. However, the main feature of these is that they have alternating shapes and patterns of the teeth, which means that each tooth is right and left-handed alternatively.

● Triple chip grind

Referred to as the TCG, or California Chip grind, these teeth basically have a unique trapezoid-like shape, allowing the cutting force to be evenly distributed throughout the blade. Due to this design, these blades have lower wear and tear and can also create smooth cuts.

What are coated wood circular saw blades?

Saw blades are bound to get wear and tear and gradually become dysfunctional. However, delaying this wearing-off process as much as you can is important for consumers. To do this, there is a huge range of products available that actually have a surface with a protective coating over them that protects them from corrosion and rust.

However, there is one drawback to coated saw blades; they cost more than uncoated ones. It’s also interesting that some blades only have teeth that have a coating on them, but the rest of the blade remains uncoated; these might be somewhere in the mid-range of the price spectrum.

How to select the right seller

As an importer or wholesaler, choosing the appropriate, most suitable seller for your supplies is essential for success. There are certain ways you can use to ensure that the seller you are buying your supplies from is trustworthy and is worth your time and effort. It has to be a sustainable relationship, so you don’t go jumping from supplier to supplier.

Here are some considerations you can make:

● Customer support

You will be the customer to the seller. You can inquire about the protocols and policies they have in place to treat their customers. Good customer support can perhaps provide information and details about the product honestly and generously. In case of damages during the delivery of products, there has to be some policy or guarantee in place to save you from extra costs.

● Flexible pricing

Since you will be buying in bulk, the pricing of the products should be flexible. As a wholesaler, you cannot buy expensive stocks. Concessions, deals, and discounted bundles are ways your supplier/seller can help you with your costs and establish a good buyer-supplier relationship.

● Ease of contact

Since you will be in constant contact with your supplier, requiring information about the products or perhaps getting updates on the next scheduled delivery should be easy, so contacting them should be convenient. A seller who has up-to-date networking gadgets, such as free messaging applications and smart devices, is more suited for this reason.

Conclusion

Buying wood circular saw blades in bulk from a reliable seller is really important. You must know all the varieties of blades available and select the products you want to buy accordingly. Since woodworking in DIY-projects is becoming common day by day, the demand for hardware tools such as these saw blades will not be slowing down anytime soon. Therefore, having a diverse range of multiple kinds of blades in your product portfolio is essential.

Ich entschuldige mich aufrichtig für diesen Kommentar! Aber ich teste einige Software zum Ruhm unseres Landes und ihr positives Ergebnis wird dazu beitragen, die Beziehungen Deutschlands im globalen Internet zu stärken. Ich möchte mich noch einmal aufrichtig entschuldigen und liebe Grüße 🙂

Liebe Grüße! Deine Nutzung von Musik-Playlists in Verbindung mit bestimmten Themen ist eine interessante Idee. Wie wählst du die Musik aus, um die Atmosphäre deiner Beiträge zu beeinflussen, und gibt es bestimmte Genres oder Künstler, die du bevorzugst?