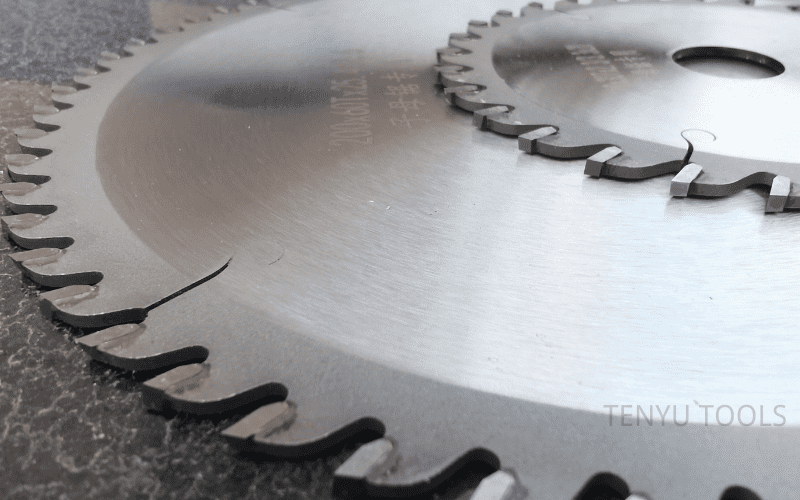

Tenyu Tool ™ circular saw blades are produced with a unique Cermet II tip that permits the blades to reduce at faster feed prices as well as remain sharp much longer. With our Cermet II tipped blades you will certainly be purchasing a circular saw blade that provides a much better side than typical carbide-tipped blades, remains sharper much longer, and also is extra immune to tip crack. The innovative modern technology made use of in Cermet II suggestions makes them much more warmth immune than carbide, enabling you to reduce at faster feed prices without hurting the circular saw blade or melting your wood. When it does come time to sharpen, they can be ground much like common carbide blades, so no unique development is required.

Click to obtain a far better check out exactly how we make the Tenyu Tool ™ circular saw blades.

Each Tenyu Tool ™ circular saw blade is customized to order by Carbide Processors. No matter if you’re a lumber mill, a panel handling component, furnishings and also plant store, or a major residence enthusiast – you just will not locate a better-performing circular saw blade anywhere.

Reviews from Tenyu Tool ™ type circular saw blade individuals:

” We’re exceptionally pleased with the teeth on our brand-new 6 tooth blades. We punctured numerous hairs of barbed cable installed in a log and also, while the teeth experienced a couple of chips, they’re still cutting. Thanks for your workmanship, comprehensive understanding, and also the pleasant solution. We’ll be back.”

Secret Sully, Importer, Berkeley Springs, WV.

” I place the ceramic suggestion blade on initial as well as did a number of holes as well as crosscuts. The cuts were glue-ready. There was no demand to sand or prepare the surface areas in any way. You could not sand coating a cut to be any type of smoother than the cuts made by the ceramic pointer blade. When you desire to maintain making cuts simply to reveal pals just how rather the blade cuts, it’s quite unfortunate. I anticipate utilizing it in the future. I do not recognize exactly how you men did it, however, I figured your item would certainly be tough to show versus the modern technology of the Forrest Woodworker II blade. The ceramic ideas you place on offered such exact cuts. I value having actually been offered the possibility to utilize your item as well as would certainly suggest it to any individual.”

Burry T. Wholesale, Huntsville, TX

” I should claim I was really cynical concerning the efficiency of your item. That is no more the situation as well as I placed the blade via its rates on 4 various jobs with 5 types of timber (wood). IMHO, if you place the pointers on excellent spaces, maintain the rate affordably, and also most significantly, give great client assistance, you will certainly achieve success. These viewpoints will certainly be shown in my testimonial. You might also obtain a 17 year Forrest blade individual to alter his stripes.:–RRB-.

Daive

Be sure to check out more Tenyu Tool ™ type circular saw blade Reviews

Combination circular saw blades

Compound Miter circular saw blades

Contractor circular saw blades

Crosscut circular saw blades

Double Miter circular saw blades

Gang Rip and Straightline Rip circular saw blades

General Purpose circular saw blades

Glue Line Rip circular saw blades

Heavy Duty circular saw blades

Horizontal Panel circular saw blades

Laminate Veneer circular saw blades

Melamine Veneer circular saw blades

Miter Box circular saw blades

Plastic and Trim circular saw blades

Plywood circular saw blades

Precision Trim circular saw blades

Radial Arm circular saw blades

Safety Rip circular saw blades

Sliding Table circular saw blades

Solid Surface circular saw blades

Super Finish circular saw blades

Thin Kerf circular saw blades

Vertical Panel circular saw blades

Combination type circular saw blades

With our Cermet II tipped Tenyu Tool ™ circular saw blades you will be purchasing a mix circular saw blade that offers a much better side than typical carbide-tipped blades, remains sharper longer and also is much more immune to tip crack.

| Diameter | Teeth | Plate | Kerf | Bore | Grind |

| 8″ | 35 | 0.085″ | 0.131″ | 0.625″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

| 9″ | 40 | 0.085″ | 0.131″ | 0.625″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

| 10″ | 40 | 0.085″ | 0.131″ | 0.625″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

| 10″ | 50 | 0.085″ | 0.125″ | 0.625″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

| 10″ | 40 | 0.085″ | 0.131″ | 0.625″ | Alternate Top Bevel; 10deg Hook |

| 10″ | 40 | 0.060″ | 0.093″ | 0.625″ | Alternate Top Bevel; 10deg Hook |

| 10″ | 40 | 0.085″ | 0.131″ | 0.625″ | Alternate Top Bevel; 10deg Hook |

| 10″ | 55 | 0.080″ | 0.104″ | 0.625″ | Alternate Top Bevel; 10deg Hook |

| 12″ | 45 | 0.095″ | 0.145″ | 1″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

| 14″ | 55 | 0.109″ | 0.161″ | 1″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

| 16″ | 60 | 0.120″ | 0.172″ | 1″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

Compound Miter type circular saw blades

With our Cermet II tipped Tenyu Tool ™ Compound Miter circular saw blades you will certainly be purchasing a circular saw blade that offers a much better side than common Carbide Tipped Blades, remains sharper much longer, as well as is extra immune to tip crack.

| Diameter | teeth | Plate | Kerf | Bore | Grind |

| 8″ | 35 | 0.085″ | 0.131″ | 0.625″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

| 9″ | 40 | 0.085″ | 0.131″ | 0.625″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

| 10″ | 40 | 0.085″ | 0.131″ | 0.625″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

| 10″ | 50 | 0.085″ | 0.125″ | 0.625″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

| 10″ | 40 | 0.085″ | 0.131″ | 0.625″ | Alternate Top Bevel; 10deg Hook |

| 10″ | 40 | 0.060″ | 0.093″ | 0.625″ | Alternate Top Bevel; 10deg Hook |

| 10″ | 40 | 0.085″ | 0.131″ | 0.625″ | Alternate Top Bevel; 10deg Hook |

| 10″ | 55 | 0.080″ | 0.104″ | 0.625″ | Alternate Top Bevel; 10deg Hook |

| 12″ | 45 | 0.095″ | 0.145″ | 1″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

| 14″ | 55 | 0.109″ | 0.161″ | 1″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

| 16″ | 60 | 0.120″ | 0.172″ | 1″ | 4 Tooth and Raker Grind (4ATB, 1 Raker) Planer; 10° Hook |

Contractor type circular saw blades

With our, Cermet II tipped Tenyu Tool ™ Service Provider circular saw blades you will certainly be buying a circular saw blade that provides a far better side than conventional Carbide Tipped Blades, remains sharper much longer and also is extra immune to tip crack.

For Contractor table saws as well as miter saw that are utilized to cut a selection of products.

| Diameter | Teeth | Plate | Kerf | Bore | Grind |

| 10″ | 24 | 0.085″ | 0.131″ | 0.625″ | 2 Tooth and Raker Grind (2ATB, 1 Raker); 22° Hook |

| 12″ | 30 | 0.095″ | 0.145″ | 1″ | 2 Tooth and Raker Grind (2ATB, 1 Raker); 22° Hook |

| 14″ | 36 | 0.109″ | 0.161″ | 1″ | 2 Tooth and Raker Grind (2ATB, 1 Raker); 22° Hook |

| 16″ | 48 | 0.120″ | 0.172″ | 1″ | 2 Tooth and Raker Grind (2ATB, 1 Raker); 22° Hook |

| 20″ | 60 | 0.148″ | 0.204″ | 1″ | 2 Tooth and Raker Grind (2ATB, 1 Raker); 22° Hook |

Crosscut type circular saw blades

With our, Cermet II tipped Tenyu Tool ™ Crosscut circular saw blades you will certainly be buying a circular saw blade that provides a much better side than typical carbide-tipped blades, remains sharper much longer and also is a lot more immune to tip crack. When crosscutting, obtain unbelievably tidy cuts. This is the optimal manufacturing blade for top-notch industrial crosscut applications.

Usage on: Table Saw, Portable Table Saw, Sliding Table Saw, Mitre Saw, Radial Arm Saw. For extremely smooth end crosscutting as well as cutting in all sorts of strong timber and also plywood. Superfinished rotating bevel teeth easily cut wood fibers. Specifically developed Triple Chip Grind generates smooth, real surface areas for gluing. This is the optimal manufacturing blade for premium business crosscut applications. Generally, choose greater tooth matter for smoother cuts.

Double Miter type circular saw blades

Our Cermet II tipped Tenyu Tool ™ double miter circular saw blades provide a superior edge than normal carbide-tipped blades, keep sharper longer, and are more resistant to tip breakage than conventional carbide-tipped blades.

| Diameter | Teeth | Plate | Kerf | Bore | Grind |

| 10″ | 80 | 0.098″ | 0.122″ | 0.625″ | 4 Alternate Top Bevel and 1 Raker / Wood |

| 10″ | 100 | 0.098″ | 0.122″ | 0.625″ | 4 Alternate Top Bevel and 1 Raker / Wood |

| 10″ | 96 | 0.100″ | 0.125″ | 0.625″ | Modified Triple Chip Grind, Wood/Non-Ferrous; -3° Hook |

| 10″ | 80 | 0.098″ | 0.128″ | 0.625″ | Triple Chip Grind/Aluminator, Non-Ferrous |

| 10″ | 100 | 0.100″ | 0.13″ | 0.625″ | Triple Chip Grind/Aluminator, Non-Ferrous |

| 12″ | 80 | 0.110″ | 0.135″ | 0.625″ | 4 Alternate Top Bevel and 1 Raker / Wood |

| 12″ | 80 | 0.110″ | 0.135″ | 1″ | 4 Alternate Top Bevel and 1 Raker / Wood |

| 12″ | 100 | 0.110″ | 0.135″ | 0.625″ | 4 Alternate Top Bevel and 1 Raker / Wood |

| 12″ | 100 | 0.110″ | 0.135″ | 1″ | 4 Alternate Top Bevel and 1 Raker / Wood |

| 12″ | 80 | 0.110″ | 0.122″ | 0.625″ | Triple Chip Grind/Aluminator, Non-Ferrous |

| 12″ | 80 | 0.110″ | 0.122″ | 1″ | Triple Chip Grind/Aluminator, Non-Ferrous |

| 12″ | 100 | 0.110″ | 0.122″ | 0.625″ | Triple Chip Grind/Aluminator, Non-Ferrous |

| 12″ | 100 | 0.110″ | 0.122″ | 1″ | Triple Chip Grind/Aluminator, Non-Ferrous |

| 12″ | 90 | 0.110″ | 0.135″ | 0.625″ | Modified Triple Chip Grind, Wood/Non-Ferrous; -3° Hook |

| 12″ | 108 | 0.110″ | 0.135″ | 0.625″ | Modified Triple Chip Grind, Wood/Non-Ferrous; -3° Hook |

| 12″ | 108 | 0.110″ | 0.135″ | 1″ | Modified Triple Chip Grind, Wood/Non-Ferrous; -3° Hook |

Applied to: Table Saw, Compound Mitre Saw, Sliding Compound Mitre Saw, Radial Arm Saw, and Double Mitre Saw are all types of miter saws. Inwood and non-ferrous applications, it’s used on production type double miter machines like CTD and Pistorius. The Double Mitre blade is ideal for picture frame shops, window and door makers, and other businesses that employ production miter machines. Inwood, the DW produces chip-free miters.

Gang Rip and Straightline Rip type circular saw blades

With our, Cermet II tipped Tenyu Tool ™ Hole circular saw blades you will certainly be purchasing a circular saw blade that provides a far better side than basic Carbide Tipped Blades, remains sharper much longer, as well as is a lot more immune to tip crack.

| Diameter | Teeth | Plate | Kerf | Bore | Grind |

| 10″/250mm | 24 | 0.080″ | 0.125″ | 0.625″ | Triple Chip Grind; 22° Hook |

| 12″/305mm | 24 | 0.080″ | 0.125″ | 1″ | Triple Chip Grind; 22° Hook |

| 250mm | 20 | 0.070″ | 0.11″ | 70mm | Triple Chip Grind; 20° Hook |

| 350mm | 28 | 0.098″ | 0.137″ | 70mm | Triple Chip Grind; 22° Hook |

Usage on: Straight Line Rip, Gang Rip Saw. APPLICATION: Cutting strong completely dry wood.

General Purpose type circular saw blades

With our Cermet II tipped Tenyu Tool ™ basic objective saws you will certainly be purchasing a circular saw blade that offers a much better side than typical carbide-tipped blades, remains sharper much longer and also is a lot more immune to tip crack.

Usage on: Table Saw, Portable Table Saw, Sliding Table Saw, Mitre Saw, Radial Arm Saw, Double Mitre Saw, Vertical Panel Saw. This basic objective timber blade is made to do greater than one work. The boosted benefits of this blade over others are: C-4 wear immune carbide, Great for tearing as well as cross-cutting, Lasts much longer in basically all timber and also timber items, Less costly to the solution (much fewer teeth to develop), Material needs little or no sanding after being reduced, Severs bit board as well as plywood cleaner, 20deg Alternate Top Bevel, Bigger craws that do not congest.

Equivalent to systematic 51821.

Braze tools (CT carbide tipped or TCT Tungsten Carbide Tipped) Have an item of pricey tungsten carbide brazed to a steel shaft. This provides you the extraordinary lengthy wear of carbide (approximately 100 times that of steel), as well as the durability of steel, saw plate, router shaft, and so on. It makes a plainly premium tool at a significantly decreased price.

Carbide brazing is finished with a high silver braze alloy. The braze alloy (silver solder, high silver solder, high-temperature silver solder) has to do with 50% Silver. This makes it pricey however it is truly worth it. Unlike various other add-on techniques, great brazing creates a mechanical as well as a chemical bond in between the carbide and also steel to ensure that the bond is a lot more powerful than either the steel or the carbide. It likewise imitates a suspension on a car and truck because it supports the tough carbide device idea to safeguard it from cracking, damaging, and also excess wear.

Brazing is the signing up of 2 different products via making use of a 3rd product at temperature levels over 800 ° F. (There are various other meanings yet they are all quite near this.).

Glue Line Rip type circular saw blades

With our Cermet II tipped c Glue Line Rip circular saw blades you will certainly be buying a circular saw blade that provides a much better side than basic carbide-tipped blades, remains sharper much longer and also is extra immune to tip crack.

| Diameter | teeth | Plate | Kerf | Bore | Grind |

| 10″/250mm | 24 | 0.080″ | 0.125″ | 0.625″ | Triple Chip Grind; 22° Hook |

| 10″ | 30 | 0.095″ | 0.145″ | 0.625″ | Triple Chip Grind; 22° Hook |

| 10″ | 40 | 0.095″ | 0.145″ | 0.625″ | Triple Chip Grind; 22° Hook |

| 12″/305mm | 24 | 0.080″ | 0.125″ | 1″ | Triple Chip Grind; 22° Hook |

| 12″ | 36 | 0.109″ | 0.161″ | 1″ | Triple Chip Grind; 22° Hook |

| 12″ | 36 | 0.109″ | 0.161″ | 3.125″ | Triple Chip Grind; 22° Hook, With Keyway |

| 12″ | 40 | 0.109″ | 0.161″ | 1″ | Triple Chip Grind; 22° Hook |

| 14″ | 36 | 0.120″ | 0.172″ | 1″ | Triple Chip Grind; 22° Hook |

Usage on: Table Saw, Sliding Table Saw, Straight Line Rip, Gang Rip Saw. For adhesive joint smooth, straight rip cuts in all sorts of strong timbers. Particularly created Triple Chip Grind creates smooth, real surface areas for gluing and also surface job. Extremely suggested for reducing woods. Select reduced tooth matter for power feed applications.

Heavy Duty type circular saw blades

With our Cermet II tipped Tenyu Tool ™ circular saw blades you will certainly be buying a blade that provides a much better side than basic carbide-tipped circular saw blades, remains sharper much longer, as well as is extra resistant to tip crack.

| Diameter | Teeth | Plate | Kerf | Bore | Grind |

| 8″ | 24 | 0.085″ | 0.131″ | 0.625″ | Flat Top Grind; 22° Hook |

| 10″ | 10 | 0.095″ | 0.145″ | 0.625″ | Flat Top Grind; 22° Hook |

| 10″ | 24 | 0.095″ | 0.145″ | 0.625″ | Flat Top Grind; 22° Hook |

| 12″ | 12 | 0.109″ | 0.161″ | 1″ | Flat Top Grind; 22° Hook |

| 12″ | 24 | 0.109″ | 0.161″ | 1″ | Flat Top Grind; 22° Hook |

| 14″ | 24 | 0.120″ | 0.172″ | 1″ | Flat Top Grind; 22° Hook |

| 16″ | 30 | 0.134″ | 0.19″ | 1″ | Flat Top Grind; 22° Hook |

Usage on: Table Saw, Portable Table Saw, Sliding Table Saw, Straight Line Rip, Gang Rip Saw. Sturdy, high-production slit blades for all kinds of strong timber. These blades create an excellent surface as well as are fit for both tough as well as soft timber applications. Generally, choose reduced tooth matter for power feed applications as well as make use of greater tooth trust hand-fed equipment. Exceptional blades for supply break down.

Horizontal Panel type circular saw blades

With our, Cermet II tipped Tenyu Tool ™ Horizontal Panel circular saw blades you will certainly be buying a circular saw blade that offers a far better side than typical carbide-tipped blades, remains sharper much longer and also is much more immune to tip crack.

| Diameter | teeth | Plate | Kerf | Bore | Grind |

| 300mm | 72 | 0.086″ | 0.126″ | 1″ | 12 Hook |

| 300mm | 72 | 0.086″ | 0.126″ | 30mm | 12 Hook, Scheer, Panhans |

| 350mm | 72 | 0.110″ | 0.173″ | 1-1/4″ | 12 Hook, SCMI |

| 350mm | 72 | 0.110″ | 0.173″ | 75mm | 12 Hook, Gibben, Euromac |

| 350mm | 72 | 0.110″ | 0.173″ | 80mm | 12 Hook, Casadei |

| 380mm | 72 | 0.110″ | 0.173″ | 60mm | 12 Hook, Holzma |

| 400mm | 72 | 0.110″ | 0.173″ | 30mm | 12 Hook, Scheer, Schelling |

| 400mm | 72 | 0.110″ | 0.173″ | 75mm | 12 Hook, Gibben, Euromac |

| 420mm | 72 | 0.110″ | 0.173″ | 60mm | 12 Hook, Holzma |

| 450mm | 72 | 0.110″ | 0.173″ | 60mm | 12 Hook |

| 450mm | 72 | 0.110″ | 0.173″ | 80mm | 12 Hook, Holzma, Gabbiani |

| 500mm | 72 | 0.148″ | 0.19″ | 60mm | 12 Hook, Gribben |

Usage on: Holzma, Gabbiani. APPLICATION: Clamp beam of light equipment reducing plastic laminated and also melamine dealt with the board, solitary sheets or in heaps. Suit with conelike work racking up blades. Three-way Chip Chamfered Raker work.

Laminate Veneer type circular saw blades

Usage on: Table Saw, Portable Table Saw, Sliding Table Saw, Radial Arm Saw. Chip-free cuts in high-pressure laminates and also fragile wood veneers without a racking up saw (TABLE SAWS ONLY). the one-of-a-kind tooth geometry allows this blade to generate cuts that are chip-free as well as incredibly tidy also in one of the most fragile laminates. However, unlike hollow-face grinds, the LV blade remains sharp also sought after manufacturing applications as well as is quickly serviced. Currently outfitted with EDGE LAST anti-corrosion, sub-micron ideas for longer solution in between sharpenings.

Melamine Veneer type circular saw blades

Usage on: Table Saw, Portable Table Saw, Sliding Table Saw, Vertical Panel Saw. Our Melamine-Veneer blade is developed, for chip-free cutting of great veneers and also melamine whether double-faced or solitary. This will certainly quickly be your preferred blade for all your laminate or veneer tasks. the C-4 wear-resistant carbide suggestion offers you smooth, accurate cuts while lasting longer in between sharpenings.

Miter Box type circular saw blades

| Diameter | teeth | Plate | Kerf | Bore | Grind |

| 9″ | 40 | 0.085″ | 0.131″ | 0.625″ | 5° Alternate Top Bevel; 2° Hook, Wood/Non-Ferrous/Plastic |

| 10″ | 40 | 0.085″ | 0.131″ | 0.625″ | 5° Alternate Top Bevel; 2° Hook, Wood/Non-Ferrous/Plastic |

| 10″ | 48 | 0.085″ | 0.131″ | 0.625″ | General Purpose; 15° Hook |

| 10″ | 60 | 0.085″ | 0.131″ | 0.625″ | Triple Chip Grind; -6° Hook, Wood/Non- Ferrous |

| 10″ | 60 | 0.085″ | 0.131″ | 0.625″ | Radial Trim Alternate Top Bevel; -6° Hook, Wood |

| 12″ | 72 | 0.065″ | 0.095″ | 1″ | Alternate Top Bevel; 10° Hook |

| 12″ | 100 | 0.080″ | 0.11″ | 1″ | Triple Chip Grind; 10° Hook, Wood/Plastic |

| 14″ | 100 | 0.080″ | 0.125″ | 1″ | Triple Chip Grind; 10° Hook, Wood/Plastic |

| 14″ | 100 | 0.080″ | 0.125″ | 1″ | Alternate Top Bevel; 10° Hook |

| 15″ | 100 | 0.090″ | 0.135″ | 1″ | Triple Chip Grind; -6° Hook |

| 15″ | 100 | 0.090″ | 0.135″ | 1″ | Alternate Top Bevel; 10° Hook |

Usage on: Mitre Saw, Compound Mitre Saw, Radial Arm Saw. Particularly created for miter box makers made by Porter-Cable, Ryobi, Makita, Delta, Hitachi as well as DeWalt. These blades are developed to decrease stress on brake systems for longer equipment life. 9″ as well as 10″ CC are flexible for all products. Usage reduced tooth matters for a thicker products.

Plywood type circular saw blades

| Diameter | Teeth | Plate | Kerf | Bore | Grind |

| 8″ | 44 | 0.085″ | 0.131″ | 0.625″ | 10 Tooth and Raker Grind |

| 10″ | 55 | 0.085″ | 0.131″ | 0.625″ | 10 Tooth and Raker Grind |

| 12″ | 66 | 0.095″ | 0.145″ | 1″ | 10 Tooth and Raker Grind |

| 14″ | 72 | 0.109″ | 0.161″ | 1″ | 8 Tooth and Raker Grind, 15掳 Hook |

Usage on: Table Saw, Portable Table Saw, Sliding Table Saw, Radial Arm Saw. The utmost table-circular saw blade for cabinetmakers as well as requiring artisans. The Paymaster is the most effective cupboard blade. It’s optimal for the seasoned woodworker that desires smooth, chip-free cuts in all kinds of products consisting of plywoods, bitboards, soft or tough timbers.

Precision Trim type circular saw blades

| Diameter | Teeth | Plate | Kerf | Bore | Grind |

| 8″ | 40 | 0.085″ | 0.131″ | 0.625″ | Alternate Top Bevel; 10° Hook |

| 8″ | 48 | 0.085″ | 0.131″ | 0.625″ | Radial Trim Alternate Top Bevel; -6° Hook, Wood |

| 8″ | 60 | 0.085″ | 0.131″ | 0.625″ | Alternate Top Bevel; 10° Hook |

| 9″ | 60 | 0.085″ | 0.131″ | 0.625″ | Alternate Top Bevel; 10° Hook |

| 10″ | 40 | 0.085″ | 0.131″ | 0.625″ | Alternate Top Bevel; 10° Hook |

| 10″ | 60 | 0.085″ | 0.131″ | 0.625″ | Radial Trim Alternate Top Bevel; -6° Hook, Wood |

| 10″ | 60 | 0.085″ | 0.131″ | 0.625″ | Alternate Top Bevel; 10° Hook |

| 10″ | 60 | 0.085″ | 0.131″ | 0.625″ | Super Finish Steep Alternate Top Bevel Grind; 10′ Hook |

| 10″ | 80 | 0.085″ | 0.131″ | 0.625″ | Alternate Top Bevel; 10° Hook |

| 10″ | 100 | 0.085″ | 0.131″ | 0.625″ | Alternate Top Bevel; 10° Hook |

| 12″ | 60 | 0.095″ | 0.145″ | 1″ | Alternate Top Bevel; 10° Hook |

| 12″ | 60 | 0.095″ | 0.145″ | 0.625″ | Radial Trim Alternate Top Bevel; -6° Hook, Wood |

| 12″ | 60 | 0.095″ | 0.145″ | 1″ | Super Finish Steep Alternate Top Bevel Grind; 10′ Hook |

| 12″ | 80 | 0.095″ | 0.145″ | 1″ | Alternate Top Bevel; 10° Hook |

| 12″ | 100 | 0.080″ | 0.11″ | 1″ | Alternate Top Bevel; 10° Hook |

| 12″ | 100 | 0.095″ | 0.145″ | 1″ | Alternate Top Bevel; 10° Hook |

| 14″ | 60 | 0.109″ | 0.161″ | 1″ | Alternate Top Bevel; 10° Hook |

| 14″ | 80 | 0.109″ | 0.161″ | 1″ | Alternate Top Bevel; 10° Hook |

| 14″ | 80 | 0.109″ | 0.161″ | 1″ | Super Finish Steep Alternate Top Bevel Grind; 10′ Hook |

| 14″ | 100 | 0.080″ | 0.125″ | 1″ | Alternate Top Bevel; 10° Hook |

| 14″ | 100 | 0.109″ | 0.161″ | 1″ | Alternate Top Bevel; 10° Hook |

| 15″ | 100 | 0.090″ | 0.135″ | 1″ | Alternate Top Bevel; 10° Hook |

| 16″ | 60 | 0.120″ | 0.172″ | 1″ | Alternate Top Bevel; 10° Hook |

| 16″ | 80 | 0.120″ | 0.172″ | 1″ | Alternate Top Bevel; 10° Hook |

| 16″ | 100 | 0.120″ | 0.172″ | 1″ | Alternate Top Bevel; 10° Hook |

| 18″ | 60 | 0.134″ | 0.19″ | 1″ | Alternate Top Bevel; 10° Hook |

| 18″ | 100 | 0.134″ | 0.19″ | 1″ | Alternate Top Bevel; 10° Hook |

Usage on: Mitre Saw, Compound Mitre Saw, Radial Arm Saw. Specifically created for secure, smooth cuts on all radial arm saws. Unfavorable hook angle decreases opportunities of getting hold of or overfeeding. Select the RT Alternate Top Bevel Grind for crosscutting timber and also a cutoff job, the RM Triple Chip Grind blade is optimal for all-round cutting as well as outstanding for reducing non-ferrous steels on slice saws. For the best efficiency on thicker product usage reduced tooth matter, as well as for thinner product usage greater tooth matter.

Radial Arm type circular saw blades

| Diameter | teeth | Plate | Kerf | Bore | Grind |

| 8″ | 48 | 0.085″ | 0.131″ | 5/8″ | Triple Chip Grind; -6° Hook, Wood/Non- Ferrous |

| 10″ | 48 | 0.085″ | 0.131″ | 5/8″ | General Purpose; 15° Hook |

| 10″ | 60 | 0.085″ | 0.131″ | 5/8″ | Triple Chip Grind; -6° Hook, Wood/Non- Ferrous |

| 12″ | 60 | 0.095″ | 0.145″ | 5/8″ | Triple Chip Grind; -6° Hook, Wood/Non- Ferrous |

| 12″ | 60 | 0.095″ | 0.145″ | 1″ | Triple Chip Grind; -6° Hook, Wood/Non- Ferrous |

| 8″ | 48 | 0.085″ | 0.131″ | 5/8″ | Radial Trim Alternate Top Bevel; -6° Hook, Wood |

| 10″ | 60 | 0.085″ | 0.131″ | 5/8″ | Radial Trim Alternate Top Bevel; -6° Hook, Wood |

| 12″ | 60 | 0.095″ | 0.145″ | 5/8″ | Radial Trim Alternate Top Bevel; -6° Hook, Wood |

Usage on: Mitre Saw, Compound Mitre Saw, Sliding Compound Mitre Saw, Radial Arm Saw. Specifically created for risk-free, smooth cuts on all radial arm saws. Adverse hook angle reduces possibilities of getting or overfeeding. Select the RT Alternate Top Bevel Grind for crosscutting timber and also a cutoff job, the RM Triple Chip Grind blade is excellent for all-round cutting and also superb for reducing non-ferrous steels on cut saws. For the best efficiency on thicker product usage reduced tooth matter, as well as for thinner product usage greater tooth matter.

Safety Rip type circular saw blades

| Diameter | Teeth | Plate | Kerf | Bore | Grind |

| 10″ | 20 | 0.085″ | 0.125″ | 0.625″ | Flat Top Grind; 20° Hook |

| 12″ | 24 | 0.095″ | 0.135″ | 1″ | Flat Top Grind; 20° Hook |

Usage on: Table Saw, Portable Table Saw, Sliding Table Saw, Straight Line Rip, Gang Rip Saw. Tough, high-production hole blades for all kinds of strong timber. Chip control style of these blades help in restricting feed prices and also helps in reducing the opportunity of kickback in both soft as well as difficult timbers. European layout.

Sliding Table type circular saw blades

| Diameter | teeth | Plate | Kerf | Bore | Grind |

| 300mm | 60 | 0.085″ | 0.126″ | 1″ | 12째 Hook – SCMI, Griggio |

| 300mm | 60 | 0.085″ | 0.126″ | 30mm | 12째 Hook – Altendorf, Casedai |

| 300mm | 60 | 0.085″ | 0.126″ | 1″ | 12째 Hook – SCMI, Griggio |

| 300mm | 72 | 0.085″ | 0.126″ | 30mm | 12째 Hook – Altendorf, Casedai |

| 350mm | 72 | 0.085″ | 0.126″ | 30mm | 12째 Hook – Altendorf, Casedai, Holz-Her |

Usage on: SCMI, Griggio. APPLICATION: Cutting melamine-faced as well as plastic-laminated chipboard on solitary or both sides. Suit with 2 item split or conelike work racking up blades. Three-way Chip Chamfered Raker Grind.

Solid Surface type circular saw blades

| Diameter | Teeth | Plate | Kerf | Arbor | Grind |

| 7.25″ | 40 | 0.072″ | 0.120″ | 0.625″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 8″ | 40 | 0.085″ | 0.120″ | 0.625″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 8″ | 48 | 0.085″ | 0.120″ | 0.625″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 10″ | 48 | 0.085″ | 0.120″ | 0.625″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 10″ | 60 | 0.075″ | 0.120″ | 0.625″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 12″ | 60 | 0.095″ | 0.130″ | 1″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 12″ | 72 | 0.095″ | 0.130″ | 1″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 14″ | 72 | 0.109″ | 0.149″ | 1″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 300mm | 60 | 0.095″ | 0.135″ | 30mm | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 300mm | 72 | 0.085″ | 0.135″ | 30mm | Modified Top Bevel; -6deg Hook to + 10deg Hook |

Super Finish type circular saw blades

| Diameter | Teeth | Plate | Kerf | Arbor | Grind |

| 7.25″ | 40 | 0.072″ | 0.120″ | 0.625″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 8″ | 40 | 0.085″ | 0.120″ | 0.625″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 8″ | 48 | 0.085″ | 0.120″ | 0.625″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 10″ | 48 | 0.085″ | 0.120″ | 0.625″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 10″ | 60 | 0.075″ | 0.120″ | 0.625″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 12″ | 60 | 0.095″ | 0.130″ | 1″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 12″ | 72 | 0.095″ | 0.130″ | 1″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 14″ | 72 | 0.109″ | 0.149″ | 1″ | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 300mm | 60 | 0.095″ | 0.135″ | 30mm | Modified Top Bevel; -6deg Hook to + 10deg Hook |

| 300mm | 72 | 0.085″ | 0.135″ | 30mm | Modified Top Bevel; -6deg Hook to + 10deg Hook |

Usage on: SCMI, Griggio. APPLICATION: Cutting melamine-faced as well as plastic-laminated chipboard on solitary or both sides. Suit with 2 item split or conelike work racking up blades. Three-way Chip Chamfered Raker Grind.

Super Finish type circular saw blades

| Diameter | Teeth | Plate | Kerf | Arbor | Grind |

| 10″ | 60 | 0.085″ | 0.131″ | 0.625″ | Super Finish Steep Alternate Top Bevel Grind; 10° Hook |

| 12″ | 60 | 0.095″ | 0.145″ | 1″ | Super Finish Steep Alternate Top Bevel Grind; 10° Hook |

| 14″ | 80 | 0.109″ | 0.161″ | 1″ | Super Finish Steep Alternate Top Bevel Grind; 10° Hook |

Thin Kerf type circular saw blades

| Diameter | Teeth | Plate | Kerf | Arbor | Grind |

| 8-1/4″ | 24 | 0.050″ | 0.080″ | 0.625″ | Triple Chip Grind; 20° Hook |

| 8-1/4″ | 30 | 0.050″ | 0.080″ | 0.625″ | 4 Tooth and Raker Grind (4ATB1 Raker) Planer; 15° Hook |

| 8-1/4″ | 40 | 0.050″ | 0.080″ | 0.625″ | Alternate Top Bevel; 10° Hook |

| 8-1/4″ | 60 | 0.050″ | 0.080″ | 0.625″ | Alternate Top Bevel; 10° Hook |

| 10″ | 24 | 0.060″ | 0.093″ | 0.625″ | Triple Chip Grind; 20° Hook |

| 10″ | 40 | 0.060″ | 0.093″ | 0.625″ | Alternate Top Bevel; 10° Hook |

| 10″ | 50 | 0.060″ | 0.093″ | 0.625″ | 4 Tooth and Raker Grind (4ATB1 Raker) Planer; 15° Hook |

| 10″ | 60 | 0.060″ | 0.093″ | 0.625″ | Alternate Top Bevel; 10° Hook |

| 10″ | 80 | 0.070″ | 0.099″ | 0.625″ | Alternate Top Bevel; 10° Hook |

| 10″ | 60 | 0.070″ | 0.099″ | 0.625″ | Triple Chip Grind; 10° Hook, Wood/Plastic |

| 10″ | 80 | 0.070″ | 0.099″ | 0.625″ | Triple Chip Grind; 10° Hook, Wood/Plastic |

| 12″ | 24 | 0.065″ | 0.095″ | 1″ | Triple Chip Grind; 20° Hook |

| 12″ | 48 | 0.065″ | 0.095″ | 1″ | Alternate Top Bevel; 10° Hook |

| 12″ | 72 | 0.065″ | 0.095″ | 1″ | Alternate Top Bevel; 10° Hook |

| 12″ | 100 | 0.080″ | 0.110″ | 1″ | Triple Chip Grind; 10° Hook, Wood/Plastic |

| 12″ | 100 | 0.080″ | 0.110″ | 1″ | Alternate Top Bevel; 10° Hook |

| 14″ | 100 | 0.080″ | 0.125″ | 1″ | Triple Chip Grind; 10° Hook, Wood/Plastic |

| 14″ | 100 | 0.080″ | 0.125″ | 1″ | Alternate Top Bevel; 10° Hook |

| 15″ | 100 | 0.090″ | 0.135″ | 1″ | Triple Chip Grind; -2° Hook |

| 15″ | 100 | 0.090″ | 0.135″ | 1″ | Alternate Top Bevel; 10° Hook |

Thin Kerf circular saw blades; 15in. Dia., Grind: MC (Triple Chip Grind; -6 deg Hook), 100 Teeth, 0.09 in. Plate, 0.135 in. Kerf, 1in. Arbor. Usage on: Table Saw, Portable Table Saw, Mitre Saw. Stunning surface cuts with much less waste and also much less feed pressure. These blades need much less horsepower, as well as conserve useful product. An exceptional selection for the differentiating woodworker and also for smaller-sized saws. NOT suggested for radial arm saws! Usage severe treatment abreast, device upkeep, and also procedure. Constantly make use of saw guards. Get in touch with the maker for suggested adjustment if guards are as well thick to fit a Thin Kerf blade. You might buy a blade below or call us and also have our design team style a personalized blade for your product, maker, and also details usage.

Vertical Panel type circular saw blades

Usage on: Interwood. APPLICATION: Cutting melamine-faced as well as plastic-laminated chipboard, without racking up blades. Upside down “V” work.

| Diameter | teeth | Plate | Kerf | Bore | Grind |

| 220mm | 64 | 0.085″ | 0.126″ | 30mm | Vertical Panel |

| 8″ | 60 | 0.085″ | 0.118″ | 5/8″ | Hook -6, Safety Speed Cut, Milwaukee |

| 250mm | 60 | 0.085″ | 0.126″ | 30mm | Hook -6, Interwood |

| 300mm | 72 | 0.085″ | 0.126″ | 30mm | Hook -6, Striebig, Holz-Her |