Air Chisel Bit

Pneumatic Flat Head Oval-shaped Air Hammer Bit Smoothing Chisel Extended Length Impact Tool for Formation

- Carbide-tipped tools feature cutting edges of carbide for wear resistance and a steel shank for toughness.

- Spear point carbide tip shape design for extreme drilling rough tile, ceramics, porcelains and glass, etc.

- Round shank is designed for use in power drills, drill presses, and boring machines.

- Chrome plated for high corrosion resistance and low friction.

- Best result with lower rpm and good cooling with water, vinegar and turpentine.

- Product Details

- Factory

- Material

|

Product name

|

Pneumatic Flat Head Oval-shaped Air Hammer Bit Smoothing Chisel Extended Length Impact Tool for Formation

|

||

|

Material

|

40Cr Steel

|

||

|

Process

|

Automatic CNC Machine Processing

|

||

|

Shank

|

Round shank (Quick Change Hex Shank and Three-Flat Shank are available )

|

||

|

Surface

|

Chrome Plated (Sand Blasted, Nickel Plated, Titanium Coated, and Black Oxide are available

|

||

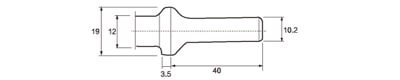

| Product Size | |||||

| Pneumatic Chisel |  |

||||

| Item | Head Diameter (mm) | Total Length (mm) | Picture | ||

| Pannel Cutter Chisel | / | 165 |  |

||

| Scraper Bend Chisel | 32 | 165 |  |

||

| Taper Punch Chisel | / | 165 |  |

||

| Punch Chisel | / | 165 |  |

||

| Flat Chisel | 19 | 165 |  |

||

| Double Enge Cutter Chisel | / | 165 |  |

||

| Tail Pipe Cutter Chisel | 28 | 165 |  |

||

| Sheet Material Chisel | / | 165 |  |

||

| * Custom-tailor would be available against customers’ requirements | |||||

Factory

1. Moil Point Breaker Hammer Bit is ideal for starting holes in concrete slabs and for general chipping and demolition work.

2. Flat Chisel is ideal for general chiseling and breaking work in brickwork, concrete, and loose stone.

3. Gouge Chisel is ideal for cutting narrow channels into the concrete.

4. Fully heat treatment improves core strength for maximum durability and extended life.

5. Forged from superior-grade steel, the working points of our chisels can be re-sharpened for longevity

6.Compatible with all SDS-Plus style chucks.

1. Suitable for hammer machines

2. Other sizes are available upon your request.

3. We have a strict quality control system, to ensure quality stable.

4. The inspection report provided available.

5. Packing, Artwork design free.

How to Use:

■ Follow carefully the instructions given in the machine handbook.

■ Never fit a diamond dish/cup wheel which is too loose or too tight on the flange.

■ Tighten only with the tool supplied with the machine.

■ Ensure the wheel is properly gripped to prevent slippage, but do not tighten with excessive force. Never use a hammer.

■ Keep flanges and screw threads clean and free of burrs and rust.

■ Replace distorted or damaged flanges before fitting the wheel.

For your Safety:

We recommends the use of following personal protective equipment:

■ Eye protection

■ Ear protection (ear sets)

■ Hand protection (gloves)

■ Lung protection (dust mask, also called respirator)

Important Note:

Never remove the protective machine guard and make sure it is properly adjusted to deflect debris away from you.

Ensure that no other person is at risk, especially near the machine while working.