Hammer Manufacturers

- Why Tenyu Tools Is the Best Hammer Manufacturer For You?

- You’ll have a guarantee that all our products are OEM

- All your orders will arrive within a 2 to 3-week timeframe, guaranteed!

- Hammers can be made from different types of materials

- We can accommodate all shapes and sizes for hammers for industrial use

- Your hammers will be twice as durable as your regular hammer

- Our hammers are treated and strengthened fully

- Grips and handles are engineered perfectly

Business Advantages in Choosing Tenyu Tools’ as Your Hammer Manufacturer

You can consider us here at Tenyu Tools, Co., Ltd., to:

Be your hammer manufacturer wherever you are in the world.

A lot of our clients are spanning from various parts of the planet, and they continue to trust us whatever type of hammer they need.

Tenyu Tools’ hammers are made from the finest and the purest of materials, sourcing it from the most trusted and the most reliable suppliers and manufacturers, too.

Unlike other hammer manufacturers, Tenyu Tools Co., Ltd. can give you the guarantee that we can give you whatever shape, form, size, and dimensions you want your hammers to be.

You can find a ton of benefits and advantages in choosing us here at Tenyu Tools as your hammer manufacturer.

Some of the benefits and advantages known to many businesses and clients include:

- Higher rate of production using our hammers

- Guaranteed safety and security of your people

- Better quality of products using our hammers

- You can choose from all the different packaging options we have

- Many more!

Applications of Our Hammers

If you initially thought that our hammers are only used for its regular or traditional use, think again!

The overall quality of our industrial hammers make it one of the best, the most powerful, and the most functional!

Whether you’re involved in the business of making these hammers, or if you’re going to resell it, you can place your full and your complete trust in us here at Tenyu Tools Co., Ltd. to provide whatever hammer you need!

Some of the most common business sectors and industries that make use of our hammers include, but are not limited to:

- Electrical Industry

- Landscaping Sector

- Cargo, Freight, and Transportation Sector

- Brick and Blockmasonry Sectors

- Construction or Structural Industry

- And Many More!

Business Capabilities of Tenyu Tools

Unlike your friendly neighborhood hammer manufacturer, Tenyu Tools Co., Ltd. will never leave you out in the open, questioning how you can take advantage of the hammers you can get and purchase from us.

Our expertise allows us to produce and manufacture the best and the highest qualities of hand and power tools in the market. In fact, you can purchase other tools from us, such as diamond cutting blades, concrete drill bits, nibbler cutters, and many more!

The best part about working with us is the fact that we can specify the hammers you require! Thanks to our full on Research & Development (R&D) team, we’ll be able to craft up the best types and the best qualities of hammers you need!

Give us a quick call and we’ll be more than happy to give you a free estimate of all the products you need!

Hammer Manufacturer – The Comprehensive FAQ Guide

In case you find yourself interested in learning about hammers, you’re just in the right guide! Whether you’re involved in the business of selling custom hammers or if you want to order hammers wholesale, we got you!

Today, we won’t just guide and assist you to find the best hammer industrial manufacturers in the market, we will also walk you through how you can consider hammers to be the best product in your arsenal, what factors you need to consider in purchasing hammers, and many more!

Before we dive straight into that particular topic, let us first try to understand the essence of hammers.

What Materials Are Used to Make Hammers?

Have you ever wondered the type of tools and materials hammer manufacturers used to make hammers?

In today’s time, you will find a ton of different materials in making hammers. However, the most common of them are made and comprised of material that has high levels of carbon and are heat-treated for the durability and the strength.

Apart from the usual steel, though for the handle, several hammer manufacturers and hammer suppliers experimented to create hammers from a wide variety of materials, some of which include:

- Metal

- Plastic

- Wood

- Rubber

- And Other Similar Materials

Industrial hammers, though, usually incorporate the combination or the mixture of different types of materials – treated rubber for the weighted head among others.

How Are Hammers Made?

Various types and kinds of hammers undergo different manufacturing processes.

Add the fact that some suppliers and wholesalers practice varying hammer manufacturing procedures, you really wouldn’t be able to see the same thing.

However, there’s a particular hammer manufacturing process that’s considered to be the basis of all other methods.

Step 1: Creation or Making of the Head

Most industrial hammer manufacturers and wholesalers start by creating or making the head, and they do it by finding or sourcing for the right type of material.

In this context, we’ll stick to steel because it’s the most common – and for it, this piece of steel is melted at around 1,200 to 1,300 degrees Celsius.

During the melting process, the steel will be softer and it will be easier to mold, shape, and form.

It’s not lifted up immediately when it’s molded, in fact, it’s left there to cool off for about half an hour and when it cools down by at least 20%, they usually take it off to fix and resolve some imperfections.

Step 2: Making the Handle

When the head is fabricated and is produced, the next step or the next phase of the process would be the creation or the making of the handle.

Before that, though, the manufacturer will first prepare all materials and things that’ll be needed. Oftentimes, just a regular piece of wood will be enough, but not all the time.

In fact, this particular step in the hammer manufacturing process is what’s considered by many manufacturers to be their holy grail because it will decide whether or not the hammer will be high-quality.

The chosen material for it, whether it’s wood, plastic, or rubber, would then be cut and shaped depending on the desired form. Going with the process further, it’s sanded down and it’s polished, preparing it for the last and final step, which is…

Step 3: Combining or Assembly of the Handle + Head

Once the handle and the hammer head is finalized, the last and the final step is to combine and to unite the two.

The material will go through the eye, then the handle is pressed abruptly to the eye. A piece of the material used for the handle will be driven down to the wedge and when it’s stretched, the wedged material will go through flawlessly.

That’s the usual and the traditional way of the hammer manufacturing process. Again, some suppliers and some manufacturers might do it differently, but, this is considered as the basic and the simplest method to do.

Different Types of Hammers

There are quite a few types of hammers that you might not know by name or by term, but you know when you have a first look at them.

To help you even further, here are some of the most popular types of hammers (industrial and non-industrial).

Claw Hammer

A claw hammer is the hammer type that you regularly see on the internet or being used by carpenters. It’s not right to say it, but claw hammers are actually the most basic type of hammer there is.

Cross Peen Hammer

Cross peen hammers are the hammer types that contain a peen that is placed crosswise the length of the overall shaft.

Straight Peen Hammer

A straight peen hammer, on the other hand, is a type of hammer that you’ll know because it has the head parallel to the handle.

Ball Peen

Ball peen hammers are hammers that have rounded peens on the opposite end of the part that you use to strike nails and other types of materials.

Club Hammer

A club hammer is the hammer type that’s similar on its two (2) ends; it’s also known as a mini-sledge hammer or Thor hammer.

Sledge Hammer

Sledge hammers are hammers that are usually flat and are used for work involving demolition or destruction.

Special Industrial Hammers

Lastly, these special industry hammers are hammers that are often mechanical and electrical. You’ll find them most useful in business sectors and industries that require specifically accurate and precise work.

These are some of the most common and the most-used types of industrial hammers in the market.

What is an Industrial Hammer?

An industrial hammer is basically a hammer used in the industrial sector.

Just like any other type of hammer – whether it’s a sledge hammer, a club hammer, or other types, you can consider it as an industrial hammer if you’re going to use it in the industrial sector or industry.

Some people argue that an industrial hammer is a type of milling or grinding machine that’s usually used to cut or to reduce the size of particular aggregate materials into smaller and much more workable pieces.

Nevertheless, these types of hammers are just regular hammers used in the industrial sector.

History of Hammers

Before the age of multiple hammer manufacturers in the world, when did the first hammer come to life?

How did the purchasing of hammers wholesale become one of the biggest business industries across the globe? And quite importantly, what was the function of the hammer before the function we currently use it for?

Based on scientific study, several archaeologists have discovered that the “hammer” tool is a tool that has been used by people 3.3 million years back and astonishingly, the hammer’s function has never changed ever since.

When steel was discovered or about the year 1500s, the first-ever hammer used for industrial applications came to life.

It was not until the 1760s where a few touches of hammer manufacturing has been introduced; it was when the widespread production of hammers have been seen.

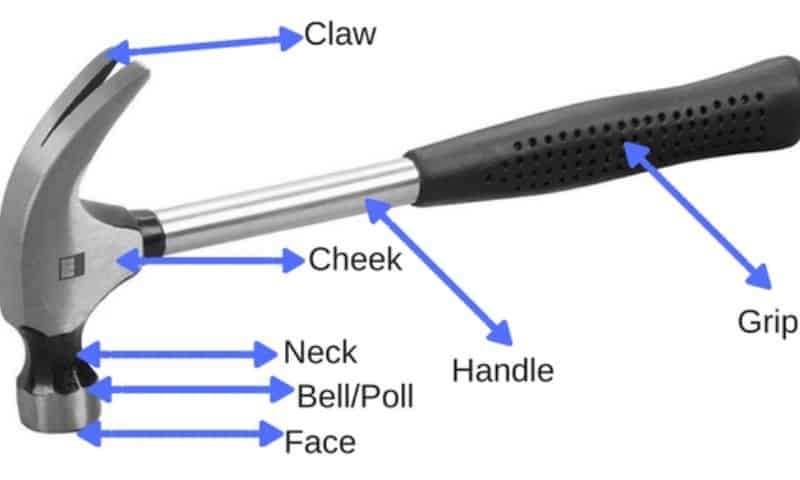

What Are the Parts of a Hammer?

In case you’re interested in understanding the composition of a hammer, here’s a quick and simple list of the different hammer parts.

| Hammer Parts | Function |

| Face | It is the hammer part that you use for striking. |

| Neck | The neck is the part of the hammer that connects the entire head to the handle. |

| Head | The head of a hammer is part of the two (2) primary components of the hammer – head and handle. |

| Peen | The peen is the hammer part that you’ll see at the opposite end of the face. |

| Cheek | The cheek of the hammer is the hammer part that adds supports to the connection of the head to the handle. |

| Eye | The eye is the made up part that you can find at the bottom-part of the head, and it’s the one that slips through the handle. |

| Handle | The handle is the hammer part that people touch to use the hammer. It’s one of the two (2) primary hammer components. |

| Grip | Lastly, the grip is the complementary part that helps with the gripping or the handling of the person, it’s attached at the handle. |

These are all the different hammer parts existent! These nine (9) parts are what makes up the hammer that you and me have known, ever since we were kids!

Ball Peen Hammer vs. Claw Hammers

A lot of people get confused about the hammer type they need to use for a particular job.

Now, in order for you to have a better and a clearer understanding of it, let’s discuss what ball peen and claw hammers are thoroughly.

A ball peen hammer is the type of hammer that has a round-shaped head, in which its purpose is to shape the surface of the metal – and this particular process is known as “peening.”

You can use this particular hammer type in quite a lot of different things, among them include:

- Shaping or in forming steel or metal

- Hardening the density by lightly hammering it

- Smoothing edges of fasteners

- Closing rivet openings

- And many more!

Claw hammers, on the other hand, are hammers where the other end is shaped like that of a claw. Its particular use or purpose is to remove nails from wood.

With the primary use of claw hammers being to remove nails off of wood, you can also use it to dismantle or take apart assemblies that are joined together by nails, loose screws, etc.

Can You Order Custom Hammers Wholesale?

If you’re ordering hammers wholesale or if you’re trying to order hammers custom made, chances are, you’ll be asked for a sketch of what you want your custom hammers to look like.

But yes, several hammer manufacturers are offering hammers wholesale, and they’re doing it by giving the best and the most discounted prices in the market.

Chinese custom hammer suppliers are often the go-to solution by many businesses and companies worldwide, as well as other power and hand tools.

So, if you find yourself looking for high quality hammers wholesale and custom made, you can never go wrong in choosing or in working with a Chinese hammer manufacturer.

Why Are There Different Sizes of Hammers?

Purchasing hammers wholesale would require you to understand that different hammers have different sizes.

When you’re speaking with hammer industrial manufacturers and you’re trying to get or order custom home-use or industrial hammers, they’ll ask you for the size you want your hammers to be.

What do you say? To help you with it, all hammers actually come in a series of sizes. These sizes will range between eight (8) to about forty-two (42) ounces. The weight of the hammer refers to the hammer head, not the overall tool along with the handle and the grip.

The lighter the hammer, the more it is inclined for household and home use like personal carpentry, for art, etc. But, if a hammer is maxed at 42 ounces – sometimes even more – it’s used for professional projects or for industrial applications.

What Are Brass Hammers Made To Do?

More often than not, brass hammers point directly to a specific hammer type – the club hammer.

But, it’s not just limited to that as some hammer manufacturers create and produce straight peen hammers, cross peen hammers – even brick hammers from brass. What is it really for?

Brass is actually a type of material that’s softer than steel because it can easily deform. So, you can expect brass hammers not to be used in rough environments such as in the structural or the construction industry, the demolition industry, and those of the likes.

Instead, it’s used in skill-specific applications, some of which include:

- Gunsmith Industry

- Electrical Industry (Brass does not cause sparks)

- Petrochemical and Chemical Industry (Brass does not cause chemical reactions)

- Plumbing Industry (It won’t damage pipes and threads)

If you initially thought that brass hammers offer better strength and higher durability, think again.

What is a Blacksmith Hammer?

A blacksmith, also referred to as a “metalsmith” is an expert in the forging or the creation of materials with the use of steel, iron, or other types of metal.

It could be anything from forging gates, grills, railing, furniture, weapons, etc. And for the processes they’ll perform, they would need a hammer – thus, the blacksmith hammer.

Contrary to what a lot of people believe in, there’s actually not a specific type of hammer used by blacksmiths.

As a matter of fact, blacksmiths would have to determine a particular job or project, then choose which hammer industrial type would befit it.

But, among the most common hammer types that blacksmiths use the cross peen hammer is the most popular. This is because it has a straight flat angle, which easily allows blacksmiths to hammer with precision and accuracy.

Apart from that, blacksmiths also use the straight peen hammer and the sledge hammer for various applications.

What is the Best Weight For a Blacksmith Hammer?

Some hammer manufacturers often argue that blacksmith hammers don’t really need to be at a specific weight.

But, experienced and seasoned hammer suppliers recommend blacksmith hammers or cross peen hammers to be at a weight that’s about 0.9 to 1.4 kg or 2 to 3 pounds, which is ideal for continuous use (using without stoppage), with a good level of weight.

How Do You Choose an Industrial Hammer?

Choosing your industrial hammers would often involve asking questions.

If you’re a beginner in the industry and you’re not sure what questions you should ask, we’re here to guide you!

There are several things you have to ask your hammer manufacturer about the hammer you want before you make the purchase.

Whether you’re going to use it as a household hammer or you’re involved in the business of selling it, these tips can help you ease your decision of choosing an industrial hammer.

Do You Want a Modern-Style or a Classic-Style Hammer?

Most hammer manufacturers will ask you whether you want a hammer in the classic style or you’re more interested in a more modern type of feel.

For this, you have to contact your hammer manufacturer and choose depending on what your wants and needs are.

On the other hand, if you’re looking for a custom hammer, you need to inform the hammer supplier you’re working with and submit a CAD file so they know what exactly it is you’re looking for.

Decide on whether you’ll go for a classic-style hammer or a modern-style hammer, that’s the first thing to check out on your list.

Look At Certain Features

The next big step you can take is to check and look at the features of the hammer.

Try to ask the hammer manufacturer you’re working with about this because they’ll most likely have an answer to your question.

Some of the most common features that hammer manufacturers try to achieve include:

- Durable and highly-resistant face that does not crack during continuous impact

- Lightweight but heavy-duty

- Easier grip (formed and bent grip) but the impact and the results remain constant

- Sharpened and highly-robust design specifically made for heavy-duty use

Are They Durable Enough?

Last but definitely not the least would be the question that you can consider to be the most influential factor in choosing an industrial hammer – are they durable enough?

9 times out of 10, your hammer manufacturer will tell you that it is. To make sure of that, ask them:

- Would the handle remain steady even when the head is starting to wear out?

- Are all the sides and angles of the head engineered perfectly to avoid cracks and scratches?

- What type of heat treatment was done to the head of the hammer?

These are actually the best tips on how you can be sure of the hammers wholesale that you’ll be purchasing!

But before choosing a hammer, isn’t it just right to know which the best hammer manufacturer is?

How Would You Choose a Hammer Manufacturer?

If you’re purchasing hammers wholesale, it’s just right to choose the perfect hammer manufacturer for the job. So, before purchasing hammers wholesale, how do you choose the hammer supplier to work with?

There are a couple of things you can note for you to land working with the best hammer suppliers. Some of these include:

- Check out the hammer manufacturer’s website and look at clients’ previous feedback

- Have a digital tour of the hammer factory to see how they produce and manufacture it

- If you’re looking for hammers custom made, research about their R&D department

- Try to dig deep into how they perform hammer wholesale manufacturing

Which Hammer Wholesale Supplier Should You Work With?

Cut your worries of how you can work with the best hammer wholesaler by working with us here at Tenyu Tools, Co. Ltd!

By far, we’ve been China’s top pick for all custom hammer wholesale orders! We are housed with the best and the most experienced engineers and blacksmiths to create accurate and precise custom hammers!

Other than hammers, you can also trust us to supply you with other custom tools such as drill bits, circular wood blades, auger bits, grinding wheels, and many more!

Don’t waste time by looking at other options for your custom hammers or if you’re ordering hammers wholesale – contact us here at Tenyu Tools and get the best and the highest quality of custom hammers wholesale!

Talk to us and we will send a free quotation or a free estimate your way!