Industrial Grinding Wheel

- Why Choose Tenyu Tools’ Industrial Grinding Wheels?

- Our industrial grinding wheels will be capable of removing paint, glue, etc.

- You can get our industrial grinders in the best and highest quality available

- For over 15 years, we’ve been offering competitive rates for our industrial grinders

- You’ll never regret trusting our R&D Team for customizing your orders!

Tenyu Tools: Your Premier Industrial Grinding Wheel Manufacturers

Tenyu Tools’ industrial grinding wheels have been the best and the most trusted in the whole of the country.

The vast array of applications you can have for it is what gives it the most usefulness. If you need an industrial grinding wheel for gemstones like diamonds; concrete and other masonry; or carbide tips, Tenyu Tools’ industrial grinding wheels will be the best choice for you!

Apart from those sectors, you can also choose to retail or to merchandise our products! Whatever type of use you need it for, you can trust Tenyu Tools Co., Ltd!

We work hand-in-hand with resellers, marketers, and hardware shop owners. You can become one of the 990+ merchants and businesses we work with!

Tenyu Tools’ Business Advantages

For more than 15 years in the market, Tenyu Tools Co., Ltd. never failed to produce and/or manufacture high-quality industrial grinding wheels.

If you need to produce high volumes of industrial grinding wheels, you can trust us. Even in that speed, the quality of all our products is never compromised.

Whether you’re in Europe, Asia, in the Americas – and Africa, our industrial grinding wheels are accepted.

We can talk to you about customizing your grinding wheels, as well as finalizing the design and the overall physicality of what you have.

Don’t think twice in working and in choosing us here at Tenyu Tools Co., Ltd. for the industrial grinders you need.

Our goals never changed and we’re always open to do business with everyone interested in what we offer.

Shoot us an email and get a free estimate of the industrial grinding wheels you need! Get extreme quality industrial grinding wheels at a competitive rate!

- Manufacturing Machine for Industrial Grinding Wheel

- Production Process

- Industrial Grinding Wheel Using

Industrial Grinding Wheel – The Comprehensive FAQ Guide

Out of the many different types of industrial grinding wheels, how do you choose the best one? Today, we’ll be discussing that!

This guide will primarily focus on industrial grinding discs. You will learn what they are, what you need to know before purchasing – to selecting the best industrial grinding wheel manufacturer.

Without further ado, let’s head onto the guide!

What is a Grinding Wheel Used For?

Generally, a grinding wheel is a multifunctional tool you can use for industrial purposes.

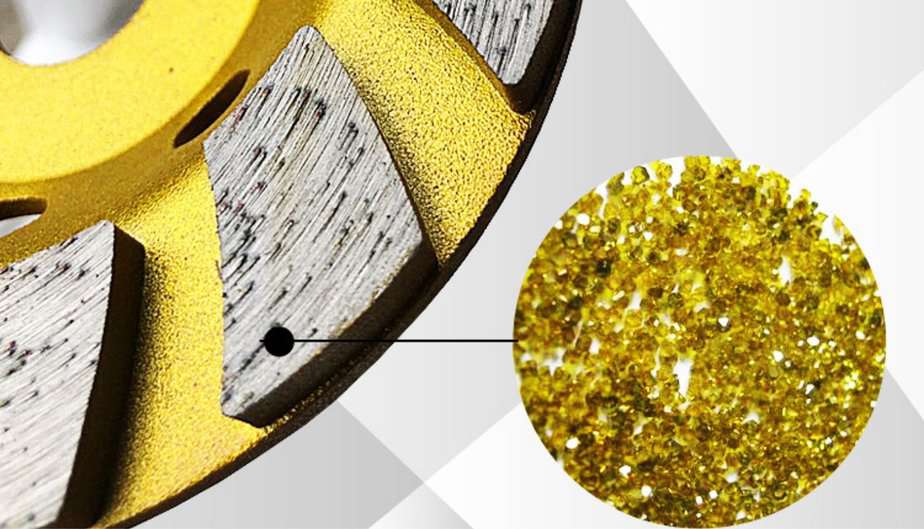

Example of an industrial grinding wheel Tenyu Tools Co., Ltd. is offering

You can use it to grind, cut, and to finish or polish metals, steel, and other materials.

What Does the “Grade” Mean in an Industrial Grinding Wheel?

Grades of an industrial grinding wheel basically determine the tightness of the abrasive’s bond.

Knife being polished using an industrial grinding wheel (sharpening or polishing)

Don’t be confused – it’s not the hardness of the grains of the abrasives.

The Different Types of Grinding Wheels

In the market today, there are a few types of industrial grinding discs. They include:

Straight grinding wheel that has already been worn out

Straight Grinding Wheels

They’re the most typical and the most common type of grinding wheel in the market.

You see them all over the world in various businesses and sectors. Straight grinding wheels are commonly used for sharpening and for enhancing various tools such as blades and chisels.

Large Diameter Grinding Wheels

Akin to what straight grinding wheels are, large diameter (LD) grinding wheels are larger in size.

Their purpose is similar to straight grinding wheels, but they’re capable of grinding down large objects’ exteriors.

FUN FACT: You can manufacture an LD grinding wheel that can have a diameter of up to 38”.

Grinding Cup Wheels

From the term alone, an industrial grinding cup wheel would have a concave physicality.

Its main use is to help you polish or finish up concrete or stone. Thus, you can use it for sharpening or other finishing applications.

Grinding Dish Wheels

Similar to grinding cup wheels, dish grinding wheels have thinner and shallower edges.

The only advantage you can get from it vs. cup wheels is that it can fit areas cup wheels can’t.

Cutting Face Grinding Wheels

They’re the type of grinding wheels you can use to grind away almost any type of object.

Almost always narrow in physicality, you can use it to shape teeth of saws or to cut tile.

Segmented Grinding Wheel

It is a type of grinding wheel that can be manufactured in different styles such as:

- 2A2T

- 1A1

- 6A2

- Etc

Segmented grinding wheels have different sections that are segmented and divided. You’ll use segmented grinding discs for removing or for grinding big chinks of materials without any damages.

How Do You Read an Industrial Grinding Wheel’s Markings?

Reading or understanding the markings or labels of a grinding wheel is challenging at first.

A simple analogy of what information are given in an industrial grinding wheel’s label

But, all abrasive or industrial grinding discs contain the following marks and information:

- Type of Wheel

- Type of Size

- Specification of the Wheel

- Operation Speed

- Usage Restrictions

- Other Information (Non-Safety Related Information)

ISO (Wheel Type)

Firstly, the type of wheel will have markings as an ISO number; this determines the shape of the wheel.

For instance, an ISO Type 1 Wheel would mean it’s a thick disc with the shape of a wheel.

Wheel Size

Secondly, the size of the wheel will always be marked in millimeter (mm) dimensions.

Wheel Specification

Thirdly, the specification of the wheel will appear as a combination of number sand letters. To give you a concrete example: FA 20 V 2 EP

Here’s a table that would help you determine what the specifications mean:

| Marking | Marking Code |

| Abrasive Material Type | WA – White Aluminum Oxide A – Regular Aluminum Oxide 19A – Combination of WA and A ASD – Synthetic Diamond and Metal Coating SD – Synthetic Diamond SA (HA) – Single Crystal Aluminum Oxide FA – Semi-Friable Aluminum Oxide PA – Pink Aluminum Oxide AZ – Zirconium Oxide 23A – Mixture of A and SA (HA) GC – Green Silicone Carbide C – Black Silicone Carbide RC – Mixture of GC and C |

| Grit Size | 10, 12, 14, 16, 20 (Coarse) 600, 800, 100, 1,200 (Fine) |

| Grade of Metal | A, B, C, D, E (Soft) V, W, X, Y (Hard) |

| Structure | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14 (Dense) |

| Bond Type | E – Epoxy EP – Electroplated M – Metal V – Vitrified B – Resinoid R – Rubber O – MgO |

Restrictions

The restrictions you will see on the markings are also settled via code. In most cases, it’ll be in a graphic form.

| Restriction Code | Meaning |

| RE1 | Not allowed for manual of hand-held grinding |

| RE2 | Not allowed for manual or hand-held cutting machines |

| RE3 | Not advised for wet grinding |

| RE4 | Only allowed to be used within an enclosed area |

| RE6 | Not allowed for face grinding |

Expiry Date

More often than not, the expiry date of industrial grinding wheels would be within three (3) years from the date of manufacturing.

You’ll see this usually near the boring hole (middle) in the following format: MM/YYYY.

Those are the markings or the labels you’ll see on all industrial grinding wheels. Don’t be confused! It’s easy-to-understand!

What are Grinding Machines?

Grinding machines – or grinder, for short – is a type of power tool or machine tool you use for grinding.

A type of an industrial grinding machine where you mount or load grinding discs/wheels

It’s the machine where you mount a grinding wheel for either manual or automated grinding.

What is a Type 1 Industrial Abrasive Wheel?

They’re the kind of industrial grinding wheel where the thickness, hole size, diameter, and the dimensions must only be used and utilized on the surface of a material.

How Are Industrial Grinding Wheels Manufactured?

The manufacturing process or procedure of industrial grinding wheels isn’t rocket science.

A part of the manufacturing process of industrial grinding wheels

As a matter of fact, you’ll be able to understand it easily. The general structure of a grinding wheel’s manufacturing goes like this:

- The very first step in manufacturing an industrial grinding wheel is to source out and mix all the materials and ingredients.

- After that, the next step is to mold the wheel to the desired shape.

- What you need to do after that is to compactly press the disc to arrive at the shape needed. The force needed would be between 100 to 5,000 pounds per square inch (PSI); it’ll be from ten (10) to thirty (30) seconds.

- After it gets removed from the press, the final wheel shaping will take place.

- The wheel then needs to be fired to melt and bond the abrasives onto the disc. Temperatures for a resin bond would be between 149 to 204 degrees Celsius; and vitrified bonds to be at 927 to 1,260 degrees Celsius.

- Finally, the wheels will get its final inspection before it’s finished. In this stage, everything is checked. From modifying the boring hole, balancing of the wheels for vibration, and finalization for the markings.

Grinding Wheels vs. Cut-Off Wheels

While they’re typically the same, you wouldn’t want to use a grinding wheel for cutting.

Cutting wheel being used to work or cut on a strip of steel

Cut-off or cutting wheels are designed and engineered to cut, not to grind. Therefore, they don’t have that strength you need for grinding.

Grinding wheels, on the other hand, are thicker and stronger. But, you need to note that industrial grinding discs are only for working on the periphery or the surface of a material.

What are Bench and Pedestal Abrasive Wheels?

They’re industrial grinding discs you use for a wide range of actions. You can use them for sharpening, shaping, deburring – and in removing or cutting.

You use a bench grinding wheel for bench machines and equipment; and pedestal abrasive wheels for a specific type of machine.

How Can I Choose the Right Industrial Grinding Wheel?

Before you decide on which industrial grinding wheel to purchase, you need to take note of the following:

Abrasives, Grains, and Grits

These are characteristics you’ll easily see on the markings or on the specifications of industrial grinding wheels.

Knowing what abrasives, grits, and grains you need would allow you to determine the quality, strength, and the overall ability of the grinding wheel you are to purchase.

Shape of the Wheel

Not all grinding wheels and discs have the same shape. There are straight wheels, cupped, dished, etc.

Choosing the right and the correct type of wheel will give you the functionality and the efficiency you need.

Bond Type

The grade or the bond type would mean a lot in choosing the grinding wheel to go for.

You need to choose the correct type of bond to ensure that your results would be what you want.

In case you’re not sure of what this is, you can try to talk to the manufacturer of your choice about it.

If you successfully combine all of these, you’ll easily be able to find the best and the most appropriate type of grinding disc for your operations or your business.

Are Abrasive Wheels and Grinding Wheels the Same?

Abrasive wheels discuss the surface of the grinding wheel. Grinding wheels determine the type of operations your wheels will be functional for.

Abrasive wheels stacked up with covers and sleeves

Technically, they’re the same in essence but comparing them would not be ideal as they hold different distinctions.

What are the Applications You Can Have With Industrial Abrasive Wheels?

You can choose to use industrial grinding wheels for a lot of different applications.

Industrial abrasive wheels being used to polish/finish a part or component

But, the most common would be for:

- Cutting or Removing Materials

- Surfacing, Finishing, or Polishing

- Deburring

- Sanding

The most common industries or business sectors that feel the need to use or utilize industrial wheels are:

- Fabrication or Machining Industries

- Wood and Metalworking Sectors

- Shipyard and Shipbuilding Industries

- Marine and Maritime Industries

- And Many More!

How Do You Choose the Industrial Grinding Wheel Manufacturer to Work With?

Out of the vast sea of industrial grinding wheel manufacturers in the market, choosing which one to trust might be tricky.

There are a lot of factors to consider, there’s skill and experience, certifications and licenses, etc.

But, here are some of the best ways on how you can work with the best industrial grinding wheel suppliers and manufacturers:

Check Feedback and Reviews

The best way to find out a company’s skill and expertise would be through client feedback.

See if they have stable and solid client retention rates; assess what other businesses and companies say about them, etc.

This way, you don’t have to guess whether or not their services are effective and efficient.

Assess Company Productivity and Efficiency

You can do this by checking the production capacity and ability they have.

There are certain ways such as reading their stats, asking them, checking up on their prices vs. the market, etc.

You’ll not only find out if they’re the manufacturer you want or not, you’ll also know other relevant information about them.

Contact Previous Clients

Some manufacturers freely display the transactions they’ve had with their clientele – and that’s what you can do to gain knowledge about a particular supplier/manufacturer.

Contact and ask previous clients about the experience they’ve had. You’ll receive nothing but raw and relevant information about them.

These are just some of the most effective ways on how you can choose the best and the right manufacturer for the job.

You can have your own strategies and techniques – but so far, these never failed.

Who Can You Trust to Supply You With the Best Industrial Grinding Wheels?

Here in China, we at Tenyu Tools Co., Ltd. continue to be the best and the most sought after industrial grinding wheel supplier and manufacturer in the market.

Tenyu Tools’ manufacturing process in creating and processing industrial grinding discs

We’ve been the top manufacturer and supplier of industrial grinding wheels for over 15 years. You can work with us if you need diamond grinding wheels, cup grinding wheels, straight wheels, and many more!

A lot of our clients have enjoyed our products and our services, and they never had any problems while working with us.

If you want a piece of the excellence Tenyu Tools Co., Ltd. has to offer, give us a quick email! We’ll respond as fast as we can and we can promise to offer high-quality grinding wheels at a competitive rate!