Cup Grinding Wheel

- Why You Should Choose Tenyu Tools as Your Cup Grinding Wheel Manufacturer

- You can get the wholesale price for the cup grinding wheels you need

- You can purchase different types and kinds of accessories and power tools

- Your products and orders will definitely arrive on time

- Tenyu Tools’ technical experts and engineers have decades of experience

Tenyu Tools: Your PremierCup Grinding Wheel Manufacturers

China is the world’s leader in manufacturing cup grinding wheels. Having over a hundred different companies and businesses, which manufacturer should you work with?

Tenyu Tools Co., Ltd. is the top and the leading manufacturer of cup grinding wheels. We’ve been the best and the most trusted cup grinding wheel supplier for more than a decade by local and international clients.

Tenyu Tools’ Cup Grinding Wheels

If you’re looking for consistent-quality cup grinding wheels, Tenyu Tools is the answer!

Never did our grinding wheels show any defects from their physicality to functionality. In case you find any mishap or inconsistency, we’re just an email away!

Tenyu Tools’ expertise in manufacturing cup grinding wheels will surely impress you. We follow everything through – from the grain, the bond, the shape, and many more!

- You’ll get a natural surface finishing result on concrete, stone, and marble

- You will be able to save up on your costs because cup grinding wheels have longer lives

- Tenyu Tools offers diamond grinding wheels, perfect for steel and metal cutting

- We manufacture our cup grinding wheels either hot or cold pressing

You can find out the benefits you can get from our cup grinding wheels if you choose and purchase our products!

We have clients that aren’t businesses involved in grinding and in cutting. As a matter of fact, if you want to resell, retail, or merchandise our products, we’ll be open to do so!

Having more than 900 clients globally, it’s pretty certain that we’re a cup grinding wheel manufacturer you can absolutely trust and rely on.

Tenyu Tools Co., Ltd Capabilities

Tenyu Tools Co., Ltd. is a company certified in various regions. It doesn’t matter if you are in Asia, Africa, North and South America, Europe – even Australia!

Our cup grinding wheels will absolutely be accepted and be eligible for use there!

In case you’re asking, Tenyu Tools Co., Ltd. is and will be capable of producing and manufacturing hundreds to thousands of tools and accessories daily.

Never hesitate to shoot us an email or to buzz us up if you need cup grinding wheels. Tenyu Tools will be ready and prepared to provide quality cup grinders!

Have you been looking for custom cup grinding wheels? Or do you need pre-made ones? Whatever you need, Tenyu Tools Co,, Ltd. is here for you!

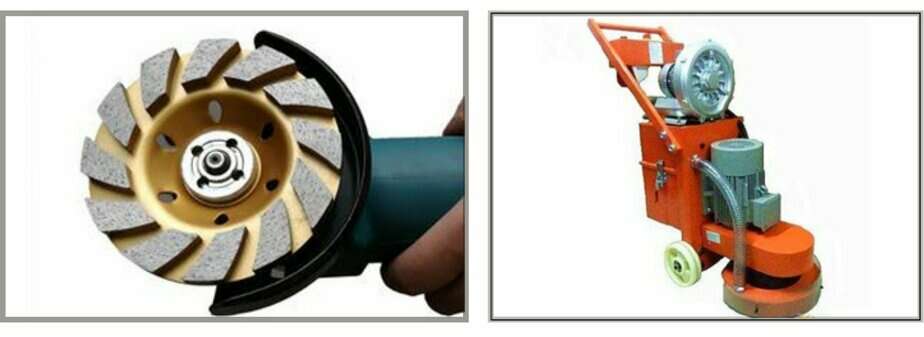

- Manufacturing Machine for Cup Grinding Wheel

- Production Process

- Cup Grinding Wheel Using

Choosing Tenyu Tools’ grinding wheels can get you the following benefits:

Applications of Tenyu Tools’ Cup Grinding Wheels

Think that you don’t need to use cup grinding wheels? Think again!

Cup Grinding Wheel Manufacturers – The Ultimate FAQ Guide

Cup grinding wheels are distinct from any other type of grinding wheel – except for dish wheels, though.

Therefore, you can be sure that the manufacturers of industrial grinding wheels are able to produce cup grinding wheels, as well.

In this article, we’ll teach you everything you need to know about cup grinding wheels. Not only that, we will also help you land on the best cup grinding wheel manufacturer.

What is a Cup Grinding Wheel?

A cup grinding wheel is one of the few types of industrial grinding wheels in the market.

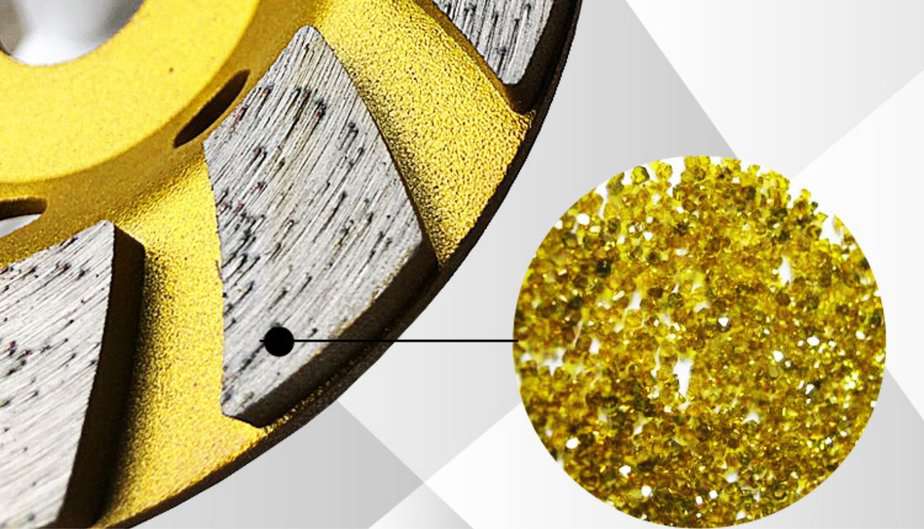

An example of a cup grinding wheel manufactured by Tenyu Tools Co., Ltd.

It’s labeled as a “cup grinding wheel” because of its cup-like shape. Similar to a regular grinding wheel, it’s made up of metal bonding.

Cup Grinding Wheel Uses

What uses do cup grinding wheels have?

Worker using a cup grinding wheel for finishing or surfacing

Several manufacturers are actually innovating on the particular uses of cup grinding wheels.

However, the most common uses you can have for these grinding cup wheels include:

Polishing and Finishing

Cup grinding wheel manufacturers engineer and design their products to be capable of finishing or polishing stone, concrete, or gemstones.

This, though, will depend on the composition of the cup grinding wheel.

Cutting

Cup grinding discs and wheels that have sufficient frits can also take on jobs and work such as:

- Cutting

- Removal of Material

You would have to ask your manufacturer specifically for it, though.

Adhesive and Paint Removal

Lastly, you can choose to use cup grinding wheels to remove paint, adhesive, and other types of material.

All of these are possible; what you have to take note of, though, would be the size of the abrasives.

There are specific cup grinding wheels with specific abrasives to do the job. That’s why you should always keep in mind to ask your particular manufacturer or supplier about the cup grinding wheel you are about to use.

How is a Cup Grinding Wheel Manufactured?

Cup grinding wheel manufacturers can have multiple ways on how they produce their wheels.

Inspection/minimal testing of a grinding cup wheel

But, here’s a quick peek or a summary of how it’s made:

- The grinding body is produced from alloys and other types of metals and steel

- After so, it’s molded into a cup-like shape

- Once it’s been successfully molded, it’s left and is dried out

- Drying can take anywhere between 48 to 72 hours, after which it is heat treated

- Heat treatment is the procedure that binds and integrates all the components together

- Once done the abrasives or the segments are added

- It’s initially inspected to see if there are any defects after the addition of the abrasives or segments

- If it passes, it goes through the finishing procedure where everything is integrated accordingly

- The last and the final inspection takes place, this is also where the labels will be added and will be ready for distribution

NOTE: Several manufacturers have different styles on how they produce their cup grinders. This is just the regular skeletal procedure on how it’s made.

Cup Grinding Wheel for Steel and Metal Applications

Most cup grinding discs are perfect for stone, asphalt, concrete – and other types of masonry.

A grinding cup wheel being used for the surfacing or the polishing of metal or steel

But can you use it for steel and metal? – Yes! You can actually choose to use cup grinders for both ferrous and non-ferrous metals.

You would have to ask and tell the manufacturer about it because you can’t use a cup grinding wheel that is made to be for concrete or stone for steel.

Using a cup grinding wheel made for stone or masonry for metal or steel can cause it to break.

Can You Purchase Custom Cup Grinding Wheels?

Yes, there are cup grinding wheel suppliers in which you can actually manufacture or produce custom wheels.

Worker initially checking the physicality and the balance of a custom made cup grinding disc

In this way, though, the best thing to do is to specify everything from composition, style, size – to shape, the type of abrasive, etc.

Grinding Cup Wheel Prices and Rates

Different grinding cup wheels have different prices.

In fact, there are certain factors to consider in order to arrive at a cost or a price.

There’s the manufacturing process, materials and processes used, features and functionality, and the like.

In addition to that, some grinding cup wheel manufacturers also have different rates depending on the number and the amount of products you order.

For instance, if you order 500 pcs., and the manufacturer gives discounts on orders above 1,000 pcs., then you can expect that the rate you’ll be purchasing it for would be higher and pretty expensive.

You can find and figure out the rates of a certain product by asking your supplier directly for it.

To give you a rough range of how much it would be, disregarding discounts, it’ll be within the range of $2 to $100 per piece.

Are China Cup Grinding Wheel Manufacturers Reliable?

Yes, Chinese grinding cup wheel manufacturers are considered as the best in the market.

Other than the fact that they’re a lot cheaper and more expensive, Chinese manufacturing firms are also known to offer complete services even after the sale.

If you want to work with a cup grinding wheel supplier you can trust and bank on, you can place your complete trust with us here at Tenyu Tools Co., Ltd., the best in the country.

We’ll talk more about that and what we offer in a bit.

Choosing the Best Diamond Grinding Cup Wheel

An example of a newly-manufactured arrow-shape cup grinding wheel Tenyu Tools is offering

When it comes to choosing the most appropriate cup grinding wheel, you need to consider:

What You’ll Grind

The first thing you need to think about is what you need to work on.

Are you going to work on steel or metal? Are you going to cut or grind concrete or stone?

These are important because there are specific grinding wheels you can use for specific objects or materials. Using a different grit and a different grinder can actually break your grinding wheel.

The Parts of the Grinding Wheel

In case you’re not aware, cup grinding wheels have three (3) parts and components, which is the bond, the abrasives, and the additives.

Before purchasing a particular grinding wheel, it is imperative that you know the parts they have.

For instance, you need to know if the bonds are really going to be able to cater to your needs. Knowing this can actually make or break the grinding wheel you’re going to use.

Grinding Process You’ll Do and Perform

Lastly, you need to take note of the processes you will do and perform with your wheel.

Would you need it for cutting? Polishing? Finishing – or surfacing? You need to finalize and to decide on which processes you’re going to do.

This will help you maintain the quality of your cup grinding wheel.

Knowing these is relevant in terms of ensuring the quality and the overall performance of your cup grinding wheel.

How Do Manufacturers Dress Cup Grinding Wheels?

Dressing a cup grinding wheel is similar to repairing it.

Part of the dressing procedure or process of grinding cup wheels and discs

In the event that you need to dress it fully, you can try and imitate the following steps:

- Identify the correct dressing tool for your grinding wheel

- Turn the grinding machine one (ensure that the cooling pump is deactivated)

- With the grinding wheel at its full RPM, use pressure that is light-to-medium to the abrasive or the surface of the cup grinding wheel

- You’ll know when to stop when the wheel halts from rotating or from spinning

- Keep on doing steps 3 and 4 until the entire grinding cup wheel feels like it’s pulling it away from you

Akin to how various manufacturers produce and manufacture cup grinding wheels, other manufacturers may have different techniques and strategies in dressing grinding wheels.

There’s no right or wrong way to do so – what you need to look at and to take note of would be the effectiveness and the efficiency of the procedure.

Would their process really enhance or develop my grinding cup wheels? Would they be effective in getting back the sharpness and the precision of my cup grinding wheel?

What is a Type 5 Grinding Wheel?

Type 5 cup grinding wheel is the kind of wheel you need to utilize for grinding certain materials that need rough and hard operations.

What a Type 5 abrasive grinding cup wheel looks like

You need to use both type 5 and type 7 grinding wheels for it. Moreover, both types 5 and 7 wheels are known to be “recessed” grinding wheels.

The most common objects and materials you can use Type 5 cup grinding wheels for include:

- Nickel

- Steel

- Iron

- Stainless Steel

- Removal of Material (Light to Heavy)

The Best Cup Grinding Wheel Manufacturer in China?

Here in the country, no other grinding cup wheel supplier trusted but us at Tenyu Tools Co., Ltd.

Tenyu Tools’ plant in the manufacturing or the production of cup grinding wheels

For more than 15 years, we’ve provided superior grinding wheels to our clients. Whether they need pre-made cup grinding wheels or custom made wheels, we’re able to deliver!

You’ll never find a cup grinding wheel manufacturer as dominant and as serious as us! You can send us a quick email of the orders and the grinding cup wheels you need and we can surely deliver!

MoQ of Tenyu Tools Co., Ltd.

Unlike other cup grinding wheel manufacturers out in the market, Tenyu Tools Co., Ltd. will never require you to order more than 100 pcs.

The Minimum Order Quantity (MoQ) that we have here at Tenyu Tools Co., Ltd. is only at 100 pcs.

You can have customized cup grinding discs or pre-made wheels!

Why Tenyu Tools is the One You Should Work With

Workshop of the manufacturing plant of where our grinding cup wheels are manufactured

A lot of businesses and companies choose to work with us here at Tenyu Tools because:

- We can deliver all of your orders within 15 to 21 days at the maximum

- We have the best and the most reliable Research & Development (R&D) Team

- We have a one (1)-year warranty for all the orders you have

- You can count on Tenyu Tools’ aftersales department and team

- The packaging and the shipping procedure we offer is topnotch

- And many more!

Tenyu Tools Co., Ltd. would never be considered and marked as the best cup grinding wheel manufacturer for more than a decade if it weren’t for the excellent services and products we have.

Online Workshop and Showroom

Apart from all those details, we here at Tenyu Tools also have an online workshop and showroom to offer you.

This is where you can have a view of our manufacturing plant, as well as the manufacturing procedure that we have for our grinding cup wheels.

Transparency-wise, you will be able to know our full capacity even before you visit us.

You can also freely ask our previous clients about the overall performance we have as a grinding cup wheel manufacturer!

Features of Tenyu Tools’ Cup Grinding Wheels

Some of the most notable features that our grinding cup wheels have include:

Our cup grinding wheels entering the first few phases of the manufacturing procedure

- Super turbo cup grinding wheels for cutting of stone, asphalt, and concrete

- The wave row segments of our cup grinding wheels are brazed for faster and smoother grinding

- High levels of diamond concentration for diamond cup grinding wheels

- Configuration of turbo segment for softer and faster removal of material

- Applicable for wet and dry grinding

- Long-lasting and durable

- And many more!

What’s even more special is that we can follow sketches and drawings of the specific cup grinding wheel you need!

Through our Research & Development (R&D) team, we can accurately and precisely abide by the design, kind, and the type of grinding cup wheel you need!

In case you’re growing more and more curious as to how our cup grinding wheels perform, don’t hesitate to give us a quick shout!

You can contact us via our email address or via WeChat! All of which are available on our website.

Work with the cup grinding wheel manufacturer you can trust and you can bank on.

We guarantee that you will never have any problems and troubles in working with us!