Cutting Wheel Manufacturer

- Choosing Tenyu Tools as Your Cutting Wheel Manufacturer

- You can get cold or hot-pressed cutting wheels from us

- Tenyu Tools can create and manufacture the exact requirements you need

- You’ll be able to use our cutting wheels in a wide variety of applications

- You can see all the certifications and licenses we have as a manufacturer

- Wherever you are, you can get your orders in less than 21 days!

Why Cutting wheels have been one of the most popular products Tenyu Tools has?

Our distinct make and sophisticated style leaves all other competitors yearning for our procedures.

Tenyu Tools Co., Ltd. is the top name in Chinese cutting wheel manufacturing. Whether you need brazing grinding and cutting wheels, sintered, or electroplated, you can count on us!

Tenyu Tools’ Cutting Wheels

The best thing about working with us is that you can customize the cutting wheels you need.

A worker finalizing the creation of a grinding/cutting wheel

If you need a 5-inch cutting wheel with specific alterations – or if you’re looking for a 7-inch diamond grinding wheel, you’ve come to the right place.

Tenyu Tools, being the best cutting wheel manufacturer, will always help you achieve what you need.

You can purchase wholesale or retail, and you will be able to get the right kind and type of functionality you want for your grinding wheels.

Why Work With Tenyu Tools for Your Cutting Wheels?

The cutting wheels we offer are all made with accuracy and precision

Here are some of the reasons why you should choose to work with us for manufacturing your cutting wheels:

- All our cutting wheels last 3 to 5 times longer than regular cutting wheels

- We perform surface finishing naturally

- Our cutting wheels can accommodate the most aggressive removal or subtraction

- We offer a wide variety of cutting and grinding wheels for your needs

- Before delivery, all our cutting wheels are evaluated and inspected!

Applications of Tenyu Tools’ Cutting Wheels

They’re made for cutting rock, concrete, and asphalt. So, if your business involves this kind of activity, our cutting discs will be sufficient.

Cutting wheel working on a piece of marble

In addition to that, we also work with distributors, retailers, and merchandisers; we’re open for business with an entity that is interested in our product.

Tenyu Tools Co., Ltd. is a world-renowned company in manufacturing cutting wheels. We have tens of partners from all around the globe!

Contact Us Now!

Having more than 970 regular clients worldwide, there’s no doubt that we’ll be able to meet whatever your expectations are!

Amassing more than a decade of experience in the industry, there will never be a shortage of quality in all our products! You can trust us to help you with every tool you need!

Get to work with the most trusted and the most relied on cutting wheel manufacturer in the industry!

Reach out to us via our email or via our WhatsApp and receive world-class quality cutting wheels at considerable rates and prices!

- Manufacturing Machine for Cutting Wheel

- Production Process

Cutting Wheel Manufacturer – The Supreme FAQ Guide

The demand for grinding and cutting wheels has excelled in the past couple of years. That led to the birth of a myriad of cutting wheel manufacturers, too.

That oversaturated the market – and it made choosing a manufacturer more challenging and difficult.

In this guide, we’ll discuss everything you need to know about cutting wheels. As a bonus, you’ll also learn how you can choose and work with a reliable cutting wheel supplier! So, stick around!

What is an Industrial Cutting Wheel?

A cutting wheel is basically a tool that you use to cut a material or a workpiece.

An industrial cutting wheel, slicing through steel

Oftentimes, you use an industrial cutting wheel to cut metals, as well as other alloys.

Composition of a Cutting Wheel

Since the discovery of abrasives being more effective and efficient, a lot of cutting wheel manufacturers decided on this.

General composition of a cutting/grinding wheel

Therefore, most, if not all cutting wheels are made from an abrasive disc that is solid in nature. They’re expected to cut through thick pieces and chunks of metal, anyway.

However, there are also other types of cutting wheels, we’ll discuss them below.

Difference Between Cutting Wheel and Grinding Wheel

While many experts and professionals treat them the same, they have certain distinctions.

You can use cutting wheels to grind, and grinding wheels to cut – no question on that. However, when it comes to the physicality of the material, you’ll notice a ton of differences.

Cutting wheels often thinner than grinding wheel; this basically means that a cutting wheel will be able to cut faster and cleaner than a grinding wheel.

In addition to that, since grinding would require you to put pressure on one face, your cutting wheels might break if you apply even a thin slice of pressure.

Who is the Most Popular Cutting Wheel Manufacturers?

There aren’t a lot of well-known manufacturers of cutting discs; this was due to the fact that many newer companies outworked previous ones.

You can search the market for a ton of cutting wheel manufacturers and find that most of them offer similar products.

So, popularity isn’t really necessary in the tools and accessories industry. What you need is to perform research, and we’ll teach you that in a later part of this guide.

What is a 3-Inch Cut Off Wheel?

It’s a type of grinding/cut off the wheel that’s 3-inches in diameter.

A sample of how a 3-inch cutting wheel looks like

This small tool is something you can use in various applications, including:

- Cutting a slab of 2×2 wood

- Thin metal sheets

- Addition of details, grooves, and creases

- Polishing of workpieces

- Removal of scratches

What is a 7-Inch Cut Off Wheel?

Generally, 7-inch cutting wheels are thinner and slicker than other sizes.

7-inch cutting wheel, which you can use for cutting concrete, marbles, and another masonry

This is so you the subtraction of content or material is slower and fewer, helping you with more precise and more accurate cuts and slices.

The most common uses of 7-inch cutting discs include:

- Aluminum

- Fiberglass

- Glass

- Sheet metal

- Mild steel

- Stainless steel

What Can a Cutting Disc Cut?

Cutting discs or wheels are versatile tools that you can use for cutting or removing materials in the likes of metals, concretes, stones, aluminum, alloys, woods, glasses, etc.

The wide range of these materials and objects makes cutting wheels the perfect solution to your problems.

How Long Can a Cutting Disc Last?

If we take it on a regular scale, one cutting wheel or the disc can last up to a total of three (3) years.

Cutting wheels that are already worn out

That figure, of course, is still dependent on the frequency of usage, activity, as well as the type of material being cut.

Three (3) years is just the date on most cutting wheels on their label.

What’s the Best Cutting Wheel for Steel and Metal?

Since metal and steel are both categorized in the ferrous group, the best cut off wheel to use is Aluminum Oxide abrasive grain.

This kind of cut off wheel is the most common in the charts of cutting wheels. You’ll also find that it’s compatible with any type of grit range.

What are the Different Cutting Disc Types Available?

We already know that most cutting wheels are made from solid abrasives. But are there other types of it that cutting wheel manufacturers produce?

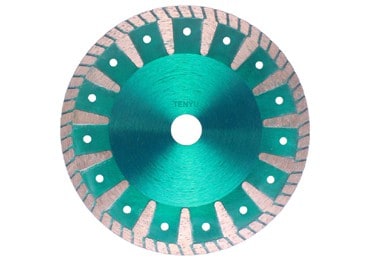

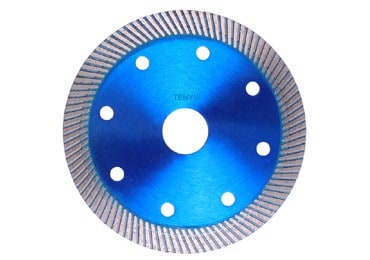

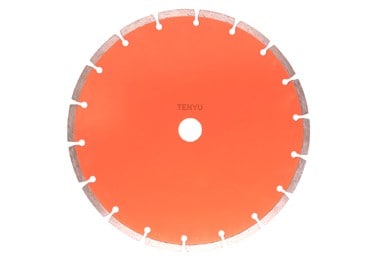

An image of a segmented grinding wheel we offer at Tenyu Tools

Apart from abrasive discs and wheels, there are:

- Large Diameter Grinding Wheels

- Grinding Dish Wheels

- Segmented Grinding Wheels

- Cutting Face Grinding Wheels

- Straight Grinding Wheels

- Grinding Cup Wheels

Each of these circular cutters has their own purposes.

Although their effects aren’t that impacting, using a specific type of cutting wheel for a particular project will make your life easier.

Standard Sizes for Cutting Wheels

There is not a single size that standardizes cutting wheels and discs. In fact, there’s a specific range that’s considered as “the most popular.”

Samples of the standard cutting wheel sizes available in the market

The range of the standard sizes for cutting wheels is between two (2) to sixteen (16) inches in the diameter of the wheel.

Anything that falls between that range is considered “standard.”

Cutting Wheel Manufacturing Process

The process of manufacturing of cutting wheels isn’t something difficult.

The production process of cutting wheels and discs

In fact, the process is similar to how other tools are made.

- The process starts off by collecting the raw materials needed for the process.

- These are then mixed, with specific quantities of the bond materials, abrasives, as well as additives.

- Once they’re mixed, the consistency would be thicker and harder. This is when molding is done.

- The mixed ingredients are molded into shape, depending on the demands of the client.

- The bore or the hole in the middle is pressed and is formed

- Then, the disc or the wheel is formed using a hydraulic press or any other type of pressure.

- After it’s removed from the press, it’s going to be dried. This also is the time for the final shaping of the wheel.

- The disc is then sent to a kiln or a furnace for heat treatment.

- After being cooled down, the discs are finished, it may involve:

- Casting or reaming of the arbor holes

- Creation of contours

- Balancing of the wheel’s face

This is the regular structure of how a cutting wheel is manufactured. It’s imperative to note that some suppliers and companies might have their “specialty” when it comes to the manufacturing process.

Can You Use Cutting Discs for Drills?

Yes, you can actually attach your cutting wheel to a drill.

Cutting disc attached to a drill, slicing through tile or marble

However, you need to note that the boring hole or the hole in the middle of the disc will fit the drill.

This may include the nuts and bolts, as well as other locking mechanisms that might be involved in the process.

Can You Use Cut Off Wheels in a Die Grinder?

Everyone would think of it as one – but die grinders and cutting tools aren’t actually the same.

Image of a die grinder

As a matter of fact, a lot of people think that you can use it alternatingly. However, it can impose a ton of danger and hazard with the worker and the material you’re working on.

The reason is that most die grinders don’t have an appropriate mounting tool. This can make it hard for a wheel or a disc to maintain its movement.

In addition to that, die grinders also don’t have wheel guards, making it unsafe.

How Much Does a Cutting Disc Cost?

The price of a cutting wheel will vary from manufacturer to manufacturer. There can’t be a regular or a median price that would dictate the pricing of suppliers.

You’ll find cutting discs that are as cheap as $0.20, while there can be others that can go as high as $100.

Because of the make, the manufacturer, the production process, and the machines and equipment used – different cutting wheel manufacturers price them differently.

For you to be able to finalize the price and the rate, the best thing to do is to contact the manufacturer or the supplier of your choice.

Ask them if you can purchase cutting wheels wholesale or if they offer discounts if you bulk-buy.

Minimum Order of Cutting Wheels

This, again, will depend on the manufacturer of your choice.

Some stores and manufacturers require a minimum order quantity for particular products. However, there are some manufacturers that don’t.

How Can I Choose the Best Cut Off Wheel?

Why do you need to choose the best and the most appropriate cutting wheel? Because of the following reasons:

- You’ll be able to cut or remove more material, just by using one (1) cut off wheel

- You can save time, money, and effort in your operations

- You’ll be able to minimize and reduce the risk of your cutting wheel’s wear

- You can experience better and easier post-processing

Here are some of the things you can do to make sure that you purchase the right cutting wheel:

Hardness Test

The first thing you need to know is the hardness of the cutting disc.

There are manufacturers that have prepared charts for the hardness of the cutting wheels they have.

If not, some manufacturers will be open to assist you in testing it out for yourself.

Wear Sample

More often than not, the best and the most appropriate cutting wheel will be less worn after cutting a material.

An incorrect one would be used and worn-out more.

Material You’re Working On

Lastly, if you know the type of material you’ll use a cutting wheel for, you can just tell your manufacturer about it.

There are a lot of manufacturers open to these types of inquiries. Don’t be afraid or be too shy to ask for it.

You can contact the specific manufacturer you have eyes on and ask for assistance.

These are some of the things you can take note of to make sure that you’ll be able to purchase the correct type and kind of cutting wheel.

Tips in Working With the Best Cutting Wheel Manufacturer

What should I look for in a cutting wheel manufacturer?

This is one of the most thrown and asked questions in the industry. If you want to work with the best cutting wheel supplier, you need to ask yourself the following questions:

- What type of manufacturer am I looking for?

- Is the manufacturer I’m eyeing certified?

- What are most of their reviews about? Positive or negative?

- How do they manufacture their cutting wheels?

These questions will basically allow you to find out more about a manufacturer.

In addition to that, you’ll easily be able to tell if a manufacturer is worth it to work with or not.

Who’s the Best Cut Off Wheel Manufacturer in China?

Across the country, no other cutting disc manufacturer is trusted but us here at Tenyu Tools Co., Ltd.

Some of the tools and accessories Tenyu Tools is offering

We’ve been supplying power tools and accessories to our clients for over 15 years! In that timeframe, we never received any kind of negative feedback pertaining to our results.

We’re a manufacturer you can absolutely work with if you need cutting wheels, whatever type, size, and shape you need!

Why Choose Tenyu Tools as Your Cutting Wheel Manufacturer?

A lot of our clients trust us because:

- We’re a certified manufacturer of power tools and accessories

- We’ve been able to produce thousands of inserts and tools on a daily basis for years

- We can deliver all of the parts you need in 15 to 20 days

- You can count on us whatever country you’re in

- We can manufacture the specific cutting wheel or disc you need

Send us an email or a message in any of the contact channels we have. For all your cutting wheel needs, you can trust and count on us here at Tenyu Tools!