Industrial Circular Saw Blade

- Your Best Industrial Saw Blade Manufacturer

- Tenyu Tools Co., Ltd. meets industry standards in manufacturing industrial saw blades

- You’ll experience utmost convenience in order – get it in 2 to 3 weeks!

- You’ll see zero defects on our saw blades; we assess all before delivery

- You can get lifetime aftersales support on all products you purchase from us

- You can ask us to customize the industrial circular saw blades you require

- You can count on Tenyu Tools to offer all types of industrial circular saw blades in the market.

- Being the most trusted industrial saw blades manufacturer in China for over 15 years, you’ll never regret your decision.

Tenyu Tools’ Industrial Circular Saw Blades Manufacturer

Tenyu Tools Co., Ltd. can manufacture a wide variety of power tools and accessories. You can ask us to manufacture specific circular wood cutting saw blades, metal cutting blades, masonry saw blades and many more!

The industrial circular saw blades that we’re offering have all been certified in various regions.

Whether you’re in Asia, North America, Europe, Australia, or Africa – it’s accepted!

You can get different types and kinds of industrial circular saw blades. Tenyu Tools are offering saw blades for:

- Wood

- Concrete or Masonry

- Steel or Metal

- Grass

- Plastics

- Other Types of Materials

You’ll experience no shortage of the highest quality of blades from the best industrial saw blade manufacturer in the country.

Advantages of Choosing Our Industrial Cutting Saw Blades

You can gain a ton of advantages in choosing Tenyu Tools’ industrial circular saw blades. Some of which include:

- All our industrial circular saw blades aren’t only made for cutting

- We completely polish and finish all the circular blades we offer

- Tenyu Tools is equipped with the best inspection team to evaluate the saw blades

- You can contact us even if you’re a distributor or a merchandiser

- We perform testing on all the industrial saw blades we manufacture

Applications of Tenyu Tools’ Industrial Circular Saw Blades

Tenyu Tools, being the best industrial saw blade manufacturer, is not only limited to cutting.

Our saw blades can be embedded and installed to other cutting machines like lathes, slicers, etc.

You can also utilize the saw blades we’re offering for other purposes, too including:

- Combat (Weaponry)

- Kitchen or for Cooking

- Furniture-Making

The flexibility and the versatility of our industrial circular saw blade will make you want to work with us again!

Why Choose Tenyu Tools?

Apart from the fact that we’re the best, Tenyu Tools Co., Ltd. is also the manufacturer you can trust to produce a prolific amount of industrial circular saw blades.

We have a catalog of the products we’re offering, complete with a product inventory as well as a quality assurance (QA) team to ensure the quality of our products.

Contact us and get the best and the highest quality of industrial circular saw blades for a reasonable price!

You can get a free quotation for the orders and products you need, too!

Send inquiry now! we can reply in 24hours!

- Manufacturing Machine for Industrial Circular Saw Blade

Industrial Circular Saw Blade – The Ultimate FAQ Guide

The flexibility and versatility of industrial circular saw blades always go overlooked. A lot of businesses need it not only because of its cutting ability, but also because of what it is.

Do you need an industrial saw cutter? What is it anyway? For the benefit of people who are yet to fully understand it, this guide is for you!

Today, we’ll not only talk about what industrial circular saw blades are, we’ll also be discussing other important factors to it as well.

By the end of this guide, you’ll already know who you’ll go to as your industrial saw blade supplier.

Do Industrial Circular Saw Blades Make Good Knives?

Yes, especially if they’re new. If they’re old and worn-out, though, you can recycle the metal body of the circular saw to make it a knife.

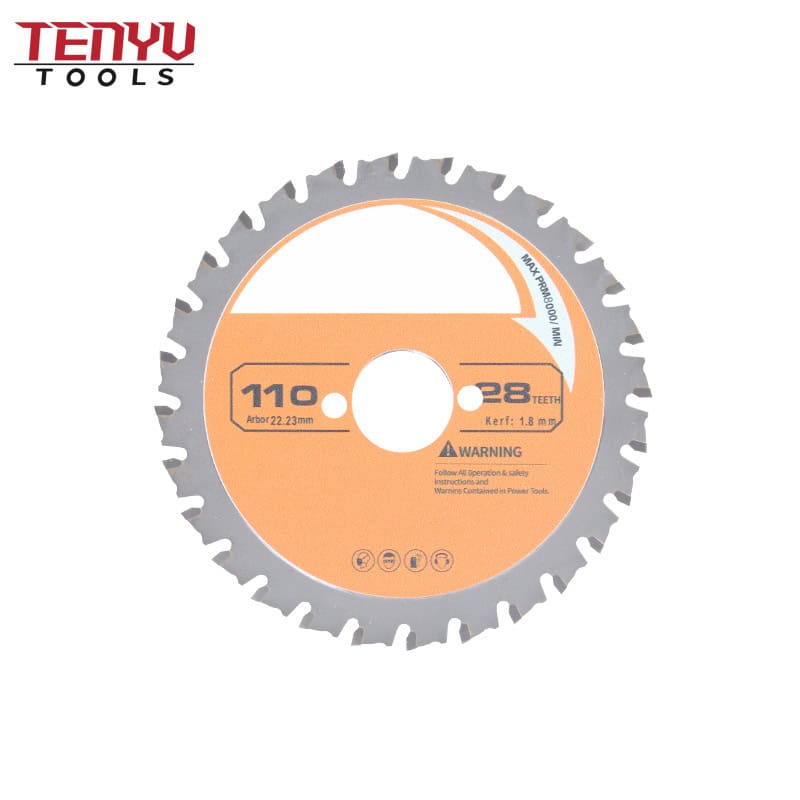

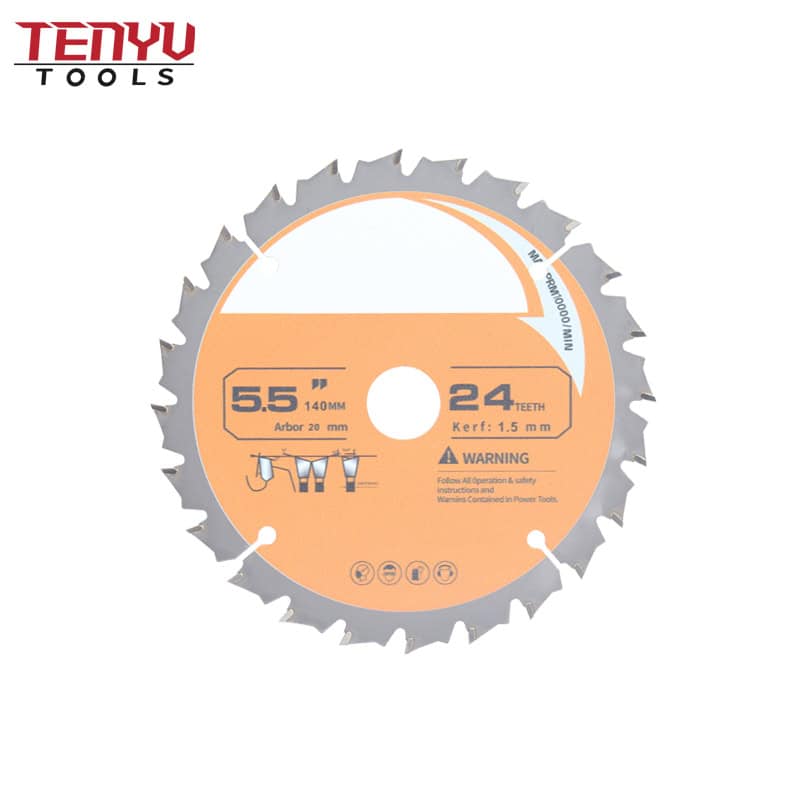

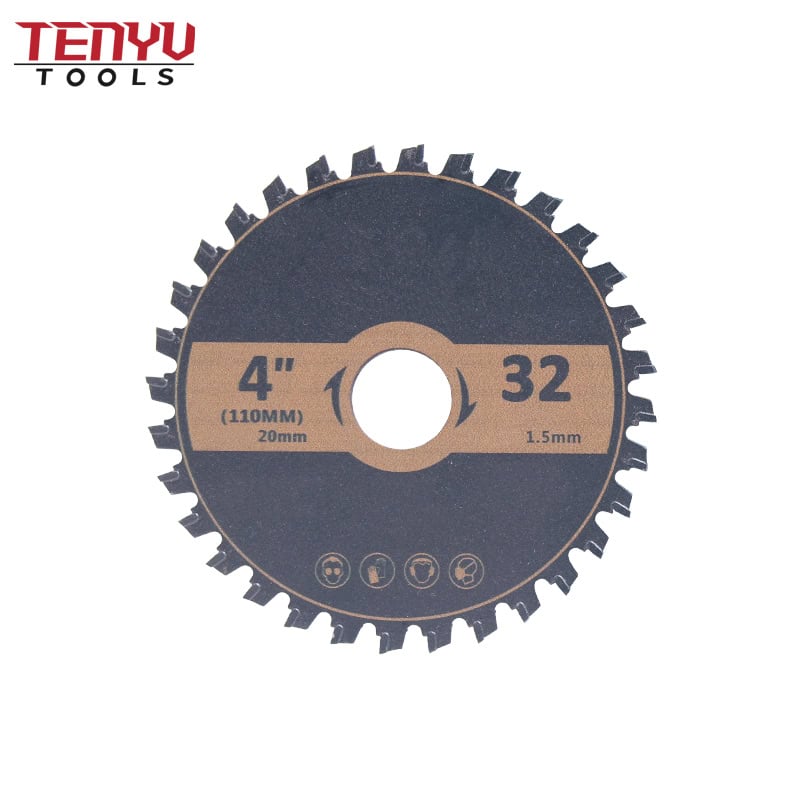

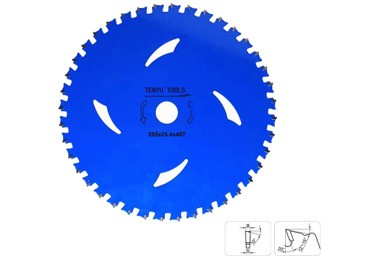

Versatile collection of Tenyu Tools’ industrial circular saw blades

The type of knife you’ll be able to create would depend on the material that the blade has been made from.

Are Circular Saw Blades Hardened Steel?

If you mean the body, then no, it’s not hardened steel. More often than not, the bodies of these circular blades are made from mild steel, which is something you can’t harden.

Bodies of circular saw blades are mild steel, which cannot be hardened

The teeth, though, are constructed and coated with carbide; that’s what makes it sharper and more effective.

What Type of Steel are Circular Saw Blades Made Of?

Most of the time, the steel of the saw blades (the body) is made of high-speed steel or HSS. An alternative would be carbon steel.

This will depend on the material it’ll be made to cut.

There also are TCT or tungsten carbide tipped saws that have tungsten carbide brazed at its teeth. It’s designed to give you smoother cuts at a faster rate.

How Do I Attach or Change an Industrial Blade to My Saw?

Attaching the circular saw blade might seem easy and simple, but it can be dumbfounding, too.

Here’s how you can attach your industrial circular saw cutter to your handle:

- Unplug your saw from where it’s connected

- Notice if it has a spindle lock. The spindle lock is a security function that prevents the continuous spinning while the blade bolt is loosened

- If it does, press the spindle lock while turning the blade or manually screwing it with your hands. Do this until you feel the engagement of the blade or when it stops turning

- Once done, loosen it by loosening or unscrewing the bolt. Turn it clockwise if the blade is on the left, and counterclockwise if it’s on the right

- Remove the screw and the washer (if there is a washer)

- Push the lower blade guard upwards so you could release the blade

- Take your new circular saw blade and match the arrows that your blade has to the arrows of the blade guard

- Screw the bolt back in again and reengage the washer (if there is one)

- Make sure that the screws are tight enough so that it doesn’t wiggle or vibrate when it’s turned on

What are the Parts of an Industrial Circular Saw Blade?

Identifying the parts of an industrial saw blade is not rocket science. In fact, we’ll be able to distinguish them easily.

Image of a saw blade with all the parts complete

Here are the parts of a circular saw cuter:

- Arbor

- Tooth/Teeth

- Tip

- Gullet

- Expansion Slot (if there’s any)

Are MIter Saw Blades and Circular Saw Blades the Same?

Yes, a miter is a machine where you’d have to install a circular saw blade.

Circular Miter saw blade that is cutting on hardwood

Therefore, the miter and the circular saw blade are the same. They’re both circular in shape and they carry the same functionality.

What is the Process of Hardening an Industrial Saw Blade?

The procedure of hardening an industrial circular saw blade is called heat treatment.

Process of heat treatment to solidify metal or steel

It’s a process where you heat the blade in temperatures between 860 and 1,100 degrees Celsius, depending on the material being treated.

You’ll be able to know it because the material would turn orange – or molten. When it cools, it’ll be harder and tougher.

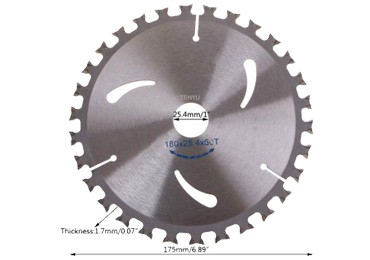

What Does Different Tooth Counts for Industrial Circular Saw Blades Mean?

Not all circular saw blades are the same. In fact, they differ a lot, especially when it comes to the tooth count.

Generally, you could expect that circular blades that have more teeth will be able to cut smoother.

Those that have fewer teeth, on the other hand, will be able to cut faster but with less finesse.

To cite an example, imagine a blade that you’d use for cutting wood and/or lumber. Oftentimes, that type of blade would have 18 to 24 teeth, which is specifically meant to cut or remove material or wood faster.

Blades that are made and meant to cut aluminum, on the other hand, would have about 30 to 40 teeth, making the procedure a bit slower but with more accuracy and precision.

How Long Do Saw Blades Last?

The life expectancy of saw blades would usually depend on usage.

Image of a damaged or a broken circular saw blade

Since it’s a material that would be involved in a lot of work, it’s going to be worn out if it’s used more often.

On a regular situation, a circular saw blade that is properly maintained would last a long time. You can expect it to be able to perform about 850 to 1,050 cuts.

In addition to that, maintained industrial circular saw blades can also be sharpened between 30 and 40 times.

Blades that aren’t properly taken care of could have a huge chance of being less durable.

Industrial vs. Standard Saw Blades: Which One Should You Buy?

In a much simpler comparison, a standard saw blade is a typical saw blade you use to cut wood or any composite of wood.

Industrial saw blades, on the other hand, are used for other materials such as:

- Marble and/or Concrete

- Steel and/or Metal

- Glass and/or Fiber

- Plastics and PVCs

If your business involves the making or the creating of furniture, going for standard saw blades would be your best bet. Although there are industrial saw blades you can bank and count on too.

But, if you’re going to perform a lot of steel or metal cutting, industrial circular saw blades would be what you need.

What Types of Wood Can You Cut With Circular Saw Blades?

You’ll be able to cut and work on a wide variety of woods in using saw blades.

A thin plywood being cut using a standard circular saw blade

From regular softwoods, plywood, cedar, hardwood, to pine, cedar, and ash – you can utilize industrial circular saw blades effectively and efficiently.

What are the Most Common Defects of Industrial Circular Saw Blades?

If you’re new to the tools industry, you might only know warping as the only damage. But, there actually are a lot more.

The most common defects and failures your industrial saw blades can experience include:

- Light to heavy wear on the tips, corners, and sides of the teeth

- Broken or chipped out teeth

- Gullets of teeth loaded with chips

- Light to heavy wear on the blade

- Cracking or chipping in the gullets

- Blade scoring

- Blade’s back edge – extreme wear

- Broken band at the butt weld or in the body of the blade

Most of these have the same reasons. That’s why you need to make sure that you’re religiously abiding by the proper ways on how you should take care of your circular cutting blades.

What is the Most Popular Industrial Saw Blade Size?

The most popular size of industrial circular saw blade falls at 7-1/4 inches. This is because of the fact that its size is median – not too large and not too small.

An example of a 7” industrial circular saw blade, which is the most common size

In addition to that, you can be certain that a 7-1/4-inch industrial circular saw blade would be able to cut or slice through six (6) or more inches of material in one single pass.

If you’re a beginner and you’re confused at what size you need, going with a 7-1/4-inch saw blade would be the best and the cleanest option you have.

Industrial Circular Saw Blade Qualities You Should Look For?

Choosing an industrial circular saw blade you should purchase is a difficult task.

The quality and the effectiveness of the project would rely on the specific type and kind of saw blade that you’ll purchase.

In choosing, you have to take note of the following variables to ensure that it’s exactly what you need:

Teeth Configuration

You can choose from the following teeth configurations:

- Flat Top (FT)

- Combination Tooth (CT)

- Triple Chip Grind (TCG)

- High Alternate Top Bevel (Hi-ATB)

- Alternative Top Bevel (ATB)

All of them have their own specialties, and it’s going to be important for you to figure those out.

Hook of the Teeth

You can choose from two (2) types of hook:

- Negative hook angle – when the blade teeth are opposite to the rotational axis of the blade

- Positive hook angle – when the blade teeth are all leaning forward

More positive angle means more aggressive cutting.

Teeth Count

As mentioned above, you need to take note of the quality you want to achieve.

Should you want faster results, you’d want to choose blade that have fewer teeth. If you want smoother and cleaner outputs, you want a blade with more teeth.

Width of the Kerf

The kerf is the opening that the saw blade is able to cut in the material.

You can choose from a full-kerf blade, which has a thickness of 1/8 of an inch; or a thin-kerf blade, which has a thickness about 3/32 inches – or below 1/8.

In choosing an industrial circular saw blade you’ll purchase, try to find these out. You’ll be surprised at how effective your operations will be if these are all on point.

Who are the Top Industrial Saw Blades Manufacturers?

Out in the market, you’ll encounter tons of suppliers and manufacturers of circular industrial saw blades.

There’s DEWALT, PILANA, AKE, Dimar, and others. Those we mentioned are the most popular and considered as top-tier industrial saw blade manufacturers.

What this means is that they’ll never fail you in terms of quality; but you should expect to spend some money as well.

Which Industrial Saw Blade Manufacturer Should You Work With?

Factory of Tenyu Tools in China, the best Industrial Saw Blade Manufacturer

A manufacturer that’s not famous does not automatically mean they don’t perform. Here in China, Tenyu Tools Co., Ltd. has been the go-to manufacturer of industrial saw blades.

For more than 15 years, we’ve been developing and innovating on different tools for all types and kinds of work.

We’re an experienced and a certified industrial saw blade manufacturer that can give you the exact type of saw blade you need!

You can view our online show workshop, showcasing the masterpiece we have built for the past couple of decades.

Tenyu Tools can give you power and hardware tools and accessories the way you like it!

Why You Should Choose Tenyu Tools as Your Industrial Saw Blade Manufacturer?

- You can be one of our 950+ clients worldwide who trust us!

- We have highly-experienced and highly- educated engineers

- You’ll be able to get your products within 2 to 3 weeks from the date of order!

- We don’t just offer saw blades – you can check out our other products too!

Contact Tenyu Tools Now!

If you feel like there’s no other company you can trust when it comes to saw blades, think again.

Tenyu Tools Co., Ltd. is just an email away! Send in your requests and we’ll work with you to achieve it!

We’ll also give you a free estimate of all the products you need! All you need to do is to reach out to us!