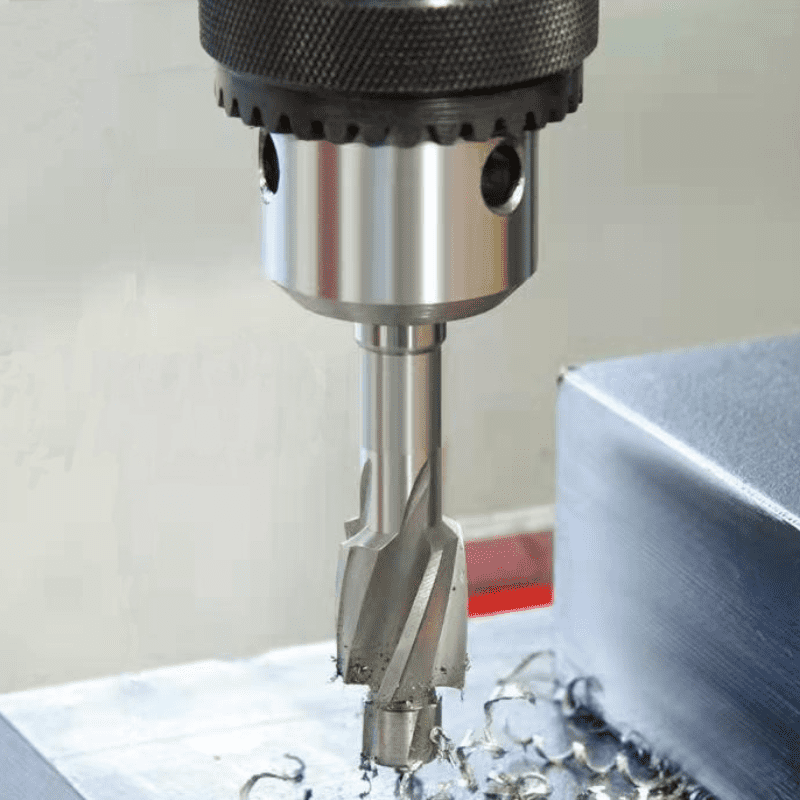

Counterbore Drill Bit

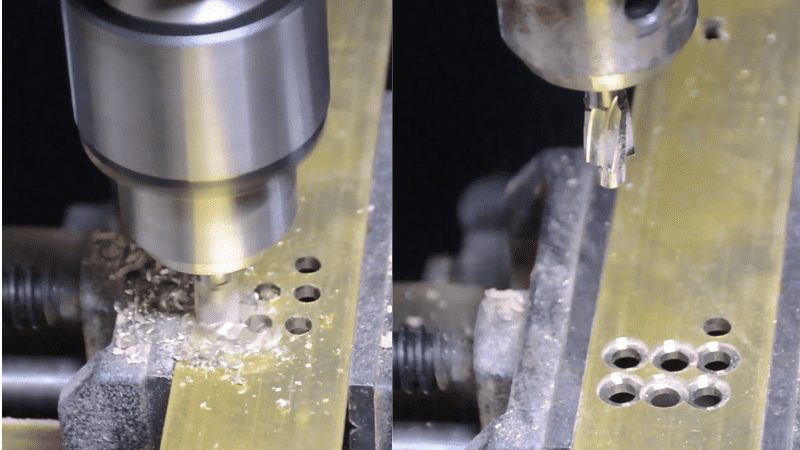

A counterbore drill bit is a specialized type of drill bit that is used to create both the hole for the body of the fastener and the larger-sized cavity for its head, all at the same time.

Tenyu Counterbore Drill Bit Video

Why Tenyu

Counterbore Drill Bit

Unrelenting Customer Support We never get tired of giving our clients the support and assistance they need! Do you have a question before the sale? Do you yearn to learn more about our lineup of taper length drill bits and can’t decide which one to go with? Contact us and we’ll answer all your questions and concerns!

Expertise and Professionalism Our employees all have a combined experience amounting to 70 years in blacksmithing and in toolmaking. We’re sure that we’ll be able to produce the exact taper length drill bits you need for your business!

Progressiveness and Flexibility Tenyu Tools Co., Ltd. breeds on new products and we you will never have any trouble if you want to innovate or be different compared to other suppliers and manufacturers in the industry. In terms of creativity, you can absolutely count on us!

Swift and Fast Delivery With Tenyu Tools Co., Ltd., you’ll never have a problem when it comes to delivery. We’re known for lightning-speed delivery. Thanks to our partnerships with some of the country’s top courier, as well as freight and cargo services, we can get you the orders in less than two (2) months!

7Pcs M3.2-M12.4 HSS Counterbore Pilot Slotting Milling Cutter Set for Copper Aluminum Cast Iron

5pcs HSS M3-M8 4 Flutes Counterbore End Mills Set for Copper Aluminum Steel Cast Iron

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

Cobalt Drill Bit: The Ultimate FAQ Guide

What is a Counterbore Drill Bit?

The counterbore drill bit is designed with a counterbore cutting edge and a fluted drill bit tip. The counterbore cutting edge extends around the circumference of the drill bit just below where the flutes begin.

This design helps to prevent the fastener from being pulled through the counterbored hole. The most common type of fastener used in conjuction with a counterbore drill bit is a flat-bottomed screw, such as a round head or pan head screw. Counterbore drill bits are available in a variety of sizes.

What is Counterbore Drill Bits

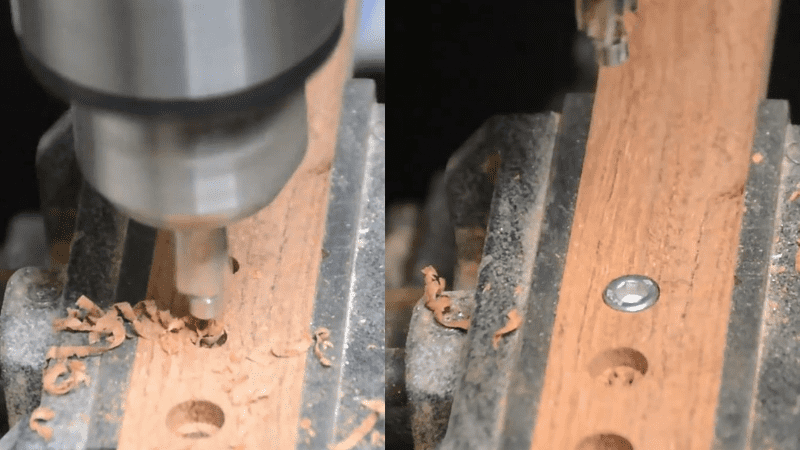

What are Counterbore Bits Used for?

A counterbore is a type of drill bit that is used to create a counterbored hole. A counterbored hole is one that has been enlarged at the top so that it is slightly wider than the body of the screw or fastener that will be used in it.

This type of hole is often used when it is important for the head of the screw or fastener to sit flush with the surface of the material. In order to create a counterbored hole, a counterbore drill bit is used.

This type of drill bit has a cutting edge that is flared out at the tip, which helps to create the widened opening at the top of the hole. Once the hole has been drilled, a socket-head screw can then be inserted and secured in place with a lock washer, ensuring a tight and secure assembly.

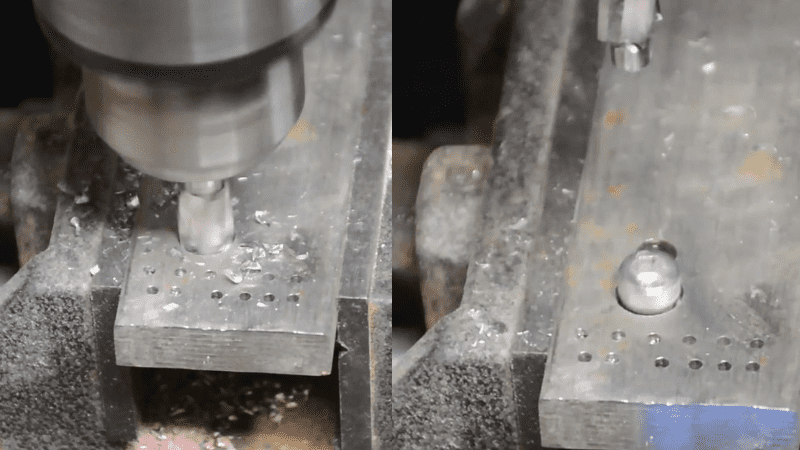

How to Create a Counterbored Hole

What Tool is used to Counterbore?

A counterbore drill bit is a versatile tool that can be used to create a counterbore on the backside of a hole. This type of bit is typically used in situations where it is not possible to drill a counterbore from the front side of the workpiece.

In addition to being able to create counterbores, a counterbore drill bit can also be used to spot face holes. A counterbore drill bit consists of a pilot drill bit that is used to create the initial hole, and a counterbore Cutting tool that is attached to the pilot bit.

The counterbore cutting tool has a flat bottom that is used to cut the counterbore, and a lip that is used to spot face the hole.

Use Counterbore Drill Bits to Create the Initial Hole

What is the Major Difference Between Counterboring and Spotfacing?

Counterbore and spotfacing are both machining processes used to enlarge the diameter of an existing hole.

The main difference between the two is that counterboring produces a shoulder at the bottom of the enlarged hole, while spotfacing results in a flat surface that is always at right angles with the axis of the hole.

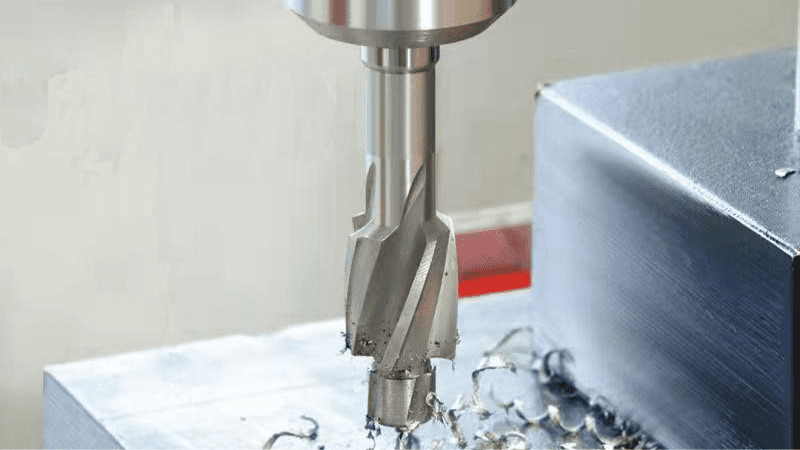

Counterboring is usually performed using a counterbore drill bit, which has a flat bottom and cutting edges that extend around the perimeter of the bit.

This type of bit is designed to produce a smooth, flat surface at the bottom of the hole. Spotfacing, on the other hand, can be achieved with either a spotface cutter or a counterbore drill bit.

When using a counterbore drill bit for spotfacing, the cutting edges are typically ground flush with the bottom of the bit, resulting in a sharp, angular edge. This angled edge produces a clean, crisp cut that is perfect for creating a flat surface.

Counterbore Drill Bits for Effective Drilling

What is the Difference Between Counterboring and Countersinking?

A counterbore is an enlarged counterclockwise-tapering hole, with a flat bottom and a shoulder, that is produced by a counterbore drill bit. It is used to house a head of a cap screw, or other large-diameter fastener whose head diameter is larger than the body of the fastener.

A counterbore may also be used to enlarge the major diameter at the bottom of a through hole so that it will accommodate a close-fitting transactional component, or to prepare a surface for spotfacing.

In contrast, a spotface is usually smaller in diameter than the rest of the hole and is located at right angles to the axis of the hole. It creates a smooth, level surface for mating parts or for bearing contact.

A counterbored hole has greater resistance to pull-out than either a drilled or reamed hole of the same size because there is more material surrounding the root of the thread in the form of a shoulder. A counterbore may be created with either a single- or multi-flute counterbore drill bit. Multi-flute counterbores are more commonly used in high volume production applications.D

Counterbore Drill Bits with #45 Steel

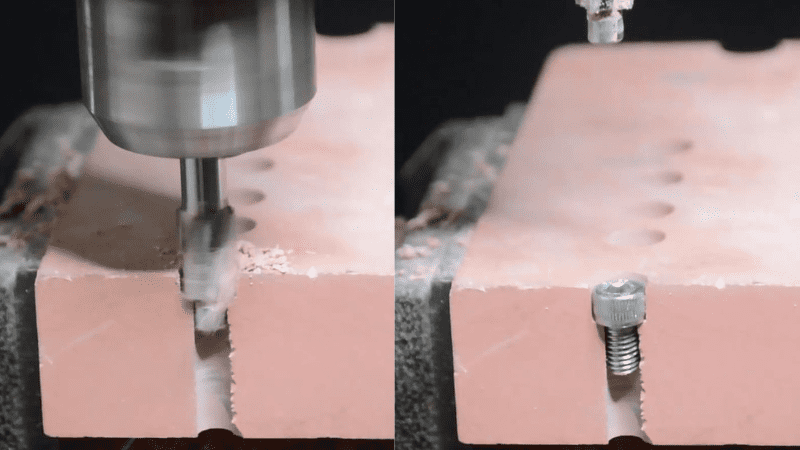

What Would be the Advantage of a Counterbore over a Drilled Hole?

A counterbore is a type of drill bit that is used to enlarge the opening of a hole so that a screw can fit flush with the surface of the surrounding material.

This can be especially useful when creating an assembly that needs to be secure, as lock washers can be used in conjunction with counterbored holes to help ensure that everything stays in place.

In addition, counterboring can also help to prevent wood splitters from breaking through the surface of the material. As a result, counterboring provides a number of advantages over simply drilling a hole.

Counterbore Drill Bits Advantage for Drilling

How do you Counterbore a Hole?

A counterbore drill bit is a type of drill bit used to create a hole with a flat bottom. It is used when it is necessary to countersink a fastener such as a screw or bolt.

When using this type of bit, it is first necessary to drill a pilot hole. This is typically done with a standard drill bit that is the same diameter as the shaft of the fastener.

Once the pilot hole has been created, the counterbore drill bit can then be used to create the larger-diameter hole with the flat bottom. The term counterbore is thought to come from the fact that this type of drilling creates a counter sunk hole.

How to Counterbore a Hole

What is a Counterbore Pilot?

A counterbore is a rotary cutting tool with a pilot tip that guides the cutting lips into the hole.

Counterbores are available in a variety of styles and sizes for specific applications. The most common type of counterbore is the counterbore drill bit, which is used to create a counterbored hole.

This type of counterbore has a pilots tip that helps to keep the bit centered in the hole and prevent it from walking. Counterbore drill bits are available in a variety of sizes and configurations to suit different applications.

[toc]